Check valve 2110 injector. The problem of a long start after downtime (solved)

The vehicle’s power system is designed to store fuel, clean fuel and air from impurities, supply air and fuel to the engine cylinders. The power supply system consists of a fuel tank, a fuel module, a fuel filter, a fuel rail with nozzles, an air filter, fuel pipes, air ducts, a throttle assembly, an intake module, and a gas vapor recovery system.

The air entering the engine cylinders is cleaned of dust by an air filter. Air filter installed in the engine compartment on three rubber mounts. The filtering filter element is replaceable, made of special paper. In order to prevent the inflow of contaminated air into the intake duct, there is a sealing rim at the top of the element. To replace the filter element, the filter cover is removable. The purified air through the mass air flow sensor (for more details, see 8.4) passes through the air duct to the throttle valve.

A throttle valve controls the amount of air entering the engine cylinders. The damper drive from the gas pedal is cable. The damper rotates on an axis in the housing (pipe). The throttle body is mounted on the inlet module flange with studs.

Throttle Node: 1 -

throttle drive sector; 2, 4 - fittings for connecting to the engine cooling system; 3 - fitting exhaust gases; 5 - throttle position sensor; 6 - regulator idle move; 7 - fitting for connection with an adsorber; 8 - throttle; 9 - throttle body pipeA channel for coolant is made in the housing. With rubber hoses, the channel is connected to the cooling system. The circulation of the coolant through the throttle body prevents freezing of the internal air cavities of the body in winter. Fittings for connecting to the adsorber and crankcase ventilation system are installed in the housing.

The throttle body, with the throttle position sensor and idle control installed on it (for more details, see 8.4), form throttle assembly.

The fuel reserve is stored in a 43 liter tank. Fuel tank steel, welded from two stamped parts. The tank is suspended from the bottom of the car on two steel clamps. The filler neck of the fuel tank is brought to the starboard side of the car and is closed by a stopper. Fuel from the tank is supplied by electric fuel pump submersible type.

The pump is installed in the fuel tank. To access the pump at the bottom of the car under the rear seat cushions, a hatch with a cover is made.

A strainer is installed at the inlet of the fuel pump, which traps small solid particles of debris that have fallen into the fuel tank with gasoline. The pump is energized by the command of the computer (see 8.4) when the ignition is turned on. If at the same time an attempt is not made to start the engine, then after 2-3 seconds the computer will turn off the fuel pump.

Fuel pump:

1 - protrusion for attaching the strainer; 2 - fuel intake pipe for connecting a strainer; 3 - case; 4 - block connector; 5 - output (discharge) pipe for connecting with the cover of the fuel module with a corrugated tubeComment:

On a car with an MP7.0-type model ECU, the first attempt to start the engine after connecting the battery can turn on the fuel pump only at the same time as the starter. In the future, the fuel pump will work as on vehicles with other types of ECUs. However, after three consecutive ignition starts without starting the engine, the fuel pump will only be turned on simultaneously with the starter.

From the pump through the corrugated tube of the fuel module (see below), gas enters the fuel line and then into the fuel filter, where the fuel is subjected to more thorough cleaning.

Fuel filter - paper, installed in a metal non-separable case.

The cleaned fuel enters the fuel rail through the fuel line.

Fuel filter for engine 21124 (1.6i):

1 - inlet pipe; 2 - case; 3 - arrow of the direction of fuel flow (painted with paint on the filter housing); 4 - outlet pipeComment:

The 2112 (1.5i) engine fuel filter has threaded connecting pipes.

The fuel rail holds the four nozzles and brings fuel to them. The ramp to nozzle connection is sealed with rubber rings. The ramp is bolted to the cylinder head.

The fuel pressure regulator is a bypass valve that maintains in the system (fuel line) an operating pressure of 284-325 kPa for the 2112 engine or 378-390 kPa for the 21124 engine, which is necessary for the correct operation of the injection system (for more details, see 8.4).

In accordance with the environmental requirements of EURO II, the car is equipped fuel vapor recovery system, the fuel space of the tank is not directly connected with the atmosphere, but through the elements of this system.

