Various fire extinguishing installations. Fire alarm and fire extinguishing means automatic fire extinguishing system

Many facility managers are not serious about the issue of choosing equipment for fighting fire, believing that nothing like this will happen to them.

As a result, when a fire occurs, completely inappropriate substances are often used to eliminate it.

To prevent this from happening, it is necessary to entrust the choice of installing fire extinguishing systems to professionals. Only they are able to correctly assess the specifics of an object and determine which type of equipment will be most suitable.

What is the installation data

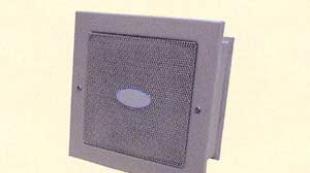

This is a set of devices that are triggered if the critical values \u200b\u200bof temperature, smoke in the protected object are exceeded. Autonomous fire extinguishing installations are usually used to localize and eliminate the source of fire at the very beginning of its appearance.

The use of such equipment is regulated by existing regulatory documents and is recommended for both residential and public, industrial buildings.

The use of such equipment is regulated by existing regulatory documents and is recommended for both residential and public, industrial buildings.

AUP Variety

The equipment used to eliminate the sources of ignition is structurally different. Depending on this parameter, it can be of the following types:

- Aggregate;

- Modular.

In addition, fire fighting installations are equipped with automation. Based on the presence of these elements, the equipment involves manual control or using automation systems.

![]() Automatic fire extinguishing installations can work with various types of OM. Moreover, models are presented on the market in which one of the means is used, as well as several.

Automatic fire extinguishing installations can work with various types of OM. Moreover, models are presented on the market in which one of the means is used, as well as several.

Such a large number of means used to eliminate the fire has led to the emergence of various methods of fighting fire. Based on this, the following types are produced:

- Robotic fire extinguishing installations;

- Voluminous;

- Superficial;

- Local.

What are the different types of equipment, where their use is allowed, what advantages do they have, the purpose of an automatic fire extinguishing installation? We start the review with one of the simplest and most affordable substances - water. It is affordable and has a low cost.

Water models

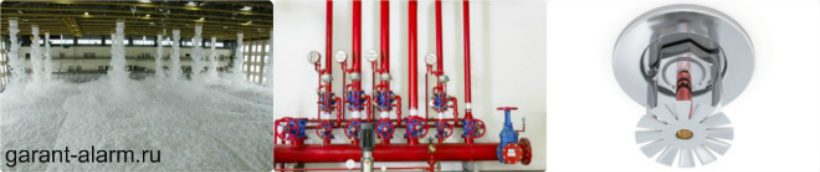

Systems working with this extinguishing agent have differences in the design of sprinklers. They can be:

- Sprinkler

- Deluge.

The first are designed facilities on which there are materials with high flammability. In them, the elimination of fires should be carried out simultaneously over the entire area of \u200b\u200bthe room.

Fire extinguishing systems can play the role of water curtains in cultural and public institutions, and are also suitable for extinguishing process equipment, containers with oil products. They perfectly cope with the creation of a water curtain.

Gas installations

This is a set of devices for eliminating sources of ignition, in which two groups of gases can be used as OM:

- Thinners such as nitrogen, argon;

- Inhibitors or chladones.

Using the first group of fire extinguishing substances are large in size and weight. While working with inhibitors is more compact, but at the same time, the concentration of gases in them is significantly lower and amounts to only 13% of 60% for the first group.

Not so long ago there were systems that use perfluoroketones. They are characterized by high environmental safety and can be used at any facilities, as they do not have a detrimental effect on objects and materials.

Watch a video about these systems:

Stationary gas fire extinguishing installations have differences in design and are divided into:

- Modular;

- Centralized.

Powder systems

Such installations have the widest scope. They are designed to eliminate foci of fire of any class, as well as electrical appliances that are in the on state.

Watch a video about this system:

Autonomous fire extinguishing installations for switchboards are used both for localization and elimination of fire sources in parts or all areas of a room. But at the same time, such settings can not be used on objects where they are stored:

- Combustible materials;

- Chemical mixtures that can smolder and burn without air.

Devices of this type are most often used at facilities where combustible liquids and rapidly flammable compositions, oil products are located. They are divided into deluge and sprinkler fire extinguishing systems and, in a constructive sense, are very similar to water installations. Their difference consists only in the presence of a tank. In this case, all components of the extinguishing agent are stored separately.

