Maintenance of automatic fire extinguishing installations. Features of the equipment and scope. Features for various equipment

Most modern buildings are characterized by high altitude, so they are subject to special fire safety requirements.

One of the most important measures is rightfully considered to be the installation and maintenance of fire extinguishing systems that can detect the occurrence of a fire in the early stages, notify a person about it, localize a fire and eliminate the accident automatically.

Composition of modern fire extinguishing systems

Based on requirements normative documents The development and installation of an automatic fire extinguishing system should only be carried out by specialized organizations that have the appropriate licenses. Any mistake at these stages, as well as during the maintenance of such systems, can lead to irreparable consequences, including loss of life.

Not so long ago, such systems were mainly required only on an industrial scale, production facilities of various hazard levels were considered the main place of their operation. The development of civil engineering, the emergence of many residential high-rise buildings, shopping and entertainment centers has clearly demonstrated the need for such systems for all buildings, without exception.

The bulk of modern systems to prevent fires and their elimination are a whole range of technical equipment that can work in automatic mode.

The composition of the equipment without fail includes the following subsystems:

- Fire Detection They traditionally include sensors capable of detecting a temperature increase in a controlled room, the appearance of potentially dangerous concentrations of carbon monoxide, which is one of the signs of fires.

It is the detection of such factors at the very early stage of a fire that is the key to successful containment and liquidation of an accident with the least losses for owners.

- The next main task that needs to be addressed is to alert people about an accident. It is on this that their timely evacuation and rescue depends. All warning devices can be divided into sound and light devices, indicating the way out of a burning building.

- The immediate liquidation of an accident is carried out by water, gas or powder fire extinguishing systems.

- Additional devices include actuators that allow opening doors on escape routes, start smoke exhaust and ventilation systems, fire pumps and other equipment.

Consider work and maintenance various systems fire fighting in more detail.

Water is the first substance that has been used to extinguish fires. Modern water extinguishing systems are reliable and efficient.

But it should be remembered that the use of extinguishing water can lead to failure of electrical equipment, damage the interior decoration of buildings.

In order to minimize the effects of liquids, finely dispersed nebulizers have been used recently as actuators. This allows you to turn water into almost a fog, which fills the entire volume of the room and leads to extinguishing an open flame, while the water flow, therefore, the possible damage is significantly reduced.

Water fire extinguishing systems include a number of technical devices. Therefore, maintenance of fire extinguishing (all applicable means) should be carried out by specially trained personnel in a timely manner. In this case, it is assumed not only an external inspection and visual determination of health various devices, but also practical testing of the health of all nodes of the system.

The main elements of water fire fighting:

- Fire reservoirs and reservoirs with appropriate pumping technology. All reservoirs must provide the amount of water necessary for the liquidation of the accident, while it must be possible to replenish such tanks without stopping water withdrawal. Pumping equipment must provide water supply to the most remote points of the building, therefore, units with appropriate pressure and flow characteristics are installed. During the test, the operability of all devices, switching units and other equipment used to supply water is determined.

- The main element of such a system is the fire pipeline, paved throughout the building. It should be equipped with fire hydrants, providing connection of hoses with a barrel and other extinguishing equipment. The ring circuit (with sectioning) of the pipeline laying is considered optimal for ensuring water supply from two sides of the source, this allows not to stop extinguishing when the line burns out at the ignition site.

A regular visual inspection of the pipeline, the performance of fire hydrants and valves, should be carried out regularly. In addition, the integrity of the line is checked by hydraulic tests at a certain pressure.

- Water extinguishing systems include modern foam technology. The use of foam to extinguish a fire can significantly reduce the time of localization and liquidation of the accident. In fact, such units are more powerful fire extinguishers that are driven by automation. Such aggregates require regular external inspection, determination of the state parameters of the working substances that cause foaming. In addition, all foam extinguishing equipment must be recharged at a specific time. Specialized organizations having the appropriate license should be engaged in the performance of these works.

According to the requirements of regulatory documents, all modern buildings must be equipped with means and systems of powder fire extinguishing. As the main extinguishing agent, finely dispersed powder of inert materials is used. When it is supplied under high pressure to the source of ignition, the flame breaks down, and a layer of powder formed on all surfaces prevents the access of oxygen to the burning site. Thanks to this, the fire is extinguished in the shortest possible time.