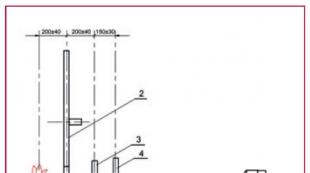

Location of the separator on a car with an engine 21124 (1.6i):

1 - separator; 2 - separator mounting bracket; 3 - gravity valve

Comment:

On a car with an engine 2112 a safety valve is additionally installed here. On a car with an engine 21124, a safety valve is made in the filler cap.

Adsorber:

1 - adsorber body; 2 pipe for connecting the inner cavity of the adsorber with the atmosphere; 3 - purge valve adsorber; 4 - connecting pipe of the valve; 5 - connecting pipe adsorberThe system consists of a separator, a gravity valve adsorber, an adsorber purge valve, a check valve, connecting tubes and hoses. The separator and gravity valve are fixed under the left rear wing of the car. In the separator, gasoline vapors are partially condensed and returned back to the fuel tank. The gravity valve prevents fuel from escaping from the tank when the vehicle is turned over.

From the separator, non-condensing vapors of gasoline pass through tubes and connecting hoses to an adsorber, which prevents vapors from entering the atmosphere. An adsorber is a container where gasoline vapors are absorbed by activated carbon. When the engine is running at a high crankshaft speed, the computer sends a signal to open the canister purge valve, and gasoline vapor is sucked into the receiver of the intake module.

Features of the engine power system 2112 (1.5i)

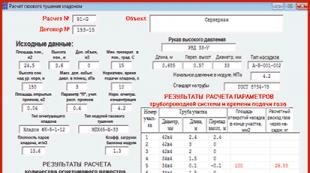

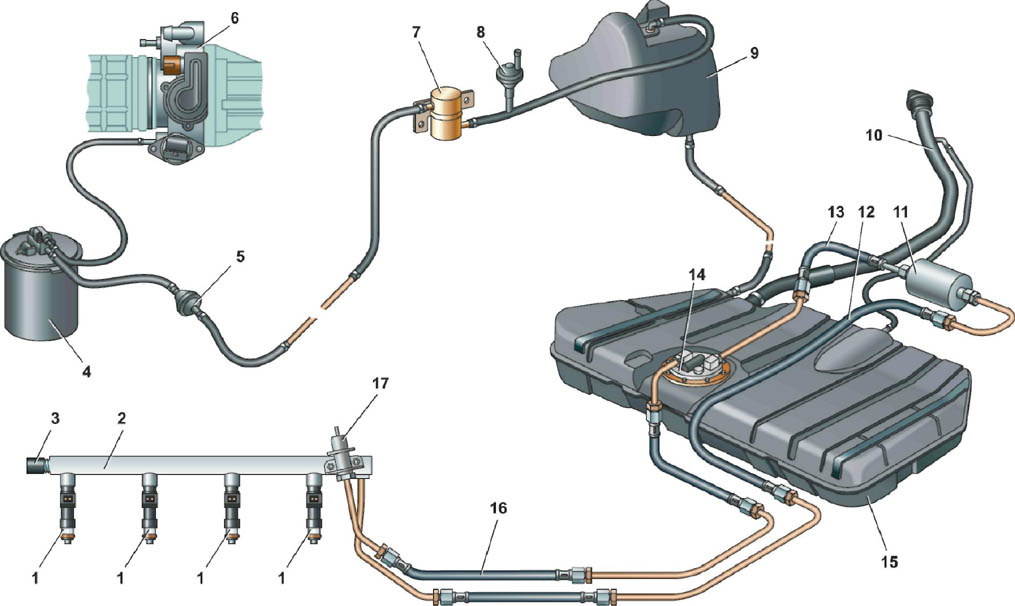

Scheme of the engine power system 2112 (1,5i):

1 - nozzles; 2 - a fuel rail; 3 - diagnostic fitting of the fuel rail (for checking the fuel pressure, closed with a threaded cap); 4 - adsorber; 5 - check valve; 6 - throttle assembly; 7 - gravity valve; 8 - safety valve; 9 - separator; 10 - a jellied pipe; 11 - fuel filter; 12 - fuel supply line; 13 - a fuel pipe hose connecting the outlet pipe of the fuel module to the fuel filter; 14 - fuel module; 15 - a fuel tank; 16 - drain fuel line; 17 - fuel pressure regulator

Air to the intake valves of the 2112 (1.5i) engine cylinders receiver and intake manifold. These elements of the intake tract are interconnected by rubber couplings.