For the dosage of OM in such installations can be used:

For the dosage of OM in such installations can be used:

- Pumps

- Dispensers;

- Foam mixers;

- Bucky

In addition, sprinklers or generators are used in foam systems.

Aerosol systems

In them, as a fire extinguishing agent, a special composition is used that can affect the focus of the fire. They are one of the oldest and were first used in 1819. In the first autonomous fire extinguishing systems, smoke powder, clay and water were used as the extinguishing agent. But over time, their use was suspended due to low efficiency.

Watch a video about this fire extinguishing system:

Modern stationary aerosol fire extinguishing installations cannot ensure the complete elimination of the fire source and therefore they cannot be used for:

- Fibrous and other materials with a tendency to spontaneous combustion or decay;

- Chemical compositions and polymers capable of burning without air;

- Metals, pyrophoric compounds.

As well as aerosols are harmful to human health, therefore, installations where they are used cannot be used in rooms that people cannot leave before the system starts working.

How to choose a fire extinguishing system

The most important criterion, which are guided in this case, are the features of the object. Based on them, a specific robotic fire extinguishing installation is selected. If it is supposed to use equipment in buildings of public, warehouse, archival and cultural purposes, then immediately you can discard the use of foam as a fire extinguishing agent. In addition, it has recently been practically not used at any of the possible facilities.

Based on the features of the protected premises, you can formulate the main selection criteria:

- Efficiency;

- Safety for people;

- The inability to damage property.

Under these criteria, systems with solid extinguishing agents are most suitable. It is possible to use water pumping fire extinguishing systems, since horses are safe for people. But at the same time, property suffers from them very much. And if such a system works on the upper floor, then tons of water will fall on the lower ones, which will damage both material values \u200b\u200band the building itself.

Therefore, most often fire extinguishing pumping units are used with fine atomization systems, which minimize the impact on the environment.

Perhaps the use of gas SAPT. However, their use, especially with freon, is deadly to humans. Therefore, at facilities where people are present, they usually prefer a group of perfluoroketone gases. They are practically safe. But it should be borne in mind that the premises where the use of gas systems is supposed to be met are subject to strict requirements for tightness, and besides, such equipment is quite expensive.

Maintenance and operation

It is not enough to make the right choice, it is also necessary to complete the installation of equipment in accordance with existing requirements. After pipelines are completed and devices are installed with their connection to the mains, it is necessary to conduct tests. By the time of their implementation, it is necessary to assess the strength and density of all pipes, check the quality of insulation of the wiring.

It is not enough to make the right choice, it is also necessary to complete the installation of equipment in accordance with existing requirements. After pipelines are completed and devices are installed with their connection to the mains, it is necessary to conduct tests. By the time of their implementation, it is necessary to assess the strength and density of all pipes, check the quality of insulation of the wiring.

Testing a fire extinguishing pump installation consists of several stages. At the first, inspection of equipment, both technological and electrical. Then, autonomous tests of individual nodes of the system responsible for managing its operation are carried out.

External inspection also involves checking whether the placement of devices corresponds to the design drawings. Autonomous tests are necessary to assess the correct interaction of all nodes and elements of the system. All work and the commissioning of the installation are confirmed by the acceptance certificate. They must be accompanied by design drawings and other documentation.

Fixed fire extinguishing installations serve to eliminate fires in the initial stage of their occurrence without the participation of people. These installations are housed in buildings and structures. According to the types of extinguishing compounds used, they are divided into water, foam, gas, powder. Water and foam installations are branched piping systems with holes closing special. Depending on the arrangement of the heads, sprinkler and deluge units are distinguished. They are divided into automatic and manual with remote start.

Automatic fire extinguishing systems are designed to quickly eliminate the fire. There are several types of equipment that should be selected based on the structure of the building, the environment, and the source of fire.

General information about fixed fire extinguishing installations

Foam

Suitable for exposure to flammable liquids. Basically, they protect buildings and various electric devices. The installation may contain various substances, as there are tanks for their separate storage. They depend on the sources of water supply, as they provide the irrigation fluid.

The composition and principle of operation of the foam fire extinguishing installation are in many respects similar to the water extinguishing installations. Additional elements in foam installations are foam generation devices (sprinklers and generators), as well as storage and dispensing systems for the foaming agent. In addition, the difference between foam systems and water systems is that non-potable water pipelines should serve as a source of water supply for foam fire extinguishing systems, while the amount of water required to produce foam must meet the requirements of technical documents for the foaming agents used.

