Gas fire system. We select the best gas fire extinguishing module. Routine maintenance of gas fire extinguishing systems

From 70 rub./m 2

From 3000 rub / m 3

From 3000 rub./month

Application of gas fire fighting in industries

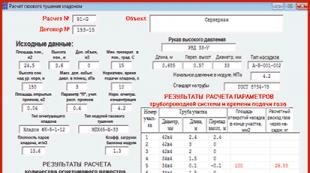

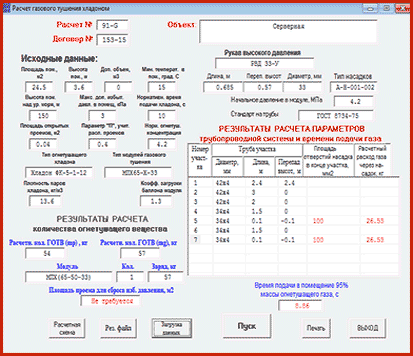

You can get a calculation for a gas fire extinguishing installation by filling out our form, indicating the dimensions of the room and its purpose, and we will send you a calculation within 30 minutes.

Understanding fire extinguishing systems

Alternatively, you can get a free quote for installing or maintaining a fire extinguishing system for your business. There are many systems on the market, and this can make it difficult to make sure that you have made the most effective choice that offers the best protection for your business, employees and customers. We will offer a full range of solutions that are provided throughout the country. Your options are usually divided into two key types: either “Chemical” or “Inert” fire extinguishing systems.

The calculation will include:

- Calculation of the volume of the cylinder with accessories

- Calculation of extinguishing agent (ROTV) in the bottle for the volume of the room

- Pipe fittings

- Auto part

- Design work

- Installation work

- Commissioning works

- Commissioning

To help make informed choices, here are the highlights of each. When discharged, these inert gas systems work to reduce oxygen in a room or other enclosed area from normal air levels from 21% to less than 15%. However, life is stable at this lower level, and healthy people should not suffer from any negative consequences.

The products listed above are all approved for use in areas that are commonly occupied. These extinguishing extinguish mainly physical processes. Their molecules absorb heat, reducing the temperature of the flame to a point below which they cannot propagate, and thus the fire goes out. The products listed by us are also safe for use in normally occupied places, provided that they are in specified concentrations.

Form for calculating the cost of gas fire extinguishing:

Innovation Center Skolkovo

Development of design and working documentation for server-side automatic gas fire extinguishing

Supply of equipment based on extinguishing agent NOVEC 1230

Construction and installation work of gas fire extinguishing

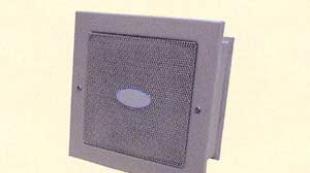

The final and important key point. When using any gas extinguishing system, the key consideration is pressure damping. When an agent is discharged into a confined space, it creates positive pressure. If there is insufficient natural leakage, structural damage may occur due to excessive pressure in this area.

Brief description of the protected object

That is why our experts will always offer a full range of solutions. We calculate the correct size of the pressure relief flap required for each enclosed area. We can also offer both an installation for installing a pressure shock absorber and an exhaust system for fire extinguishing equipment, along with all necessary maintenance work.

BC "Simonov Plaza" for the needs of the company LLC "Urinholt"

Development of design and working documentation for server-side automatic gas fire extinguishing

Supply of equipment based on extinguishing agent Cold 125

Commissioning of gas fire extinguishing server

LCD at Khimki st. Moskovskaya 21

To learn more about our room integrity verification services. The lack of effective fire protection should not become apparent only after the event has occurred - the adoption of effective precautions is important. That is why our team of professionals is ready to offer free consultations, answer any questions and provide a free quote for an effective system. Use our inquiry form or a free quote.

Our customers are businesses, governments, universities, hospitals and museums around the world with valuable assets for protection against fire. Applications range from computer and electronic suites to military vehicles. During discharge, fluid flows through a network of pipelines into a protected area where it evaporates.

Installation of smoke protection (smoke removal system, air intake)

Installation of dispatching complex

Installation of automation of pumping stations of internal fire water supply

Workstation automation

Modular gas fire extinguishing server

With the development of computer technology, most enterprises began to equip server ones. According to the rules of fire safety, they should not occupy an area less than 24 m 2. In addition, the temperature and humidity levels should be constantly monitored in such rooms.

