Sprinkler and deluge extinguishing. Water extinguishing installations

The initialization (operation) of automatic systems (installations) of sprinkler fire extinguishing occurs from the activation of thermal locks of irrigators directly above the ignition zone.

Below is one of the algorithms for the operation of a sprinkler fire extinguishing installation:

In standby mode (before a fire) all pipelines of the installation, including the supply, supply and distribution pipelines of the sprinkler sections, are filled with water and are under pressure, which supports the jockey pump, which is switched on and off by electric contact pressure gauges.

When a fire occurs, sprinkler sprinklers over the fire are opened. As a result of this, the pressure in the system of supply and distribution pipelines drops, the control unit valve opens, and water from the annular fire water supply is supplied to the fire source. The pressure alarm in the piping of the control unit of the sprinkler section is triggered. The “Fire” signal is supplied to the automatic fire alarm system.

The consumption of OTV (fire extinguishing substance) through sprinkler sprinklers leads to a decrease in pressure in ring fire water supply and triggering of electrical pressure gauges on the pressure head of the pump station, which give a signal to start the main pump. The main pump is turned on, which draws water from the water tank for fire fighting, it maintains the necessary pressure and flow rate of OTV in the pipeline network. If the main pump does not work or do not reach the rated power within 10 seconds, the backup pump will automatically start.

After each control unit, liquid flow alarms are installed on the supply pipe, from which the feed control signal is removed extinguishing agent (OTV).

Unlike sprinkler fire extinguishing systems sprinklers of deluge systems do not have thermal locks and, accordingly, such systems are launched from external fire detection systems: automatic fire alarm installationssensors of technological equipment and other incentive systems.

Below is one of the operation algorithms. deluge curtains:

The launch of the deluge curtains is subject to the condition that the manual shutter of the curtain is open, according to the signals:

Automatically, when two fire detectors are triggered in one of the fire compartments near the corresponding section in the automatic address-analog fire alarm system (the signal about the opening of the electromagnetic valve in the deluge sections is supplied from the APS).

. from the remote start button of the drencher in the guard room.

Thus automatic water extinguishing systems are currently the most used and common (fairly cheap) systems that do not require urgent evacuation of personnel.

Develop along with overall technological progress, offering increasingly effective security features. It is enough to note the variety of powder mixtures, including a mass of active components that suppress ignition. Nevertheless, water fire extinguishing remains the most affordable in terms of organization and price, which organically complements modern means of delivering material to a fire source.

Features of water as a means of fighting fire

The main advantage of water in the context of eliminating sources of ignition is environmental cleanliness, relatively high efficiency and, as a consequence, versatility. This resource is used at production facilities, in public buildings and in the private sector. However, water and foam fire extinguishing is not recommended for use in fire fighting, if there is a risk of damage to property and electrical equipment. Here, the property of water as an electrical conductor is already of negative importance. In addition, the use of water is not possible at low temperatures - for example, in the winter or in conditions of production operating at low temperatures.

As for the ability of this material to extinguish fire, the effectiveness of the fight is determined by the process of lowering the temperature of the outbreak due to the heat capacity of the water. In addition, such fire extinguishing systems contribute to the cessation of hazardous chemical reactions that accompany combustion.

Designs of water extinguishing installations

To implement the water supply function, almost all systems use high-pressure pumping stations that operate by electric motors. In order to increase reliability at the enterprises, backup pumps are also installed, installed on a single platform with the main unit. To perform the irrigation task, spray modules are used. They can have a different configuration of placement, sizes, feed frequency, etc.

IN latest installations modules are used to work with finely dispersed water. In addition, water fire extinguishing involves the presence in the technical infrastructure of switchgears. This is an intermediate module that connects the water supply network and the channels through which material is fed to individual irrigation devices. For the organization of a reliable plumbing infrastructure, stainless steel components are used that are oriented to operation under conditions of high temperature loads. The use of plastic materials from polyvinyl chloride, popular in plumbing, for example, is excluded in this case.

Sprinkler water extinguishing

Systems of this type are based on water supply networks constantly filled with water under optimal pressure. Technical infrastructure is most often located in the upper part of the premises - for example, under roofs or in a sub-ceiling niche. A separate water line is allocated to supply the canals. Directly supplying water to the target area is carried out by sprinklers, that is, irrigating sprinklers.