Automatic foam fire extinguishing installations are classified according to functional features and design features based on the multiplicity of the foam used, start-up time, duration of their operation, method of feeding and obtaining a foaming solution, type of foaming devices and method of filling pipelines.

Depending on how much the volume increases compared to the original, the foams are low (up to 20), medium (from 20 to 200) and high (over 200) multiplicity. Accordingly, fire extinguishing installations are divided into extinguishing installations of low, medium and high multiplicity.

According to the method of exposure to the fire, foam installations are divided into installations of general surface, locally surface, general volume, local volume and combined extinguishing:

- General surface - deluge, to protect the entire working area;

- local-surface: sprinkler - to protect individual devices, individual sections of the premises; deluge - to protect individual objects, devices, transformers, etc .;

- general - designed to fill the protected volumes;

- locally volumetric - to fill certain volumes of technological devices, small built-in storage facilities, etc .;

- combined - connected schemes of local-surface and local-volume quenching systems for simultaneously supplying foam into the volume or along the surface of technological devices and to the surface around them.

Foaming solution in foam AUP can be obtained by the volumetric method (preliminary preparation of an aqueous solution of the foaming agent in the tank, from which it is supplied to the distribution network by pumps) using inkjet devices, automatic dispensers, and pump dosing systems.

According to the method of filling the pipelines, foamy AUPs can be dry-tube, filling, and circulating. Dry-tube installations are filled with a foaming solution to shut-off and start-up devices, therefore, when the unit is turned on, it takes some time to fill the pipelines.

In order to reduce the on-time of foam AUP, the method of filling pipelines to sprinklers (in foam AUP sprinkler type) or to the level of distribution rows in risers (in foam AUP of deluge type) is used.

In high-speed installations, a method of constantly circulating a foaming solution in pipelines is used, which significantly increases the operational readiness of foam AUP.

Water

It can be used in rooms with high fire hazard. The principle of operation is that with the help of dispensers and pump units, the desired area is irrigated with water. This allows the fire to move on.

Separately, it is worth mentioning the varieties: for example, you can purchase fire extinguishing installations with finely sprayed water. It can be used in residential premises, as it is harmless to human health.

Currently, water extinguishing systems are divided into the following types:

- sprinkler fire extinguishing systems;

- sprinkler fire extinguishing installations with remote start;

- fire damping systems;

- modular fire extinguishing systems with finely atomized water (MUPTV EI-Mist).

Water fire extinguishing has proved to be the best for many years and is constantly being improved. Along with sprinkler and deluge extinguishing, which is a network of pipelines for supplying water to the combustion zone, pumping stations and irrigators, modular fire extinguishing systems for fine-dispersed water (MUPTV) are currently becoming increasingly common.

Water fire extinguishing is the most common fire extinguishing system that has the greatest number of advantages in eliminating a fire. Water fire extinguishing systems can be used in places of mass presence of people, in addition, sprinkler fire extinguishing systems are able to perform fire alarm functions (launch people warning systems in case of fire, transmit signals to shut down process equipment, power supply, start smoke removal systems).

Gas

Such installations help to extinguish fires due to the fact that the tanks contain a special gas composition (for example, freon, nitrogen or argon). With the help of distribution devices, they economically consume the substance, which allows it to be used on large areas.

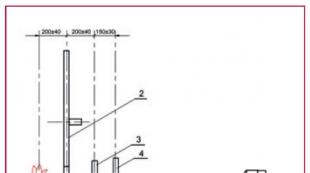

In gas fire extinguishing, special fire extinguishing compositions are used to effectively extinguish fires and fires of various etymologies. Typically, an automatic installation of this type consists of cylinders that store special gas under pressure, control units, sprayers and pipelines, with which gas is delivered and released to the premises, as well as a control panel and mandatory fire detectors.

The gas fire extinguishing installation consists of a special cylinder with liquefied gas, which is fed through a pipeline and a special nozzle. It is mandatory to have a device with which control and notification of a fire is performed.

Relatively recently, automatic gas fire extinguishing installations have begun to be used, in which freon of various modifications is used: freon 23, freon 227еа, freon 125. Freon 23 and freon 227еа can be used in rooms where people are present. And Freon 125 is used to extinguish fires exclusively in uninhabited rooms. To protect archives and safes from fire, carbon dioxide is often used.