The Kyoto Protocol deals exclusively with emission reductions. The Kyoto Protocol is an attempt by developed countries to find a way to determine the baseline and ultimately reduce emissions of substances that contribute to global warming.

It has been thoroughly tested to meet strict American and international standards. Iceland, which has close ties with Denmark, has taken a similar position. Moreover, these levels do not pose a threat to electronics or other sensitive equipment. There is no such thing as "ordinary combustible fire." Fires are not combustible; they burn.

Since the equipment located in the server rooms has a high cost, and besides, it should not be damaged in any way at the time of an emergency, in such rooms only a gas fire extinguishing system can be used, which you can order from our company.

Thanks to the modules, gas penetrates into the most isolated areas of the server room, which cannot be said about other substances. It does not harm property, and its remains are removed from the building through ventilation channels. In addition, it ensures the proper quality of extinguishing a fire by blocking oxygen.

And it's hard to put a price on safety and peace. Water sprinklers provide effective fire protection for buildings and structures. Water sprinklers are designed to control fires by limiting the spread of fire and keeping it in its original location long enough for professional firefighters to react and extinguish a fire before a building can be completely lost. Unfortunately, water will also destroy computers, electronics, artwork, and more — the things you wanted to protect.

Prices for a gas fire extinguishing system for a server room will depend on the area occupied by the room, the presence of a raised floor and a false ceiling in the room, as well as the amount of equipment needed for installation.

Installation and system features

The cost of gas fire extinguishing for the server depends on the number of modules used in the fire protection system.

It is designed to detect and extinguish fires at the earliest stages to prevent damage or downtime. Extensive tests have shown that water mist systems do not work well in small fires and are best suited to suppress large fires. It is also important to remember that water is electrically conductive and can be extremely harmful to sensitive electronic equipment or valuable assets.

Applications for chemicals that can self-oxidize or generate their own oxygen even without the presence of air, such as gunpowder and cellulose nitrate; or compounds that are very unstable and can spontaneously burn, such as hydrazine and many peroxides. Processing plants or areas using pure, powdery forms of metals. For fires using reactive metals such as lithium, sodium, potassium, magnesium, titanium, zirconium, metal hydrides and radioactive elements of uranium and plutonium, a different extinguishing strategy is required.

The main element is gas cylinders. We use a fire extinguishing agent for these purposes, which includes: Freon 125, Freon 227e, Novec 1230. The modules themselves are made of durable alloy steel, and are coated on the outside with polymer compounds that protect the metal and prevent corrosion from developing.

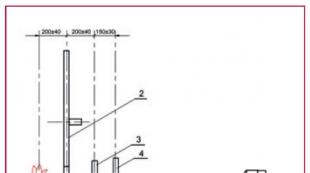

Each cylinder is equipped with a locking and starting device. To extinguish the fire, gas from the cylinder is supplied by means of a distributor to pipelines mounted in the ceiling. Each of them has special nozzles spraying the gas composition.

Section 4-3 requires a six-month verification of agent quantity and cylinder pressure. In general, there is no limit to the height of protection on the lower floor. In fact, if the lower floor were 3 meters high, it would be treated exactly like a room for design purposes. Each manufacturer maintains a list of systems with maximum nozzle heights. Rooms exceeding this height are effectively protected by several layers of nozzles, with each layer remaining within the height limit. Restrictions on system design depend on the specific manufacturers of the systems and their respective lists and statements.

Advantages of gas extinguishing

- does not spoil property;

- instantly localizes the place where the fire started;

- can be used everywhere;

- it has a low cost due to the repeated use of equipment, since only gas is subject to replacement;

- cylinders are insensitive to temperature changes, which makes them possible to use in unheated rooms;

- gases do not emit harmful substances when heated.

The company "SpetsPozhSistema" offers compact gas fire extinguishing installations for server, the cost of which you can see in the "Catalog" section on our website.

You should contact your specific system manufacturer to further clarify the restrictions on their specific system. If there was no fire, the agent can be safely and quickly removed using conventional air treatment and will not pose a threat to respondents or employees working in space.

In a typical electronic computer facility, fires are low energy, slow growth events. Early detection limits the potential for fire damage and combustion of products. However, modern electronics can emit a wide range of harmful by-products during combustion.