The exhaust devices are equipped with special nozzles, which under the influence of high temperatures melt, freeing the passage for water. In modern versions, water extinguishing sprinkler installations do not supply directly, but drip. Moreover, the fraction of droplets is so small that during operation, water fog forms, covering the space of the room. This decision is just caused by the desire to minimize damage directly from water to property located in the service area.

The device of deluge systems

Drencher units may resemble the previous version of the fire extinguishing system, but it has several fundamental differences. Firstly, the drencher tips are not designed for self-removal under the influence of fire. They do not burn and do not melt and, on the contrary, are made of materials with thermal protection. Secondly, the activation of the extinguishing function, that is, the irrigation process itself begins only after a signal from the fire sensors or after a manual start from the operator console. These can be water and foam fire extinguishing installations, which in normal standby mode are not filled with working material. The supply of the same water to the delivery channels to the nebulizers begins only after an appropriate extinguishing command. Therefore, the heads of the irrigators are always open.

Typically, deluge systems are used in industrial plants to cover specific areas. There is also a spray pattern for border areas, the protection of which is aimed at preventing the further spread of fire.

Creating a fire extinguishing system project

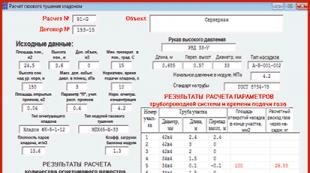

Development of a design solution is based on several factors of system operation. First of all, a pipeline scheme is formed that will provide the ability to maintain sufficient pressure when extinguishing with water in a specific facility. The pipe diameter, the configuration of their laying, the connection method, etc. are calculated. Next, calculate the optimal parameters of power equipment.

The main power unit will be the pump. Its power is estimated based on the needs of a particular room in coverage by sprayers. The fact is that the design of water fire extinguishing must also take into account the possible intensity of fire - the higher the threat, the greater the number of sprayers must be present in the room. Accordingly, the total demand for the power potential of the pump is derived. Based on the data obtained during the design process, the performers are already beginning installation activities.

Installation of fire extinguishing systems

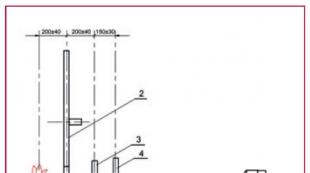

The equipment installation process consists of three main stages. At the first stage, a water supply network is laid, through which water will be supplied. Pipes are mounted taking into account high loads and the possibility of maintaining high pressure. The complexity of this event is that the water supply channels should be located in the upper part of the room. Therefore, initially, the design of the premises should also include a special niche for communications. At the second stage, the installation of water extinguishing requires the connection of a pumping station. It will be installed at the place of water intake or the connection of the pipeline to the supply central network.

It is desirable to provide a small platform for the pump, which can ensure the stability of its position. If the unit is electric, then access to the outlet should also be provided. At the final stage, the installation of spray devices - sprinklers or drenchers is performed. They are integrated into the ceiling niche by means of special fittings and connected to the supplied channels of the fire extinguishing water supply line.

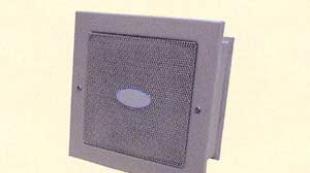

Spray Accessories

Manufacturers of fire extinguishing systems regularly improve water spray devices, offering technological fittings. When developing a fire extinguishing system project, it will not be superfluous to think over attachment systems for irrigators for more reliable operation. In particular, experts recommend the use of flexible ends made of corrugated stainless pipes. This solution is specifically designed to integrate the same sprinklers in the design of suspended ceilings. Also, to ensure durability, water fire extinguishing is recommended to be protected from accidental mechanical influences. To do this, you can use small metal grilles, frames, and even mask caps. But it is important to keep in mind that when starting the system, such devices should immediately recline.