The fuel pump is combined with a fuel gauge sensor in a single unit - fuel module (often called - gasoline pump). A pressure pump delivers fuel from the tank through the fuel filter to the fuel rail.

Fuel pressure regulator installed on the fuel rail. Excess the amount of fuel is returned to the tank through the drain fuel line.

2112 Fuel Engine Module (1.5i)

: 1 - fuel gauge sender; 2 - connecting block; 3 - inlet pipe; 4 - output (discharge) pipe; 5 module cover; 6 - guide cover module; 7 - electric gasoline pump in a plastic casing; 8 - intake chamber

2112 (1.5i) engine fuel rail assembly with nozzles: 1-

fuel supply pipe to the fuel rail; 2 - fuel pipe to drain the fuel into the tank; 3, 4, 5 and 6 - nozzles; 7 - diagnostic fitting (for checking fuel pressure, closed with a threaded cap); 8 - a fuel rail; 9 - fuel pressure regulator;

Features of the engine power system 21124 (1.6i)

Location of engine power system elements

[Engine with plastic trim removed.] 21124 (1.6i) in the engine compartment: 1 - inlet module; 2 - throttle assembly; 3 - a hose of an air supply to a butterfly valve; 4 - air intake; 5 - air filter; 6 - a fuel rail; 7 - throttle cable; 8 - the union of the fuel rail; 9 - check valve adsorber; 10 - adsorber

Engine intake module 21124 (1.6i):

1 - flange with a sealing ring for mounting the throttle pipe; 2- receiver; 3- inlet pipe flange with o-rings for connecting to the cylinder head

Scheme of the engine power system 21124 (1.6i):

1 - nozzles; 2 - a fuel rail; 3 - diagnostic fitting of the fuel rail (for checking the fuel pressure, closed with a threaded cap); 4 - adsorber; 5 - check valve; 6 - throttle assembly; 7 - gravity valve; 8 - separator; 9 - a fuel pipe connecting the fuel filter with a tee; 10 - fuel pipe connecting the fuel filter with the outlet pipe of the fuel module; 11 - fuel module; 12 - fuel filter; 13 - a jellied pipe; 14 - a fuel tank; 15 - a hose connecting the fuel filter and the fuel module with the fuel line; 16, 18 - metal pipes of the fuel line; 17 - a connecting hose; 19 - fitting for connecting the fuel rail to the fuel lineAir is supplied to the inlet valves of the engine cylinders through the inlet module.

The intake module of the engine 21124 is made of special plastic and is a non-separable element.

21124 (1.6i) engine fuel module:

1 - inlet pipe (for supplying fuel to the pressure regulator); 2 output (discharge) pipe; 3 module cover; 4- fuel gauge; 5- intake chamber; 6 - guide cover moduleThe filler cap has two valves: one for emergency pressure relief of fuel vapor from the tank (which is possible with increasing ambient temperature), and the other for air from the atmosphere when fuel is consumed from the tank (this eliminates the occurrence of a strong vacuum in the tank).

The fuel pump is combined with a fuel gauge and fuel pressure regulator in a single unit - fuel module (often called - gasoline pump).

21124 (1.6i) Engine Fuel Pressure Regulator: 1-

a hole for dumping excess fuel; 2, 4 - sealing rings; 3- holes for supplying fuel to the regulator; 5- case; 6 - output for connecting the regulator to groundOn a car with an engine 21124 (1.6i), fuel from the pump (through the outlet pipe of the fuel module) enters the fuel filter. The refined gasoline is again fed through the fuel line and through the tee to the inlet pipe of the fuel module and then fed to the fuel rail. Excess fuel is vented through the pressure regulator into the tank. The fuel pressure regulator is installed in the fuel module cap.