The spraying of the powder is ensured by compressed air or carbon dioxide (in this case, the fire fighting efficiency increases significantly), which is stored in special containers.

The main advantage of such systems is the complete absence of damage to the premises and equipment located in it. Unlike water, the use of the powder does not lead to additional troubles, after extinguishing the powder is quite simply removed from any surface.

Maintenance fire extinguishing installations of this type is to check the integrity of all nodes, control the amount of working gas, providing spraying of the powder. Equipment of this type should also be periodically recharged and replaced with the main active substance (powder).

This equipment belongs to the volume of extinguishing. To maintain combustion requires constant access of oxygen to the source of ignition. The principle of operation of devices gas fire It is based precisely on the displacement of atmospheric air from an emergency room and its replacement with inert gases.

As the main active ingredients, carbon dioxide or nitrogen is most often used. In some cases, mixtures with freon can be used, in this case, a temperature reduction at the fire site is additionally provided.

Maintenance consists in controlling the amount of fire extinguishing gas that is stored in cylinders. The lines of gas supply to various rooms, the operability of automation sensors that drive the device are checked. In addition, you must remember to regularly check the integrity of the cylinders, the so-called calibration should be performed in the allotted time in special organizations.

Checking the performance of automation systems

An important role is played by the operability of fire extinguishing systems control systems. Therefore, a regular check of the signaling and control circuits should be carried out, in addition, tuning and monitoring of the operability of sensors and actuators is required.

Maintenance work on any fire extinguishing system should only be carried out by specially trained personnel who have undergone appropriate training. Device maintenance must be entrusted to specialized companies.

Only in this case it will be possible to guarantee the efficiency of all devices and systems.

Powder-type automatic fire extinguishing system and its advantages

Powder-type automatic fire extinguishing system and its advantages

In ensuring the fire safety of the facility, the main role is played by fire extinguishing systems. They should work quickly and be trouble-free. In order for them to be serviceable, they need to be regularly checked and eliminated the identified problems. To do this, carry out maintenance of fire extinguishing systems. It consists of several stages and many events. Each of them is suitable for a specific case. In addition, all processes associated with fire extinguishing systems are documented.

Basic Rules

Fire extinguishing services (systems and installations) are partially performed by the owner or tenant of the facility. The head of the company appoints a responsible person, and his duties in this area are prescribed in the job description. Most of the maintenance work is carried out by a specialized organization. An agreement is concluded with her, where conditions are prescribed up to the time of departure to the object in case of an emergency call.

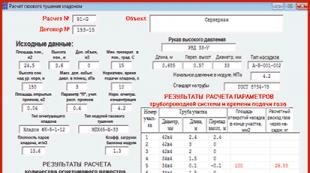

All work is regulated by document RD 25 964-90. Basic information about the timing of maintenance, technical parameters is contained in the operational documents for the fire extinguishing system or its elements. After installing the equipment, they fill out the passport to the system; it also plays a role in the checks and their identification.

Types of jobs

The following types of work are distinguished:

- visual inspection;

- preventive work;

- performance check.

External inspection allows you to determine the condition of fire extinguishing systems from a technical point of view. In the process of such maintenance of the system, a specialist conducts a visual inspection of all elements, components and assemblies, and can use measuring instruments. They reveal various defects and damages: pipe leakage, rust on metal parts, separation of elements, etc.

Preventive maintenance work must be carried out regularly. They include pipe cleaning, lubrication of mechanisms, and rust removal. The specialist should pay attention to the faulty equipment and make its replacement. It is important that the new elements are similar in parameters to the old ones. Prevention helps prevent the occurrence of malfunctions and defects in fire extinguishing systems.

Performance check - a set of technical measures aimed at checking the proper functioning of the system. Since modern systems automatic fire fighting equipped with electronics, then an external examination, prevention. The performance check should affect not only the technological part, but also the electrical part with the alarm.

The regularity of the following types of maintenance of various fire extinguishing systems:

- planned (according to the approved schedule);

- unscheduled (with false alarms, malfunctions).

Visual inspection and performance checks are carried out at least 1 time per month. The timing of maintenance work is established on the basis of information from operational documents and other data from the manufacturer.

Work stages

The first task is the mandatory search for a contractor with the appropriate authority and technical base. Inspections are accompanied by a representative of the customer (owner or tenant of the facility).