Automatic gas fire extinguishing systems are indispensable if fire extinguishing can cause a short circuit or damage expensive equipment and property of the archive, server, museum or library.

The gas fire extinguishing system must fulfill the following important functions:

Detect a fire in a timely manner using the fire alarm that the system is equipped with;

to delay the supply of extinguishing gas during the evacuation of people from the premises;

quickly create a concentration of gas that should be enough to extinguish a fire.

In the protected and adjacent rooms, which have access only through the room with the installed system, when triggered, sound and visual warning devices are activated, as provided for in GOST 12.3.046 and GOST 12.4.009.

The gas fire extinguishing installation is part of the explosion suppression systems and is used for phlegmatization of explosive substances.

Now gas extinguishing is a popular and effective method of fighting fires.

Extinguishing a fire with gas installations does not lead to a short circuit. It will not damage objects in the ignition zone. With this installation, you can successfully fight fire in offices with a lot of expensive equipment, in server rooms, where there are a lot of wires, and on board an airplane. This method of extinguishing fires is suitable for museum or bank premises, archives, warehouses, mini substations, cable routes, etc. The gas fire extinguishing system will not only allow you to quickly cope with the fire, but also save valuable documents, exhibits or money.

The advantages of gas fire extinguishing systems include the following facts:

Such a system is absolutely safe for electronics, documents and other values.

You can put out a fire in minutes.

Installations of this type comply with international standards.

One battery of cylinders is enough for independent protection of several rooms. The fire will be eliminated in several zones at once.

You can adjust the load time, as well as the concentration of the extinguishing agent.

Installations of this type are easy to operate and maintain. They are very durable.

Gas quenching

In fire extinguishing, as a rule, two types of gas are used: freon and nitrogen or argon.

Freons of various types (23 or 125) reduce the burning rate. The fire is gradually eliminated. These gases are completely safe for human life and health. They can be used in rooms in which people are located.

Nitrogen and argon are gases that reduce the concentration of oxygen in the air. With their help, you can also quite effectively deal with fire, which, as you know, does not burn without oxygen. But for extinguishing a fire in rooms with people, this method is absolutely not suitable!

Gas extinguishing system requirements

A system of this type should as soon as possible detect the source of ignition and report it.

During a fire, people should have enough time to leave the room. Therefore, the cylinder must be equipped with a special system for delaying gas for some time.

The gas flow rate should be sufficient to eliminate the fire in the shortest possible time. For example, the famous “Sturm” installation can cope even with a large fire in a gas well in just 3 to 5 seconds.

Periodically (every 5 years), it is necessary to conduct the response time of the system, the intensity of the gas extinguishing agent and its concentration.

Powder

Such automatic stationary fire extinguishing installations are used mainly in order to prevent the spread of fire throughout the premises. Unlike previous varieties, they are not suitable for extinguishing fires associated with combustible and chemical materials. In addition, they do not guarantee a fire stop: in addition, other extinguishing agents, such as water, must be used. It is important not to use in rooms with high traffic, as fuel can harm the human body.

Fire extinguishing powders and fire extinguishing installations based on them are used to protect the following series of objects:

- industrial premises;

- warehouses (with storage of wood products, furniture, varnishes, paints, glues, alkaline materials, fuels and oils);

- household pantries;

- spray booths and dryers;

- vehicle maintenance stations;

- garages;

- locomotive depots;

- trade enterprises;

- left-luggage offices;

- power plants;

- rooms with diesel generators;

- electrical cabinets, transformers and live electrical equipment;

- premises of administrative buildings;

- external technological installations;

- open grocery pumping;

- overhead loading racks and tank farms;

- gas distribution substations and others.

Installations should not be used to extinguish fires:

- combustible materials, prone to spontaneous combustion and decay inside the volume of the substance (sawdust, cotton, grass meal, etc.);

- chemicals and their mixtures, pyrophoric and polymeric materials, prone to smoldering and burning without air.

The main advantages of extinguishing powders, unlike other types of extinguishing agents, are:

- due to its physicochemical properties, high fire extinguishing ability and versatility of use;

- quick suppression of the source of ignition without human intervention and relatively low cost;

- environmental friendliness (lack of toxic components, ozone-depleting substances, low corrosion activity, chemical inertness), because the basis of the powders are mineral fertilizers;

- in comparison with water and foam extinguishing installations, they cause minimal indirect damage from a fire caused to the premises and property located in it - the extinguishing powder is easily removed with a vacuum cleaner or a broom;

- the possibility of use at low temperatures, when the use of water, foam, and other means is inefficient, economically disadvantageous, or unacceptable;

- compared to gas and aerosol extinguishing installations, low demands on the tightness of the premises.