Convenience and security

When installing automatic gas fire extinguishing, the price in Moscow can fluctuate in different ranges. We offer the best products at affordable prices, which you can find on our website or by calling the contact numbers.

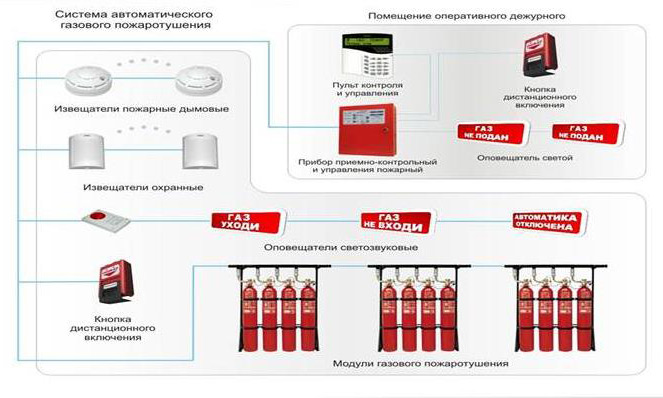

At the moment, the most popular is a system whose operation is subordinate to automation, capable of using sensors to detect both the presence of smoke and a change in temperature. It can turn off ventilation, stopping the supply of oxygen, and remove smoke from the room.

No residues will remain in the protected space, except for possible products of combustion from fire. Repeated fire tests were conducted, without any deactivation of the fire suits used by the technicians. With most installations, this can be achieved by simply turning on the ventilation units and enough time to disperse any smoke from the fire.

Some jurisdictions have implemented additional local requirements regarding ventilation systems. You should contact your local authorities. Sprinkler systems provide structural protection to an object or building. It is difficult to burn a brick or mortar. Both systems can be installed in a given space, but provide very different levels of protection against damage.

For calculation, you can leave a request on our website, and we will determine the cost of gas fire extinguishing. For the server room, library, airport - for each room it will be different.

The calculation includes:

- The volume of the cylinder to be used and its contents;

- Pipelines and fittings;

- Automation work;

- The design of the system, as well as its installation and commissioning;

- Commissioning.

In addition, we offer compact gas fire extinguishing installations for server rooms, the cost of which is lower compared to our competitors.

This, however, will also be a leak from space with equal ease. As a rule, it is recommended that you close doors and large openings before unloading the agent. This includes air vents, windows, and other normal openings. For room integrity, we recommend performing a room integrity check using the door fan unit. When all normal openings are closed, the door fan provides a small positive and negative pressure on the space and calculates the total cumulative volume of the openings.

The company "SpetsPozhServis" is your reliable partner in ensuring fire safety.

Gas extinguishing has more than a century of history. The use of carbon dioxide (CO 2) for extinguishing fires was first started at the end of the 19th century in Western Europe and the USA, but this method of extinguishing fires became widespread only after the Second World War, when refrigerants began to be used as the main component of GOS.

Using these data allows you to get the retention time of the concentration of the agent. This ensures complete extinguishing and minimizes the possibility of re-firing the fire. Contact us for more information on system components. There are many gas fire suppression systems on the market, but how do you know which one is right for you?

They can be divided into two categories; Chemical fire extinguishing and inert fire suppression systems. Inert gas fire extinguishing. Details in brackets are the chemical designation of the gas compound. How do inert gas systems work?

Basics and classification

Currently, regulatory documents in force in the Russian Federation allow the use of gas extinguishing agents based on carbon dioxide, nitrogen, argon inergen, sulfur hexafluoride, as well as HFC 227, HFC23, HFC 125 and HFC 218. According to the principle of operation, all GOS can be divided into two groups:

When discharged, they work by reducing oxygen in a room or room to below 15%. Below 15%, most combustible materials will not burn. At this level, oxygen life is stable, and healthy people would not have noticed any side effects. All of the above gases are approved for use in normally occupied areas.

Chemical fire extinguishing systems. The molecules absorb heat, so that the temperature of the flame drops to a point below which it cannot propagate, and the fire goes out. Fire extinguishing systems use pressure vessels, which must be respected by law. The test process is achieved by hydrostatic pressure in a pressure vessel containing a fire extinguishing agent.

- Deoxidants (oxygen displacers) - substances that create a concentrated cloud around the burning area, which prevents the flow of oxygen and thus "suffocates" the source of ignition. GOS based on carbon dioxide, nitrogen, argon and inergen belong to this group.