Maintenance of fire extinguishing installations begins with a study of the facility, equipment and documentation. Next, the specialist analyzes the data and proceeds to inspect the technological part. As a rule, it includes pipelines, measuring instruments and equipment, electrical equipment, valves. Then check the condition and properties of the extinguishing agent. The electrical part pays a lot of attention, as well as alarm systems. They also measure resistance and monitor the performance of all power sources. The latter are usually two - primary and backup. Maintenance work is an intermediate and important stage in the entire maintenance process.

After inspection and spot check of all elements, the turn of prevention comes. At this stage, maintenance various installations fire fighting is a kind of test. Even after all the necessary measurements and inspections, malfunctions are often detected. Then repair is possible with the elimination of defects and the replacement of faulty parts.

The service ends with the preparation of documentation on the work performed. In the end, the specialist approves the result with the customer and gives advice. Sometimes the equipment becomes obsolete and needs to be replaced; questions may arise about other parts of the system. All work and maintenance consultations must comply with regulatory documents.

Features for various equipment

Since the design of fire extinguishing systems largely depends on the type of extinguishing agent, the maintenance of water fire extinguishing will differ from the verification and inspection of the gas variant. The specialist must be competent in these matters and know the nuances of functioning and devices of each type.

Maintenance of water installations and systems involves regular determination of the water level in the tank. The inspector, during the maintenance of water extinguishing systems and installations, records data on this in a separate journal. If the level of the extinguishing agent has changed significantly for no apparent reason, then there is a high probability of detecting a leak in the tank or pipeline. Every month, a pump station is inspected; every 2 weeks, pumping equipment must be started. In water fire extinguishing systems, pressure gauges are checked for serviceability every year, and revisions of the air tank are carried out with the same frequency.

In addition to standard work, powder fire extinguishing services include monthly determination of cylinder pressure. The data are compared with the normative, as well as the quality of the powder mixture, the verification dates of which are indicated in the technical documentation. After activating the fire extinguishing agent cylinders, they purge the containers with nitrogen to clean them.

Maintenance of gas fire extinguishing systems also has its own characteristics. The amount of extinguishing agent is usually determined by weighing. There is another option - pressure control. There is a difference in this process for modular and centralized systems. After operation, refueling with a gas extinguishing agent, propellant gas is made, and failed elements (pyro cartridge, modules) are replaced. Maintenance of gas fire suppression involves inspection to identify seals, marking the module, devices from spontaneous startup of systems and installations.

Today's SPT (fire extinguishing systems) are able to independently track the current state of the controlled zone. In the event of detection of fires, or the slightest threat of a fire hazard, these complexes of mechanisms instantly reflect all the information at the checkpoint. Automatic localization of the fire after this is carried out in the shortest possible time. Proper maintenance of fire fighting is a key factor for the successful operation of the system.

SPTs have already gained sufficient distribution due to their own uniqueness and versatility. The discussed complexes successfully ensure fire safety in a wide variety of industries and organizations. We are talking about complex mechanisms that consist of a large number of algorithms. This is monitoring the status of all installed sensors, monitoring temperature thresholds, turning on sound alerts and light alarms, and automatically starting a fire extinguishing system.

The main advantages of the systems under discussion are the timely identification of a dangerous situation, as well as the ability to independently eliminate the threat of fire sources after pressing the fire alarm button alone. Various gases like nitrogen or argon, powder formulations, foam solutions and, of course, ordinary water can act as extinguishing agents.

Installation and maintenance of such a complex without fail involves a preliminary familiarization with all varieties of installations, their distinctive features, disadvantages and advantages, as well as the principles of operation at various facilities. Only a detailed study of all information can become the basis for the correct choice of system.

As of today, it is customary to distinguish three main varieties of fire extinguishing systems. We are talking about complexes that use water, specialized gases or powder mixtures. Will consider more carefully each of them.

Water extinguishing

Nowadays, the elimination of fires in buildings using a water extinguishing system is the safest and most effective method. About 90 percent of all fires are eliminated thanks to just such installations. At the same time, these systems have certain disadvantages. Their operation always implies high costs for the acquisition of water necessary to extinguish a fire. It is customary to store water in specialized drainage facilities, tanks and pumping stations. As a rule, it is required to erect special capital engineering structures. The disadvantages of water extinguishing include the considerable likelihood of causing significant damage to the building, premises or material values.