21124 (1.6i) engine fuel rail assembly with nozzles:

1 - fitting for connecting to the fuel line; 2- fuel rail; 3 - diagnostic fitting (for checking operating pressure, closed with a threaded cap); 4, 5, 6 and 7 nozzlesThe idea was not invented by me, so you don’t need to kick me with my feet. This refinement spied on this person andRiU

After the car spends the night on the street, or will stop for about two days. The car starts up poorly in the morning, only from the second, third time. You have to manually pump the gas pump, or for a long time to twist the starter. But after a successful morning start during the day, the start is excellent. The reason may be either the incorrect setting of the angle of advance of the injection, or the airing of the system as a result of the outflow (decrease, runoff) of the fuel. To solve the problem with the outflow of fuel and thereby help the car at startup, it is necessary to install the fuel line between the gas pump and the carburetor in the fuel line

Fuel check valve VAZ 2108. Attention! The check valve must be installed with the arrow in the direction of the carburetor.

That's how my design looks like

Fuel check valve VAZ 2108

Example. Correct check valve with different flow rate

Note. It is advisable to use the valve from the VAZ 2121, or from the VAZ 2110 they are more reliable according to the reviews of people, but in general it would not be bad to put a metal one with a higher throughput, damn it, but as they say, a good idea comes after))

As a result, the car starts easier. We’ll travel, see how this stray will behave, but there is a suspicion that even the valve will evaporate fuel (gasoline), well, this is the peculiarity of these Ozone carburetors. If such a picture is confirmed, then we will return everything to its place, as it was.

Price tag: 45 UAH

On VAZ-2110 vehicles, the fuel pressure regulator ensures the functioning of the fuel injection system in normal mode. With its help, the optimum pressure value necessary for the gasoline to be in a fog state is maintained in the fuel rail. Due to the pressure that is above atmospheric, the air-fuel mixture is injected into the combustion chambers. If the regulator fails, then the entire injection system does not work correctly and serious problems in the functioning of the engine are possible.

How regulators work

A fuel rail is required to mix gasoline vapor and clean air. It maintains a pressure of 2.9-3.3 kgf / sq. cm due to pressure regulator. For injection nozzles with a solenoid valve are used. A regulator is connected to them, which is a valve made of a membrane. The input of the device is from the side of the ramp, the output is to the fuel drain line. A tube from the intake manifold is connected to the fuel pressure regulator VAZ-2110.

The pressure is adjusted by means of a spring, its rigidity is selected so that it is compressed only with a certain force. If the pressure fuel mixture in the ramp exceeds 3.3 kgf / sq. cm, then the spring is compressed, the valve opens and the excess is ejected into the return line. Upon reaching a pressure of 2.9 kgf / sq. see valve closes.

Types of malfunctions

Among the most frequent failures of the device are the following:

- The valve does not hold pressure - gasoline circulates freely throughout the entire line, including the return line. In this case, the pressure in the ramp decreases significantly, and it can be unstable. When you increase the engine speed, it starts to stall - there is not enough pressure to carry out a normal injection. The amount of gasoline inside the ramp is very small. There is a noticeable decrease in power, the time it takes to start the engine is longer than during normal operation. The gasoline pump will run longer than usual.

- The valve does not work at all (it does not open at maximum pressure) - the excess does not go into the tank. In the fuel rail, the pressure is too high, there is a significant excessive consumption of gasoline, it fills the cylinders. Such a malfunction of the fuel pressure regulator on the VAZ-2110 is not resolved, so you only need to change the device completely.

Signs of breakage

To independently detect a breakdown of the device, take a look at the engine. Typically, a malfunction gives itself out like this:

- The engine is unstable, it shakes, there are gaps in the cylinders.

- When idling, the motor stalls.

- Acceleration is weak - low throttle response, driving is difficult.

- A noticeable decrease in engine power, even with minimal load, one feels how “hard” it is.

- The rotation of the crankshaft is either with a lower frequency or with an increased one. Sometimes the rotation speed varies over a wide range.

- A significant increase in gas mileage.

- Jerks and dips with uniform movement.

- Sometimes breakdown is manifested by a difficult start of the motor.