Automation in fire extinguishing systems

And deluge, and can be automated. This means that the system will be controlled without operator intervention. Are being implemented automatic systems extinguishing using controllers and sensors - a basic set of modern fire alarms. As for the controller, its tasks include sending a signal to extinguish to the module that opens the water intake valves to the spray nozzles, notifying the person in charge of the fire, and starting the pump station. Automatic water fire extinguishing is also possible without sensors. These are devices that directly record the fact of fire, transmitting the corresponding signal to the controller.

A water and foam fire extinguishing system is the most commonly used method for eliminating a fire. Such a system can be used in any room, it is very convenient to use and affordable. Water extinguishing device requires a small amount of water to eliminate fire over a wide area. Water extinguishing system is divided into:

Sprinkler - A network of pipelines constantly filled with water, on which irrigators (sprinklers) are located. The sprinkler is equipped with an easily melting nozzle, which melts when a fire appears and the temperature rises and opens the flow of water. Such a system creates a water cloud, which significantly reduces water costs and reduces damage to the structure.

Deluge - the valves of such a system are always open, and water is supplied to them by the signal of the fire alarm system. Such a fire extinguishing system is suitable for creating a water curtain to prevent the spread of ignition.

Water extinguishing installations cool the burning structures to the desired temperature, and, therefore, terminate the chemical reaction of combustion.

Water fire extinguishing system - from 300 000 rubles

Automatic water fire extinguishing is one of the safest methods for eliminating fire and spreading fire in rooms in which there are a large number of people. The water used to extinguish a fire is absolutely safe and harmless to human health and life.

The cost of a water extinguishing system depends on the size and type of objects. Our staff will make all the necessary calculations and draw up a detailed estimate for you.

Purpose of the water extinguishing system

Powder fire extinguishing systems are used to implement fire protection various constructions, buildings and objects with a vast area. Fire extinguishing sprinkler systems are used at such facilities as:

Residential buildings

Shopping centers

Hotels

Fire alarm systems are used to ensure safety:

Manufacturing enterprises

Office buildings

Storage and hangars

Low temperature rooms

Advantages and disadvantages of a water extinguishing system

| Water extinguishing installation has a number of the benefits, namely: Fast response in case of fire Effective and reliable fire neutralization Cost-effectiveness Availability and low cost Convenience and ease of use The ability to supply water over long distances |

Despite the large number of advantages of such a system, it has some limitations:

It is forbidden to extinguish electrical equipment with water, as water has electrical conductivity Possible extensive damage to property and facilities by the extensive flood of water Lack of application unattended installation fire extinguishing in rooms containing objects of historical and cultural value |

Calculation, design, installation and installation of water and foam fire extinguishing systems

![]() The Alliance Monitoring company provides high-quality and professional services for the creation of the project, as well as for the maintenance, installation and installation of water and foam fire extinguishing installations. In our company you can order the creation and installation of the system you need at a low price. We use only proven systems and structures and reliable materials, so that we can guarantee long-term and high-quality operation of any fire protection system.

The Alliance Monitoring company provides high-quality and professional services for the creation of the project, as well as for the maintenance, installation and installation of water and foam fire extinguishing installations. In our company you can order the creation and installation of the system you need at a low price. We use only proven systems and structures and reliable materials, so that we can guarantee long-term and high-quality operation of any fire protection system.

We provide our customers with an accurate and detailed calculation of the installation or maintenance any system, and you can purchase a water fire extinguishing device, as well as the services you need at a favorable and optimal price in our company.

Normative documents regulating the installation and use of water fire extinguishing systems

1. Sprinkler installations for water and foam fire extinguishing, depending on the air temperature in the premises, should be designed:

water-filled - for rooms with a minimum air temperature of 5 ° C and above;

air - for unheated rooms with a minimum temperature below 5 ° C.

2. Sprinkler installations should be designed for rooms with a height of not more than 20 m, with the exception of installations designed to protect structural elements of the coatings of buildings and structures. In the latter case, the parameters of the installations for rooms with a height of more than 20 m should be taken for the 1st group of rooms (see table. 1.1.5).

3. For one section of the sprinkler installation, no more than 800 sprinkler irrigators of all types should be taken. At the same time, the total capacity of the pipelines of each section of air installations should be no more than 3 m 3.