- Inhibitors (combustion suppressors) - substances that enter into chemical reactions with burning substances, which take energy from the combustion process.

According to the storage method, fire extinguishing gas mixtures are divided into compressed and liquefied.

A hydrostatic pressure test should be carried out every 10 years. The pressure vessel must be decanted, cleaned and dried. After removing the contents and dirt, the fire suppression cylinder is filled with water. Since water cannot be compressed when under pressure, it allows us to make sure that the cylinder is safe and suitable for the purpose.

When a fire disrupts your business operations, this leads to significant and unnecessary financial losses. The most common fire extinguishing material, water, can lead to greater financial losses than a real fire. This is especially true for server rooms or data centers and document storage areas. Often, downtime outweighs the loss of equipment and design, such as electrical switch rooms and transformer rooms. Using the right gas suppression system in the long run will protect you from significant financial losses.

The scope of gas fire extinguishing installations covers industries in which extinguishing with water or foam is undesirable, but contact of equipment or stored stocks with chemically aggressive powder mixtures is also undesirable - hardware rooms, server rooms, computer centers, ships and aircraft, archives, libraries, museums, picture galleries.

Most of the substances used for the production of GOS are non-toxic, but the use of gas fire extinguishing systems creates an environment unsuitable for life indoors (this is especially true for GOS from the group of deoxidants). Therefore, gas extinguishing systems pose a serious danger to human life. So on November 8, 2008 during sea trials of the Nerpa nuclear submarine, the unauthorized operation of a gas fire extinguishing system led to the death of more than twenty crew members of the submarine.

In accordance with regulatory enactments, all automatic fire extinguishing systems with GOS as a working substance must, without fail, allow the possibility of delaying the supply of the mixture until the personnel is completely evacuated. Premises in which automatic gas fire extinguishing is used are equipped with “GAZ! DO NOT ENTER! ”And“ GAS! GO! ”At the entrance to and exit from the premises, respectively.

Advantages and disadvantages of gas fire extinguishing

Fire extinguishing with the help of GOS has become widespread due to a number of advantages, including:

- fire extinguishing with the help of GOS is carried out throughout the volume of the room;

- extinguishing gas mixtures are non-toxic, chemically inert, when heated and in contact with burning surfaces, they do not decompose into toxic and aggressive fractions;

- gas fire extinguishing practically does not harm equipment and material values;

- after extinguishing, the emergency conditions are easily removed from the premises by simple ventilation;

- gOS application has a high fire extinguishing rate.

However, gas fire extinguishing also has some disadvantages:

- gas fire extinguishing requires room sealing

- gas fire extinguishing is ineffective in large premises or in open space.

- storage of equipped gas modules and maintenance of the fire extinguishing system is fraught with difficulties associated with the storage of substances under pressure

- gas extinguishing systems are temperature sensitive

- GOS are unsuitable for extinguishing a fire of metals, as well as substances that can burn without oxygen.

Fire extinguishing installations using GOS

The gas fire extinguishing installations according to the degree of mobility can be divided into three groups:

- Mobile gas fire extinguishing installations - fire extinguishing installations mounted on a wheeled or tracked chassis, towed or self-propelled ("Sturm" gas fire extinguishing installation).

- Portable primary extinguishing media - fire extinguishers and fire extinguishing batteries.

- Stationary installations - permanently mounted fire extinguishing installations using fire alarm systems, automatic and triggered by command from the remote control.

In non-residential premises, in warehouses and storages, at enterprises associated with the production and storage of combustible and explosive substances, automatic gas fire extinguishing systems are widely used.

Since gas fire extinguishing is highly dangerous for the enterprise personnel, in the case of installing an automatic fire extinguishing system using GOS in enterprises with a large number of employees, integration of the system automation with an access control and management system (ACS) is required. In addition, the automatic fire extinguishing system should, at the signal of the fire detectors, maximize the sealing of the room in which the fire is extinguished - turn off the ventilation, and also close the automatic doors and lower the protective shutters, if any.

Automatic gas fire extinguishing systems are classified:

- In terms of extinguishing, it is extinguishing the full volume (gas fills the entire volume of the room) and local (gas is supplied directly to the source of fire).

- According to the centralization of the supply of the extinguishing mixture, they are centralized (gas is supplied from the central reservoir) and modular.

- By the method of initiating the extinguishing process - with electric, mechanical, pneumatic, hydraulic descent or a combination thereof.