- Among the signs of malfunction of the fuel pressure regulator on the VAZ-2110, one can single out a significant excess of the content of CH and CO in the exhaust.

The last failure is detected only during engine diagnostics using a gas analyzer.

Regulator Diagnostics

For diagnostics you will need the following tool:

- manometer (the one that is used to check tire pressure is suitable);

- open end wrench at 24;

- hexagons (only No. 5 is required).

And now about how to check the fuel pressure regulator on the VAZ-2110:

- Remove the plug from the fitting, which is located at the end of the fuel rail.

- The spool from the fitting can be turned out using a cap (metal) for tire wheels.

- Using a suitable diameter hose, connect a pressure gauge to this fitting. The edges must be fixed with clamps - high pressure inside, can disrupt.

- Start the engine and measure the pressure.

- Disconnect the vacuum tube from the regulator and repeat the measurement.

When the vacuum tube is turned off, an increase in pressure of 0.2-0.7 kgf / sq. see. If this did not happen, a complete replacement of the device is required.

How to replace the regulator?

To replace the regulator, you will need to perform the following steps:

- Stop engine. Do not perform any actions on a running motor.

- Relieve pressure in the ramp. Just unscrew the spool from the fitting and wait until the pressure is equalized.

- Unscrew the nut that attaches to the fuel pressure regulator on the VAZ-2110 return pipe.

- Remove the bolts securing the instrument housing to the fuel rail.

- Remove the regulator fitting from the hole.

- Disconnect the handset from the body.

- Remove the regulator completely.

All steps for installing a new device occur in the reverse order. Be sure to wet everything in gasoline before installation. All rubber elements that are damaged or have lost their original appearance must be replaced with new ones. Poor gaskets and seals will cause the entire fuel supply system to malfunction.

The power supply system of the injection engine VAZ 2110, VAZ 2111, VAZ 2112, Lada Ten

Scheme of fuel supply of the engine with fuel injection system

1 - nozzles

2 - fitting plug for fuel pressure control

3 - injector ramp

4 - an arm of fastening of fuel tubes

5 - fuel pressure regulator

6 - adsorber with a solenoid valve

7 - hose for suction of gasoline vapor from the adsorber

8 - throttle assembly

9 - two-way valve

10 - gravity valve

11 - safety valve

12 - separator

13 - a separator hose

14 - a stopper of a fuel tank

15 - bulk pipe

16 - a hose of a bulk pipe

17 - fuel filter

18 - fuel tank

19 - electric gasoline pump

20 - drain fuel line

21 - fuel supply pipe

Fuel is supplied from a tank installed under the bottom in the rear seat area. The fuel tank of the VAZ 2111 - steel, consists of two stamped halves welded together. The filler neck is connected to the tank with a rubber gas-resistant hose secured with clamps. The cork is tight. Gasoline pump - electric, submersible, rotary, two-stage, installed in the fuel tank. Developed pressure - not less than 3 bar (3 atm).

The VAZ 2110 gasoline pump turns on at the command of the injection system controller (with the ignition on, the VAZ 2112) through the relay. To access the pump under the rear seat in the underbody of the car there is a hatch. From the pump through a flexible hose, fuel is supplied under pressure to a fine filter and then through steel fuel lines and rubber hoses to the fuel rail.

The fuel fine filter - non-separable, in a steel case, with a paper filter element. An arrow is marked on the filter housing, which should coincide with the direction of fuel movement.

The fuel rail serves to supply fuel to the nozzles and is mounted on the intake manifold. On the one hand, there is a fitting on it to control the fuel pressure, on the other, a pressure regulator. The latter changes the pressure in the fuel rail - from 2.8 to 3.2 bar (2.8-3.2 atm) - depending on the vacuum in the receiver, maintaining a constant differential between them. This is necessary for accurate fuel metering with nozzles.