4. When using the control unit with an accelerator or an exhauster, the capacity of the pipelines of air units can be increased to 4 m 3.

5. Each section of the sprinkler installation must have an independent control unit.

6. When protecting several rooms or floors of a building with one sprinkler section, it is allowed to install a signal indicating the tanning address, as well as turn on warning and smoke exhaust systems on supply pipelines, excluding annular, liquid flow alarms.

7. Sprinkler sprinklers of water-filled AUPs are installed vertically by sockets up or down or horizontally, in air AUPs - vertically by sockets upward or horizontally.

8. Installation of sprinkler sprinklers should be made in such a way that the sprayed or sprayed stream of water of the activated sprinkler does not directly affect adjacent sprinklers.

9. Within the same protected premises, the same type of sprinklers should be installed with the same outlet diameter.

10. The distance between sprinkler sprinklers and walls (partitions) with a fire hazard class Kl must not exceed half the distance between sprinkler sprinklers indicated in Table. 1.1.2.

11. The distance between sprinkler sprinklers and walls (partitions) with a non-rated fire hazard class should not exceed 1.2 m.

12. The distance between the sprinkler sprinklers of water extinguishing installations installed under smooth ceilings (coatings) should be at least 1.5 m.

13. It is allowed to connect fire valves of the internal fire water supply pipe to the supply pipelines of water-filled sprinkler AUPs with a diameter of 65 mm and more.

14. The duration of the internal fire hydrants equipped with manual water or foam fire barrels and connected to the supply pipelines of the sprinkler installation should be taken equal to the operating time of the sprinkler installation.

15. The design of internal fire hydrants should be carried out according to SNiP 2.04.01-85 *.

The main sources used: NPB 88-2001, GOST R 50680, GOST R 50800

1. Automatic inclusion of deluge installations should be carried out according to signals from one of the types of technical means:

Incentive systems;

Fire alarm installations;

Sensors of technological equipment.

2. The induction pipeline of deluge units filled with water or a foaming agent solution should be installed at a height relative to the valve not exceeding 1/4 of the constant pressure level in the supply pipe, or in accordance with the technical documentation for the signal valve used in the control unit.

3. For several functionally related deluge curtains, it is allowed to provide one control unit.

4. The inclusion of deluge curtains may be made either automatically when the fire extinguishing installation is triggered, or manually (remotely or locally).

5. The distance between the sprinklers of the deluge curtains should be determined on the basis of ensuring the flow rate of water or a foaming solution of 1 l / s per 1 m of the width of the opening. When installing deluge curtains in two or more lines, located at a distance of no more than 0.5 m from each other, the total water flow should be at least 1 l / s per 1 m of the curtain with a duration of at least 1 hour.

6. The distance from the thermal lock of the incentive system to the plane of the overlap (coating) should be from 0.08 to 0.40 m.

7. To increase the speed of deluge AUP and reduce the degree of corrosion of the inner surfaces of the supply and distribution pipelines, it is allowed to fill them with water to the level of the lowest located deluge sprinkler. If sprinklers have easy-to-reset plugs or caps, it is allowed to fill the supply and distribution pipelines completely with water; at the same time, to remove air at the highest point in the pipeline system, it is necessary to install a crane with an outlet diameter of not more than 10 mm.

Scheme of working with us

To order quality and professional service, installation and installation of a water fire extinguishing system at an attractive price, the Alliance Monitoring company needs to:

Call us at the telephone number indicated on the website

Alliance Monitoring will analyze your facility

We will prepare a detailed calculation of the cost of the services you need and form an offer

In the shortest possible time we will carry out all necessary work on the fire treatment of your facility

After the completion of all work, we will hand over the finished object and provide related documentation

Benefits of working with us

The Alliance Monitoring company provides only first-class fire-fighting services and the installation of any fire-fighting systems. When ordering the design and installation of a water fire extinguishing system in Alliance Monitoring, you get:

Licensed, professional and fast provision of all services at an attractive price

Certified materials with quality components

Guaranteed fire prevention in case of fire

We guarantee high quality, as well as long-term and reliable operation of the powder fire extinguishing system of our company, so you can ensure safety for your facility and employees.