Equipping the facility with a gas fire extinguishing system

The initial calculation and planning of the installation of a gas fire extinguishing system begins with the selection of system parameters depending on the specifics of a particular object. Of great importance is the correct choice of extinguishing agent.

Carbon dioxide (carbon dioxide) is one of the most inexpensive options for GOS fire fighting. It belongs to fire extinguishing substances-dioxidants, in addition, it has a cooling effect. It is stored in a liquefied state, it requires weight control of substance leakage. Carbon dioxide-based mixtures are universal, the restriction to use is fires with the ignition of alkali metals.

Freon 23 is also stored in liquid form. Due to its high inherent pressure it does not require the use of displacing gases. It is allowed to be used for extinguishing rooms in which people can stay. It is ecologically safe.

Nitrogen is an inert gas, also used for fire extinguishing systems. It has a low cost, but due to storage in a compressed form, nitrogen-loaded modules are explosive. If the nitrogen gas fire extinguishing module does not work, it must be abundantly irrigated with water from the shelter.

The fire extinguishing steam installations are of limited use. They are used at facilities generating steam for their work, for example, at power plants, ships with steam turbine engines, etc.

In addition, before designing, it is necessary to choose the type of gas fire extinguishing installation - centralized or modular. The choice depends on the size of the object, its architecture, number of storeys and the number of individual rooms. Installation of a centralized type fire extinguishing installation is advisable to protect three or more rooms within the same facility, the distance between which does not exceed 100m.

At the same time, it should be taken into account that centralized systems are subject to a large number of requirements of the normative NPB 88-2001 - the main regulatory document governing the design, calculation and installation of fire fighting installations. Fire extinguishing gas modules, according to their design, are divided into unitary modules - they include in their design one tank with a compressed or liquefied gas extinguishing mixture and a gas displacer; and batteries - several cylinders connected by a collector. Based on the plan, a gas fire extinguishing project is being developed.

Designing a fire system using GOS

It is desirable that the whole range of work related to equipping the facility with a fire system (design, calculation, installation, commissioning, maintenance) be carried out by one executing company. Design and calculation of a gas fire extinguishing system is carried out by a representative of the installation company in accordance with NPB 88-2001 and GOST R 50968. Calculation of installation parameters (quantity and type of extinguishing agent, centralization, number of modules, etc.) is based on the following parameters:

- number of rooms, their volume, the presence of false ceilings, false walls.

- area of \u200b\u200bconstantly open openings.

- temperature, barometric and hygrometric (air humidity) conditions at the facility.

- the presence and mode of operation of personnel (ways and time of personnel evacuation in case of fire).

When calculating the estimates for the installation of fire extinguishing system equipment, some specific aspects should be taken into account. For example, the cost of one kilogram of a fire extinguishing gas mixture is greater when using modules with compressed gas, since each such module contains a lower mass of substance than a module with liquefied gas, therefore, the latter will need less.

The cost of installation and maintenance of a centralized fire extinguishing system is usually less, however, if the facility has several sufficiently remote rooms, the savings are “eaten up” by the cost of pipelines.

Installation and maintenance of gas extinguishing stations

Before starting installation work on the assembly of a gas fire extinguishing installation, it is necessary to make sure that there are certificates for the equipment subject to mandatory certification and check the installation company for a license to work with gas, pneumatic and hydraulic equipment.

A room equipped with a gas fire extinguishing station is necessarily equipped with exhaust ventilation to remove air. The rate of air removal is three for chladones and six for deoxidants.

The manufacturer carries out the installation of fire extinguishing modules or centralized balloon tanks, trunk and distribution pipelines and starting systems. The modular or centralized pipeline part of the gas extinguishing station is integrated into a single automated control and monitoring system.

Pipelines and elements of an automated control system must not interfere with the appearance and functionality of the premises. Upon completion of installation and commissioning, an act of completion is executed, and an act of acceptance and transfer to which are attached test reports and technical data sheets of the equipment used. A maintenance contract is concluded.

Performance tests of equipment are repeated at less than once every five years. Maintenance of gas extinguishing systems includes:

- regular tests of the performance of gas extinguishing station elements;

- routine maintenance and equipment repair;

- weight tests of modules for leakage of GOS.

Despite certain difficulties associated with installation and use, gas fire extinguishing systems have a number of obvious advantages and high efficiency in their field of application.