The fuel pressure regulator VAZ 2111, VAZ 2112 is a fuel valve connected to a spring-loaded diaphragm. Under the action of the spring, the valve is closed. The diaphragm divides the regulator cavity into two isolated chambers - “fuel” and “air”. The “air” is connected by a vacuum hose to the receiver, and the “fuel” - directly with the ramp cavity. When the engine is running, the vacuum, overcoming the resistance of the spring, tends to retract the diaphragm, opening the valve. On the other hand, fuel presses on the diaphragm, also compressing the spring. As a result, the valve opens, and part of the fuel is vented through the drain pipe back into the tank. When you press the "gas" pedal, the vacuum behind the throttle valve decreases, the diaphragm closes the valve under the action of the spring - the fuel pressure increases. If the throttle valve is closed, the vacuum behind it is maximum, the diaphragm pulls the valve harder - the fuel pressure decreases. The pressure drop is set by the stiffness of the spring and the size of the valve bore, not subject to adjustment. The pressure regulator is non-separable, when it fails, it is replaced.

Nozzles are attached to the ramp through rubber o-rings. The nozzle is an electromagnetic valve that transmits fuel when voltage is applied to it, and locks under the action of a return spring when it is de-energized. At the outlet of the nozzle there is a spray through which fuel is injected into the intake manifold. The injectors are controlled by the injection system controller. If the nozzle winding is open or shorted, it should be replaced. If nozzles become clogged, they can be washed without dismantling at the special service station stand.

The feedback injection system uses a VAZ 2110 fuel vapor recovery system. It consists of an adsorber installed in the engine compartment, a separator, valves and connecting hoses. The fuel vapor from the tank is partially condensed in the separator, the condensate is drained back into the tank. The remaining pairs pass through the gravity and two-way valves. The gravity valve prevents the leakage of fuel from the tank when the VAZ 2111 is toppled over, and the two-way valve prevents excessive pressure increase or decrease in the fuel tank.

Then the fuel vapor enters the adsorber vaz 2110, where it is absorbed by activated carbon. The second adsorber fitting is connected by a hose to the throttle assembly, and the third is connected to the atmosphere. However, when the engine is off, the third fitting is blocked by an electromagnetic valve, so that in this case the adsorber does not communicate with the atmosphere. When the engine starts, the injection controller starts to supply control pulses to the valve with a frequency of 16 Hz. The valve communicates the adsorber cavity with the atmosphere and the sorbent is purged: gasoline vapors are sucked out through the hose to the receiver. The greater the air consumption of the engine, the longer the duration of the control pulses and the more intense the purge.

In a feedback-free injection system, the fuel vapor recovery system consists of a separator with a two-way check valve. The air filter VAZ 2111 is installed in the front left part of the engine compartment on three rubber holders (supports). The filter element is paper, when installing its corrugations should be parallel to the axis of the car. After the filter, air passes through the mass air flow sensor and enters the inlet hose leading to the throttle assembly. The throttle assembly is mounted on the receiver. By pressing the "gas" pedal, the driver opens the throttle, changing the amount of air entering the engine, and hence the combustible mixture - because the fuel supply is calculated by the controller depending on the air flow. When the engine is idling and the throttle is closed, air enters through the idle speed control - a valve controlled by the controller. The latter, by changing the amount of air supplied, maintains the set idle speed (in the computer program). The idle regulator VAZ 2112 is non-separable, when it fails, it is replaced.

http://www.vazclub.com

Fuel systems of automobile engines is a rather complicated device, which is contraindicated without knowledge of certain basic concepts. Knowledge of materiel and minimal experience are the main components that will help to defeat any malfunction. In a snap, even a wheel cannot be dismantled. Training is needed. And the fuel system is a complex set of devices that seem elementary only at first glance.

Even the usual power system of an old VAZ 2101 can throw such a focus that modern technological engines could not even dream of, not to mention the diesel engines of the last years of production, where for every centimeter of the fuel line there are two electronic sensors. Such a trifle as a non-return valve can also cause a stupor by an experienced mechanic, but if an average motorist speaks about an non-return valve, then it’s worthwhile to understand this in more detail.

Fuel system check valve

Any non-return valve in any hydraulic system serves to ensure that the fluid flows along the line in only one direction. This may be necessary in many cases, but with reference to the fuel system, a non-return valve prevents the drain of unused fuel from the fuel line to the tank. For various reasons, but the essence is this. This applies to gasoline engines with a carburetor, injection enginesand diesel engine power systems.