Or sprinkler sprinklers through which water is evenly distributed over the entire area of \u200b\u200bthe surface to be protected. Water extinguishing - One of the most economical and inexpensive fire extinguishing systems.

Automatic water fire extinguishing is one of the safest ways to combat the occurrence of fires in rooms where a huge number of people are constantly present. In addition, the water used to extinguish is safe and does not pose a threat to human life and health.

The Alfa TV Com company carries out competent design of water fire extinguishing, reliable installation and high-quality after-sales service. Turning to us, you will receive an effective fire extinguishing system at the most affordable price.

Types of water extinguishing systems

Structural fire extinguishing is divided into:

- Water sprinkler fire extinguishing: water extinguishing sprinkler systems they fire as they heat, that is, directly above the source of ignition, which makes them indispensable for the localization of the flame.

- Water deluge fire extinguishing : fire extinguishing systems trigger simultaneously with the alarm and prevent the spread of combustion products to other rooms. As a rule, they are installed in the window and doorways of the building to isolate the fire from other rooms.

Offer from Alfa TV Com

Alfa TV Com specialists are ready to design and install water extinguishing systems on all existing types of facilities, even on the most complex ones. When installing a fire extinguishing system, we use only reliable and modern equipment, which allows us to achieve high efficiency of the installation.

![]()

Contact us, right now and in the shortest possible time you will have a reliable water fire extinguishing system!

Automatic water fire extinguishing systems are used to automatically extinguish a fire, without human intervention.

Advantages:

- - efficiency

- - security

- - profitability

- - easy installation

Automatic water fire extinguishing systems provide automatic (without human intervention) fire extinguishing.

Main advantages:

- profitability

- ease of installation

- efficiency

- security

- object cooling

Unlike gas, water fire extinguishing may not be placed everywhere.

Subtleties in the design and installation:

- device of internal and external water supply

- support of a certain pressure in the highway

- pipe routing over the entire area of \u200b\u200bthe facility

There are several types of automatic fire extinguishing systems (AUVPT):

A system of any type consists of:

- wet

- dry

- deluge

- booster pump station (including pumps, consoles and control units, signaling devices, valves and supply piping)

- sprinkler or deluge network (including sprinkler or deluge sprinklers, piping with mounting elements, stop valves, signaling devices).

Automatic water fire extinguishing systems are currently becoming increasingly common. Water has been extinguished by fires at all times, and nowadays water is recognized by the majority of experts as a means No. 1 in the fight against fire.

This type of system is used to protect shopping and business centers, office buildings, sports complexes, hotels, enterprises, warehouses, garages and parking lots, banks, energy facilities, military and special purpose facilities, residential houses and cottages. We pay attention to fire extinguishing the server this type of fire protection is not suitable. If necessary, individual fire extinguishing design is possible.

Turning to the company LLC GlavMontazhProekt, you will receive qualified assistance from our experienced specialists, we will answer all questions regarding the selection of the necessary equipment.

Cooperating with us you get a reliable water fire extinguishing system.

Automation of fire extinguishing installations on the basis of Bolid equipment

The use of fire extinguishing installations allows to prevent the spread of fire in a sheltered room, as well as minimize the likely damage that may be caused to property by fire, combustion products and technological installations used to combat fire.

There are several types of classification of automatic fire extinguishing installations: by the type of extinguishing agent (water, gas, powder, aerosol), by the method of extinguishing (by volume or by surface), by the method of organization (modular or centralized), by the method of control (autonomous or complex) etc. The most common types of installations are:

- Gas modular and centralized installations;

- Powder plants;

- Water centralized installations.

Gas installations

As a fire extinguishing agent in gas installations, liquefied or compressed gas is used, which is stored in special isometric containers or pressure cylinders. The physical principle of quenching in such installations is based on the displacement of oxygen by a heavier gas that does not support combustion. In this case, the quenching occurs either locally in volume or in the entire volume of the room. Typically, this extinguishing method is used to protect certain categories of rooms with a sufficient degree of tightness and, most importantly, with a limited stay of people. Work gas installation in automatic mode, it should exclude the possibility of the release of extinguishing agent in the event of the presence of people in the room, while the operation of the installation itself in an alarm mode should be accompanied by sound and light alarms, forcing people to leave the room.