To some extent, the disadvantages can be overcome by using special technologies. We are talking about finely dispersed water, which provides for a fairly rational consumption, as well as the artificial reduction of water droplets. Indeed, according to existing statistics, in the course of extinguishing a fire using water installations, only 30 percent of the total consumption is used to eliminate the fire. Extinguishing with finely dispersed water implies the formation of water mist, characterized by high cooling and penetrating abilities. The technology allows more reliable localization and elimination of fires at a lower water consumption.

Gas extinguishing

Gas extinguishing mechanisms are also used to identify the source of fire, warning and extinguishing using a specialized fire extinguishing gas. Such systems can protect various expensive equipment from possible corrosion. The consequences of the installation are easily eliminated by the most ordinary ventilation of the room. The systems under discussion are characterized by increased resistance to low and high temperatures. They are almost ideal in rooms where electrical equipment operating under constant voltage is located.

This type of complex functions on the basis of oxygen reduction as a result of the supply of non-combustible gases directly to the ignition zone. In addition, the elimination method can be not only voluminous, but also local if necessary.

Powder fire extinguishing

According to the current fire safety and municipal services standards, in general, all administrative and public buildings, industrial or warehouse type premises must be equipped with powder fire extinguishing systems.

In this case, the flame is eliminated by instantly supplying a non-toxic, finely divided powder composition directly to the ignition zone. Convenience of operation and relatively low cost with no damage to equipment and premises are the main advantages of such plants. The results of using these systems are easily canceled by ordinary cleaning. The only drawback is the limited shelf life.

Design and installation of fire extinguishing systems

The automatic fire extinguishing installation in accordance with the applicable requirements is a whole complex of specialized technical equipment designed for the quick localization of internal fires. Such a complex includes control and management systems, sprayers and pipelines, as well as devices and reservoirs containing extinguishing agent. Installation is the most costly stage of providing the facility with reliable fire protection. It is made after designing all the necessary fire extinguishing means, as well as fire alarm.

The technical design of fire extinguishing systems implies a number of the following goals.

- The units under discussion should be as modular as possible, connected to separate control units, which increases overall operability.

- The functionality of the common and individual branches can be provided if there is wireless communication between each installation and the control unit. This fully eliminates the likelihood of failure when the low-voltage lines are broken under the influence of an open flame or high temperatures.

- The fire alarm system and the installation itself must have several independent sources of electrical power at once, although this somewhat complicates the maintenance of fire extinguishing systems.

- Places of the most likely fires must be equipped with automated powder or aerosol fire extinguishing systems.

In general, the design of the complexes under discussion is determined by the total area of \u200b\u200bthe facility under consideration, the condition and nature of the materials located on the territory, as well as the category of fire and explosion hazard, the presence of maintenance personnel.

After-sales service of fire extinguishing installations is a complex of certain works that are carried out with a set frequency and ensure a long, trouble-free operation of communications, a significant reduction in energy resource costs.

Water extinguishing service

The localization and complete extinguishing of fires using water is to this day the most popular technique. At the same time, complexes that use water are most complex and require constant, enhanced monitoring. Therefore, we consider in more detail the maintenance of the sprinkler and just a water system.

Standard instructions and a list of services for such a complex, as a rule, include about 20 points. It all starts from an external inspection of the parts and ends with complex tests.

The whole mechanism is required to function autonomously. Of course, it is impossible to completely isolate it from other utilities. Therefore, you should have a backup additional element for the water supply (or reservoir with water), an electric power source and a pump.

The main difficulty of the service is not only to maintain the functionality of all elements of the system, but also to establish good and constant communication between them. For example, switching on should be accompanied by an alarm, and a pressure drop - by switching on an additional pump.

It is enough to consider the internal fire water supply of a residential storey buildingwhich must be present by law. It is known that the device of such a water supply system is approximately comparable in complexity to a household water supply device. Indeed, in the house often there are various difficulties with water supply, such as insufficient pressure, malfunctioning taps or primary leaks. Exactly the same problems can arise with fire water supply. The difference is that the consequences are a real danger to the residents of the house.

Therefore, the discussed water supply is often duplicated by an automated system. It goes without saying that the maintenance of fire extinguishing installations is much more complicated and requires professional skills. For example, deluge complexes receive a signal from motive systems or external sensors. Such a system requires periodic verification of the reliability of communication between the drencher and the sensor. In turn, the sprinkler mechanism is a heat-sensitive device that collapses when exposed to high temperature, and requires constant appropriate care.