Check Valve Video

Structurally, most often the check valve is extremely simple - it is a ball valve with a precisely calibrated soft metal seat. The valve allows the fuel to flow unhindered in one direction, while the fuel cannot flow back into the tank, locking the valve with its own pressure. An elementary device, nothing complicated, but sometimes its malfunction or banal absence leads to serious malfunctions. The reverse is often confused, and these are completely different things. In diesel and injection engines, where pressure is required for the operation of the power supply system, the pressure reducing valve is responsible for the stable pressure; nevertheless, it works in conjunction with a non-return valve. It is logical to solve all problems as they become available, which is why we will do this.

Where is the check valve

You need to know the enemy by sight, so let's start by looking for a check valve in the car’s power systems. The valve can be installed in the casing of the fuel pump of injection engines, on the fuel rail and simply in the fuel line between the gas tank and the fuel injectors. On diesels, it is installed between the low-pressure hand pump and the high-pressure fuel pump so that the pressure at the inlet to the high-pressure pump is always stable. Such a system is installed on all KAMAZ 740, Tatra, MAN and Renault Magnum engines. In diesel engines with a fuel preheating system, a non-return valve is mandatory installed in front of the heating system, as in Magirus trucks, the same Arctic KAMAZ trucks, and many others.

In domestic cars with injectors, a 16-valve VAZ 2110, 2114, a non-return valve is installed in the gas pump and on the fuel rail, by analogy with a diesel system. In old carburetor cars, VAZ 2108, 2109, classic rear-wheel drive models, the role of the non-return valve is played by the gas pump itself, which is mounted on the cylinder block and does not pass fuel back into the tank, thanks to the airtight exhaust valve of the gas pump. When the valve loses its tightness, gasoline goes completely into the tank, and engine start is possible only with manual pumping.

Prudent owners independently installed check valves to facilitate starting the motor. On older models of Opel Kadet, Mazda 323, with a difficult start, it was enough to buy and insert a non-return valve into the power system closer to the carburetor or mono injector, as the fuel ceased to merge along the main line into the tank, and the start became normal even at subzero temperatures.

What to expect from a non-working check valve

Nothing good. At least this is a difficult start. Airing the diesel power system is a pretty problematic breakdown on the road. Injection power systems also do not like air in the system. Troubles begin when we turn off the engine, and the fuel, which should wait for the next start (the system must maintain working pressure), goes into the tank along the working line, and air takes its place. Now, to start the engine, it is necessary to normalize the pressure in the system and supply fuel to the nozzles. To do this, you need to turn the motor with a starter for 40-50 seconds, so there can be no talk about starting from a half-turn.

Unclear situations also arise when they confuse a non-return valve with a pressure regulator, which is installed on the fuel rail for most injection engines - 2110, 2114, Kia Sportage 3.

His job is to equalize the pressure on the fuel rail section, otherwise the nozzle simply will not receive fuel at the right pressure, and will not be able to feed it into the combustion chamber. At that moment, when we turn off the ignition, the regulator stops the fuel supply to the nozzles, the locking mechanism is activated, thus part of the fuel line is cut off from the gas pump with a non-return valve to the fuel rail. And now only the check valve is responsible for the presence of fuel in the system. And to check who is to blame for this situation is simple. If the pressure in the fuel rail is normal, and in most cars it should be within 2-3 atm, then the non-return valve is to blame.

As you can see, one tiny valve can do such things. This once again confirms that there are no trifles in the car device and cannot be, and each breakdown is eliminated first with the head, and only then with the hands.

- news

- Workshop

Princess Diana convertible will be auctioned off

The price of a car that was released on March 7, 1994, and covered 21,412 miles (34,459 km), is estimated at 50,000 - 60,000 pounds (approximately 55,500 - 66,600 euros). Audi Cabriolet was an open version of the Audi 80 model. The machine is green, ...

Traffic jams want to win by paid entry into the cities

One of the paragraphs of the new document says that the authorities will be able to impose temporary restrictions on traffic with the help of "charging for traffic on the roads," reports TASS. It is assumed that the fare will be set by higher executive bodies authorities of constituent entities of the Russian Federation and local authorities. The fee will depend on certain types and categories of vehicles, ...