In view of these requirements, the installation, as a complex technical complex of means, should provide the following functions:

- Control of automatic fire detectors;

- Launch control of fire modules;

- Management of sound and light annunciators;

- Health monitoring gas modules;

- Closure control doorways;

- Implementation of automatic remote and local installation startup modes;

- Lock automatic or remote start in the presence of people.

In the case of modular installations, control devices and gas cylinders can be located in the room itself, while the capacity of the cylinder is determined based on the volume and degree of leakage of the room. That is, if any leakage of a fire extinguishing agent is possible from the room that is equipped with a fire extinguishing installation, they must be provided for when choosing the capacity of the cylinder. The tank capacity should compensate for these leaks. If the installation protects several rooms, as a rule, a centralized gas station is designed. Usually such a station takes separate room, in which all pipelines from the protected premises are reduced, and in which a gas cylinder battery is installed, or one single tank with compressed or liquefied gas. In this case, the amount of extinguishing gas is normalized either by the number of cylinders (in the case of a gas battery), or by the time of supply of the extinguishing gas (in the case of a total capacity), which should provide a fire extinguishing in a certain room. The disadvantages of gas extinguishing are the high cost of fire extinguishing gas and the danger to human health, but its main advantage is the complete absence of material damage to objects and equipment located in the room. To eliminate the effects of extinguishing, it is enough to ventilate the room, for example, using special installations.

An example implementation of a small standalone installation gas fire shown in figure 1. The room has a suspended ceiling and a raised floor, forming hidden volumes, which are protected by independent alarm loops. The functions of monitoring fire detectors, controlling sirens, monitoring the health of a gas cylinder and the functions of a fire extinguishing control device are performed by the S2000-ASPT device. The door status sensor allows you to block the start when entering / leaving the room; the reader is designed to remotely turn on or off the automatic mode, and the manual start button allows you to remotely activate the installation start mode.

Figure 1. Autonomous gas fire extinguishing installation

Powder Extinguishing Systems

A widespread category of installations is powder extinguishing installations. These units can also be used for local or central fire extinguishing and can be used in rooms with people present, since the powder used in them is non-toxic and cannot cause direct harm to human health. The physical principle of extinguishing is the formation of a powder cloud, which covers a certain area of \u200b\u200bthe protected premises. In this case, the powder particles cool the surface, and the gaseous products of its thermal decomposition dilute the combustible medium, preventing the development of a fire. In addition, the formation of a powder cloud in narrow passages or channels has a certain fire retardant effect. In centralized (or aggregate) installations, the powder is stored in a common tank, and the amount of powder supplied to the common collector is determined by the area of \u200b\u200bthe room. In local (or modular) installations, fire extinguishing powder is stored in special modules containing a launch device (usually an electric squib) and a compressed gas cylinder, which, if activated, atomizes the powder to form a cloud. The number of powder modules and their type is determined by the area and features of the protected premises, as well as the method of their fastening.

The advantages of powder plants over gas are lower cost, shorter recovery time and relative safety for people. The disadvantage is the rather high complexity of powder cleaning after the installation is triggered.

An example of the implementation of a local extinguishing powder installation is shown in Figure 2. The S2000-ASPT device is used as a control panel and installation control device. To start the powder modules, the S2000-KPB control and starting unit was used, which monitors the health of starting circuits in standby mode and activates the module in case of fire extinguishing. The S2000-KPB device is controlled by the S2000-ASPT device via the RS-485 interface.

Figure 2. Local extinguishing powder installation

Water extinguishing installations

Historically, automatic water extinguishing systems have received the most widespread use. Water is the cheapest and safest fire extinguishing agent that allows you to effectively protect objects that are characterized by a large concentration of people: shopping centers, office rooms, hotels. Water, as a fire extinguishing substance, does not pose an immediate danger to humans and other living things. Water fire extinguishing systems are also used to protect open (leaky) objects: multi-level parking lots, garages, boxes, where gas and powder fire extinguishing systems are ineffective.