As you can see, the described modern systems are quite difficult to operate and maintain. But at the same time, it is they who can save human lives, health, or material values \u200b\u200bin a fire.

Maintenance of fire extinguishing systems is the next important step after the design and installation of fire extinguishing systems.

Maintenance of automatic fire extinguishing systems is a set of measures that ensures functioning and serviceability automatic installations fire extinguishing (AUP), smoke protection (PDZ), fire warning systems (CO), fire alarm systems (ATP).

Maintenance of fire extinguishing installations is carried out by periodic preventive inspection of the condition and repair of malfunctions, on the basis of operational documents and typical technological maintenance instructions. Timely and high-quality fire extinguishing service is a guarantee of good operation and a long service life. Regular maintenance of automatic fire extinguishing systems allows you to identify errors in the operation of the equipment, correct them and, therefore, avoid the need for a serious expensive repair of the fire extinguishing system in the event of a breakdown of the entire system.

System specialists carry out the design, installation, commissioning, repair of fire fighting and further maintenance of fire fighting systems. The rich experience of our specialists guarantees a high level of technical and design work. The Sistema group of companies has valid licenses and certificates confirming the right to design, install and maintain fire extinguishing systems. You can familiarize yourself with the documents on our website.

Contact a specialist

Periodic maintenance of fire extinguishing systems

Maintenance of fire extinguishing systems consists of several types of work:

- External inspection is an assessment of the technical condition (how efficient and serviceable the equipment is) with the help of the sensory organs and, if necessary, with the help of control devices (the nomenclature is established by the relevant documents). Specialists determine the technical condition of the plants according to external characteristics.

- A performance check is an assessment of the technical condition by monitoring the installation as a whole and the technical means of their inherent functions.

- Preventive work - this is a preventive action that serves to maintain the operability of installations. Preventive work will include cleaning the external surfaces of technical equipment, lapping, lubricating, soldering, checking the technical condition of internal surfaces, replacing or restoring elements of technical equipment that have failed.

External control and performance checks are carried out at least once a month. The frequency of preventive maintenance is determined individually.

Fire fighting maintenance process

- Coordination, contract, monthly maintenance schedule.

- External inspection of system components (the technological part - pipelines, sprinklers, shutoff valves, cylinders with fire extinguishing agent and compressed air, pressure gauges, switchgears, etc .; Electrical part - electrical cabinets, compressor, etc .; signaling part - control panels, alarm loop, detectors, sirens, etc.); the absence of mechanical damage, dirt, fastening strength, the presence of seals, etc.

- Check valves, pressure in the induction network, etc.

- Control of primary and backup power sources

- Extinguishing agent quality control

- Checking the operability of the components of the system (technological part, electrical part and signaling part)

- Maintenance work

- Checking system performance in manual (local, remote) and automatic modes

- Preparation of technical documentation (Maintenance Journal)

Our facilities

Social insurance fund

Data Center STEK Kazan

Frequency of maintenance of fire extinguishing systems

1. Visual inspection of system components.

In the process of visual inspection check:

- technological part (pipelines, manometers, gate valves, air tank, pumps, dosing devices);

- electrical part (switching and electrical control cabinets, electric drives);

- alarm part (central device with control panel, alarm and control units, buttons);

System components must be clean and free from corrosion. Mechanical damage and leakage are not permitted. Experts check the reliability of fastening and contacts. Visual inspection is carried out every 2 weeks.

2. Control of pressure, water level and operating position of shutoff valves is carried out every 2 weeks.

3. Checking the main and spare power sources and monitoring the automatic switching of power from the working input to the spare input and vice versa, as well as the performance and battery charge are carried out monthly.

4. Control of the correct operation of the component parts of the system (technological, electrical and alarm parts) individually and in the complex is carried out every month.

5. Checking the operation of the system in manual mode (local and remote), as well as in automatic mode, is carried out once every six months.

6. A comprehensive check of the operation of electrical control by the engineering systems of the facility when a fire occurs is carried out once every six months.

7. Once a year is carried out:

- metrological verification of instrumentation;

- flushing pipelines;

- measurement of resistance readings of protective and working grounding;

- fluid replacement in the system and tanks.