Authorities told how much gasoline will cost in 2017

New calculations on the withdrawal of funds from oil companies were prepared following a tax meeting led by Deputy Prime Minister Arkady Dvorkovich. They contain not only data on the estimated increase in budget revenues, but also information on a possible change in fuel prices, RBC reports. According to existing plans, in 2017 it is planned to attract ...

Sobyanin about storm sewer in Moscow. Quote of the Day

This was announced by Sergei Sobyanin on the radio station “Moscow Says”. P.S. - Recall that on August 15, 2016 in Moscow, because of heavy rains, once again there was a massive flooding of the streets, which caused a corresponding reaction of the townspeople. Source: auto.mail.ru Travel on the toll road Moscow - St. Petersburg (Route M-11): scheme, map, fare. ...

The Russian woman, on whose car the wall of the house fell, was refused compensation

Now a woman who has parked according to the rules not far from the construction site will have to go to court, reports m24.ru with reference to the Moscow 24 television channel. The incident occurred in December 2015 in Moscow on Karamyshevskaya embankment. The builders dismantled the old building and the workers probably did not notice a car worth about 2 million rubles. As a result, part of the wall of the old ...

GM legendary designer quits

Over the entire 108-year history of the General Motors concern, the company only six times changed the chief designer, and Ed Welburn - among the most famous. Back in the 60s, 11-year-old Ed wrote a letter to GM asking: how do I become a car designer? The guy received a response from one of the employees, and this turned him over ...

The appearance of the new hatchback Honda Civic is revealed (photo)

Currently, Honda has published a photo of the American version of the Civic, while the European version of the model will be presented at the Paris Motor Show. However, already now the photo shows that the car looks almost the same as the concept presented in March 2016 at the Geneva auto show. In the US, the Honda Civic hatchback will be offered with a 1.5-liter turbo four, ...

Traffic jams in Moscow will be warned in a week

The center’s specialists took such a measure because of work in the center of Moscow under the My Street program, the official portal of the Mayor and the capital’s government reports. The data center already analyzes automobile flows in the Central Administrative District. At the moment, there are difficulties on the roads in the center, including on Tverskaya Street, Boulevard and Garden Ring and New Arbat. In the press service of the department ...

The British revived a sports car 60 years ago

In 1957, the world saw one of the most famous sports cars of the last century - Lotus Seven, developed by the famous English designer Colin Chapman. Soon, the rights to release this sports car passed to the company Caterham, which is currently producing it. Despite the fact that Caterham Seven has quite powerful ...

In Russia, the first camera that fixes the ride on the sidewalk

As soon as the driver is in the camera’s visibility range and enters the pedestrian walkway, he will be automatically fined 2,000 rubles. If the experiment is considered successful, they will put the same cameras in other places, Rossiyskaya Gazeta reports. According to the head of the Moscow Center for Traffic Management (DPC) Vadim ...

Which sedan to choose: Camry, Mazda6, Accord, Malibu or Optima

Which sedan to choose: Camry, Mazda6, Accord, Malibu or Optima

Powerful plot The name "Chevrolet" is the history of the formation of American cars. The name “Malibu” beckons with its beaches, on which numerous films and television series were shot. Nevertheless, from the first minutes in the Chevrolet Malibu car there is a prose of life. Pretty simple appliances ...

The most bought cars in 2016-2017 in RussiaThe most bought cars in 2016-2017 in Russia

How to choose a new car? In addition to taste preferences and technical specifications future car, you can help the list or rating of the best-selling and most popular cars in Russia in 2016-2017. If the car is in demand, then it deserves your attention. The obvious fact is the Russians ...

What cars in 2017-2018 are most often bought in RussiaWhat cars in 2017-2018 are most often bought in Russia

The number of cars on the roads of the Russian Federation is constantly growing - a fact that is confirmed by the annual study of sales of new and supported models. So, based on the results of a study that can answer the question of which cars are bought in Russia, for the first two months of 2017 ...