The principle of action of water as a fire extinguishing substance is cooling and isolation, due to the formation of steam, from atmospheric oxygen of the surface at the ignition site, as a result of which the combustion process stops. Extinguishing in this case occurs on the surface of the protected premises. The physical restrictions that water imposes as a fire extinguishing agent include the following: the inability to use such a plant at low (below zero) temperatures, as well as for extinguishing electrical installations.

Water extinguishing systems, as well as gas fire extinguishing systems, can deliver extinguishing agent locally to the place of ignition (sprinkler section), or extinguish the total area of \u200b\u200bthe protected space (deluge section).

Sprinklers are opened locally, when the temperature lock is triggered, above the place of a possible fire. The deluge sections consist of a set of open irrigators. The extinguishing agent is supplied to them when the general electromagnetic valve is opened, controlled by the control panel of the fire alarm system. Fire detectors are connected to the loops of such a control panel, when triggered, a valve control command is generated.

One of the promising areas of water fire extinguishing is the installation of extinguishing with finely dispersed water. Fine fire water extinguishing installations combined the advantages of gas and water fire extinguishing at the same time. The main advantages include a low consumption of extinguishing agent, less substantial costs (since water is cheaper than gas), and no harm to human health.

In addition to the limitations associated with electrical conductivity and freezing of water at low temperatures, the disadvantages of water fire extinguishing systems include the potentially high damage to property and high labor costs in eliminating the consequences of the installation.

Figure 3 shows a water fire extinguishing system implemented on the basis of the Potok-3N device.

Figure 3. Water extinguishing system

The main unit of the automatic water extinguishing system is a pumping station. Inside the station, the necessary shut-off valves (electric valve), pumps (main fire, standby, leakage compensation pump), control cabinets for pumps and actuators, and additional equipment are installed. The Potok-3N device has a set of inputs (monitored circuits), which are designed to connect sensors (electro-contact pressure gauges, flow sensors), signal circuits of electro-valves and starting devices. The device allows you to start the water fire extinguishing system according to several conditions: a drop in water pressure in the system, triggering of the start button, remote control commands (when working as part of the system). If one of the start conditions occurs, the device sends control signals to the pump control cabinet - ShKP (control and start-up cabinet). In case of blocking of automatic switching on, the cabinet provides the possibility of local or manual control of the units. ShKP also allows you to disable all types of control. Up to 20 additional subscribers (for example, S2000-4 devices) can be connected to the Potok-3N device via an internal RS-485 (2) interface, which can be used to control additional processing equipment.

The considered water fire extinguishing system can be used both in residential and non-residential premises. Sprinkler sections can be used to protect open premises (parking lots, shopping malls) in places where it is not possible to install smoke detectors (high dust content), or it is not advisable to extinguish the entire area (due to its size). Drench sections or curtains can be used to protect relatively small areas, or rooms where fire can spread quickly.

Centralized fire extinguishing control system

Often, there is not one but several fire extinguishing zones at the facility. Moreover, in each zone can be used various installations fire fighting. When it is necessary to combine several of these areas and bring the monitoring and control function of equipment to the security post, you can use the S2000M control and control panel, as well as display and fire extinguishing control units. The S2000-PT unit is used to work with the S2000-ASPT and can control and display up to 10 fire extinguishing directions. Block "S2000-BI" isp. 01 is designed to work together with Potok-3N, it allows you to display the status of up to 35 security sections, 5 pumps and a pumping station. Consider a few examples of centralized systems.

Figure 4. Centralized system automatic fire fighting with modular installations

Centralized powder fire extinguishing system

The system in Figure 4 is constructed as follows. Fire extinguishing devices responsible for the protection of each direction are combined with the RS-485 interface with devices located at the guard post (remote control, display unit). Each fire extinguishing direction in the database of the S2000M console is assigned one section, current information about each section is transmitted by the console to the S2000-PT unit and displayed on the block indicators. If necessary, by pressing the “START” and “AUTOMATIC” buttons of the unit, you can initiate commands to turn on / off the automatic start mode or start / reset fire extinguishing in each direction. It should be borne in mind that all teams on remote control fire extinguishing equipment is formed only by the S2000M remote control, and the S2000-PT unit is just a tool to initiate them.