8. Once every 3 years, the readings of the insulation resistance of electrical circuits are measured.

9. Rechargeable batteries of spare power supplies are completely replaced every 5 years.

10. Testing of pipelines for strength and tightness (hydraulic and pneumatic) is carried out every 3.5 years

Sistema group of companies provides maintenance of the following fire extinguishing systems

- Water extinguishing systems. They are used at such facilities: shopping centers, office buildings, hospitals, hotels, storage facilities.

- Gas extinguishing systems. They are used for premises with valuable property: computer rooms, banks, objects of art and culture, archives, specialized production and industrial facilities.

- Foam extinguishing systems. They are used at a wide variety of objects: office premises, warehouses, administrative buildings, shopping centers, manufacturing enterprises.

- Powder fire extinguishing systems. They are used in the following rooms: archives, equipment rooms, libraries, museums.

- Sprinkler fire extinguishing systems. They are used at such facilities: hotels, shopping centers, residential buildings, office buildings.

Water extinguishing is a traditional method of fighting fire. Other types of fire suppression also have a lot of advantages, but they can not always be applied. For example, when extinguishing a fire in a room with people, you should not use gas or powder, as these substances can harm their health.

Combating fire with water is a safe, effective, affordable and cost-effective method. It is used to protect office buildings, public institutions, banks, sports fields, office premises, hotels and enterprises for various purposes.

Water extinguishing is carried out by means of deluge or sprinkler automatic systems or manual installations that do not lose their relevance.

The main components of water fire extinguishing systems are:

- pumping station;

- pipelines (distribution, suction, pressure);

- sprinklers;

- controls

- tank with compressor;

- devices for measuring the pressure of water in the cylinder;

- water tank.

Such installations have a rather complicated design, therefore, maintenance of all their units should be regular.

Water extinguishing maintenance

The condition of the process equipment of the water extinguishing installation must be recorded in a special journal, which can only be kept by the responsible person.

Checking the operating status and effectiveness of all nodes and devices of the system is carried out during its full audit (1 time in 3 years). In the process of these works, all the components of the installation are examined, and pressure testing of the pressure pipe and flushing with pressure testing of distribution pipelines are also carried out.

Testing of the water extinguishing system is also carried out once every three years. In this case, a special program is applied, including the actual start-up of the installation without stopping the main work. During the tests, it is necessary to control the water pressure and the intensity of the water supply at the first and last sprinklers.

Our company’s services are not limited to general audits of water extinguishing installations. We are on top level we will carry out maintenance and repair of all components and parts of the system.

The range of work of our company’s specialists also includes:

- Daily check of the water level in the tank with the obligatory marking of the registration log. If the amount of water has decreased, we will identify the leak and quickly repair the tank.

- Quarterly monitoring of the condition of water pipes, valves, measuring instruments and a well. With the approach of cold weather, we will heat the water well to avoid freezing of the liquid.

- Monthly inspection of the pumping station with the mandatory removal of dirt and dust from all surfaces of its elements. Inspection of the system includes the quality of tightening of the seals, the level of lubricant in the bearings, the reliability of all the connecting and fastening elements.

Moreover, 2 times a month, all fire pumps must be put into operation with registration of the generated pressure. If the desired parameter value is not provided, our experts will determine the cause of the problem and eliminate it as soon as possible.

Repair and replacement of worn parts is carried out as needed.

- Once every three years - inspection of all engines and pumps with the correction of existing problems.

- Monthly check of the status of controls, valves, valves and check valvesPressure control at all stages. Defects must be repaired immediately.

- Once every three months - inspection of pipelines, in which we note:

- absence or presence of leaks and deflections; level of tightening fasteners; condition of paint on surfaces; necessary distance between electric cables and pipes.

- Monthly monitoring of work and the amount of pollution on irrigators. Rust or dust on these devices must be removed immediately.

- Daily inspection of the air tank, checking the water level and air pressure. If necessary, we pump air to the desired level.

- Annual check of all system pressure gauges.

Once a week, specialists will start the compressor at idle.

A full revision of the air tank is carried out annually. At the same time, such events are held:

- draining and inspecting the tank, removing contaminants;

- safety valve check;

- inspection of painted surfaces for coating defects;

- compressor status monitoring with replacement of defective parts;

- other jobs.

Air tank pressure gauges are inspected monthly, and pipeline - once every six months.

Our company is a group of highly skilled professionals who know and love their work. Turning to us for the constant maintenance of water extinguishing systems, you get an affordable and quality service.