If necessary, a generalized fire warning and automatic start signaling can be implemented at the guard post. For this, each section (fire extinguishing direction) can be assigned control of one (or several) outputs of the S2000-KPB block, in accordance with the available management tactics (programs). It is worth noting that such a construction of the system involves two levels of control. The first level: control of automatic fire extinguishing installations at the place of ignition - is provided by the S2000-ASPT device, the second level: remote control and control of each direction is provided by the C2000M control panel. With this configuration of the system, even if an interface line malfunctions during a fire, the entire set of necessary measures to extinguish the fire will be performed automatically, without the participation of a network controller.

Centralized gas fire extinguishing system

An example of building a more complex fire extinguishing system, with primary and backup gas batteries, is shown in Figure 5.

Figure 5. Centralized automatic fire extinguishing system with gas battery

The wiring of the pipeline supplying the extinguishing agent from the gas battery in the directions of fire extinguishing assumes the presence of a shut-off valve at the outlet in each direction. A pressure signaling device (CDS) is also installed there, it is also a sensor for extinguishing agent output. The system is built similarly to the previous one, however, in this case, the control function fire automatics are divided between the “S2000-ASPT” device and the “S2000M” remote control. The system works as follows: when conditions arise that enable the installation of gas fire extinguishing, the device “S2000-ASPT” generates a “start” message and opens the shut-off valve included in its start-up circuit. The “S2000M” remote control, having received a message about starting in a certain direction, includes the outputs of the “S2000-KPB” block, which open a given number of cylinders in the installation. Fire extinguishing gas enters the common pipeline and exits through an open valve into the burning room. As soon as the gas pressure at the inlet of the pipeline into the room reaches the preset value, the pressure signaling device trips, the S2000-ASPT device sends an extinguishing message in this direction to the S2000M control panel, and the “Extinguishing” indicator lights up on the S2000-PT unit.

If the device “S2000-ASPT” has not detected the triggering of the pressure switch within a specified time after the shut-off valve is opened, the “S2000M” remote control will receive the message “Unsuccessful start” in this direction. Upon receiving such a message, the console will turn on the outputs of the “S2000-KPB” block, which are responsible for opening the cylinders of the backup gas battery. Thus, the control function of the redundant central gas fire extinguishing installation will be implemented.

The logic of the system is as follows. Control panels are combined with a common information RS-485 interface with the Potok-3N device (Figure 6). Also at the guard post there is a display unit “S2000-BI” for visual display of the status of the pumping station and fire sections. In the configuration of the S2000M remote control, special control scenarios have been created that allow the fire extinguishing to be carried out when a fire is detected by control panels.

Figure 6. Centralized water extinguishing system

Also, in some cases, it is required to start an automatic fire extinguishing installation from address-analog detectors. For example, if an automatic fire alarm, then install additional detectors that will be monitored by the fire extinguishing installation, it makes no sense. In such cases, the devices to which the APS detectors, fire extinguishing control devices and, if necessary, auxiliary devices are connected, are connected by an RS-485 interface under the control of the S2000M remote control. In the S2000M console, sections are formed where APS detectors are added, and special control scenarios are created. Each fire extinguishing direction is assigned a corresponding section. An example of such a circuit is shown in Figure 7.

Figure 7. Extinguishing system using an address-to-analog fire alarm

In certain cases, when one of the main factors in choosing a fire extinguishing system is the price, it is possible to assemble a fire extinguishing system using only control panels (for example, the Signal series) or an address system, as well as S2000-KPB control and launch units under remote control "S2000M". In this case, all the logic of the system must be programmed in the network controller manually. For example, in the presence of a large number of extinguishing directions, it is economically more profitable to use a circuit of one or two controllers of a two-wire communication line and control and start-up blocks than using a large number of S2000-ASPT devices. However, such a system, despite its cheapness, has a number of drawbacks: it is impossible to distinguish between manual (remote) start from automatic; no switching of the modes of automatic / manual start. That is, the use of this equipment can be limited only to those facilities where people are expected to stay, and extinguishing occurs when automatic sirens are triggered. An example of such a circuit is shown in Figure 8.

Figure 8. Fire extinguishing system based on "S2000-KDL" and "S2000-KPB" devices