Aerosol

Are applied at the enterprises at which there is no possibility of ignition of chemicals. Also not suitable for places with low tightness. Cannot be used to extinguish loose substances that are prone to spontaneous combustion (e.g. cotton, sawdust). It is not recommended to use powders of metals and pyrophoric substances for eliminating fires. Remember that aerosol installations can be used in rooms with a patency of not more than fifty people a day.

Before choosing a fire extinguishing installation, be sure to consider where it will be installed, since during installation this will save you time.

Advantages of aerosol fire extinguishing:

- High efficiency. According to research, solid fuel aerosol-forming compounds (AOS) have the greatest fire extinguishing ability, in comparison with other means of volumetric fire extinguishing.

- Universality. It can be used where it is impossible to use alternative methods of volumetric fire extinguishing, for example, to protect unheated rooms, live electrical equipment, etc.

- Low cost. It has a low cost compared to other types of fire extinguishing systems.

- Easy installation. It does not require the installation of additional equipment and supply of communications.

- No maintenance required. Fire extinguishing aerosol generators do not need recharging and are always ready for action.

- It does not harm the protected object. Both the room and the material assets located in it will not cause harm. The aerosol settled in the form of powder is easily removed from the surface.

- Environmentally friendly. It does not harm the ozone layer of the planet.

Scopes of fire extinguishing aerosol generators:

- industrial, office buildings, warehouses, storage facilities, offices, laboratories, etc.

- rooms of power distribution devices, transformer substations

- electrical cabinets, cable tunnels, switching assemblies, rooms for technological operator and computing equipment and other rooms with electrical installations and electrical equipment

- covered parking garages

- apartments, residential houses, dachas, temporary residential premises of a modular type (trailers, vans)

- vehicles: protection of compartments of buses and trolleybuses, ground railway transport, special vehicles, sea and river transport

From ancient times to the present, fires have been a serious problem in people's lives. Some especially strong fires go down in history and change the life of entire cities and even states. So it was, for example, with the Great Fire of London in 1666 or with the famous fire of Moscow during the Patriotic War of 1812. Therefore, it is logical that each property owner seeks to protect himself from fire.

Modern fire-fighting systems provide a high level of security, but the issue of economic efficiency in this case is no less important. It is unlikely that someone will want to pay a lot of money for an automatic fire extinguishing installation if the probability of a fire at this particular facility is extremely small.

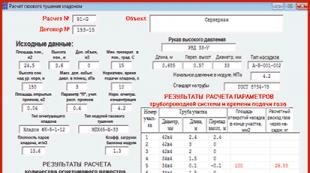

The main criterion when choosing a fire extinguishing system and the amount of money that the owner of the object is ready to spend on it is the potential damage that may be caused in the event of a fire. In order to navigate the different versions of fire protection systems, the formula S \u003d A + B is used, where A is the estimated losses (thousand rubles per year) from a fire at a protected facility after the system is triggered, and B is the development, installation and annual maintenance of an automatic fire extinguishing installation.

It should also be noted that the alleged losses include not only the actual destruction of property, but also the income that will be lost due to failure of the burned equipment. When analyzing various options for fire extinguishing systems, the one that assumes the lowest S value will be most preferable.

You can often find an option in which only a fire alarm is installed at the facility. It is an effective means of detecting a fire, however, this is where its functions end, since it cannot actually extinguish a fire. At the same time, the state fire protection system is not as fast as many property owners would like - the average time for the fire brigade to arrive is about 10 minutes. This is a significant period of time during which many values \u200b\u200bcan be destroyed permanently by fire.

In addition, in recent years there has been a tendency to increase this time. In large and medium-sized cities, population growth leads to the fact that the number of cars increases, and the throughput of roads does not change. As a result, there are traffic jams that are difficult for a fire engine to overcome even with a flashing light and a siren. In rural areas, the situation is no better, but it is not a traffic jam at all. Lack of road repairs, understaffed crews, outdated equipment - all this is the reason for the increase in the average time of arrival to a fire.

In order to completely protect themselves from fire or at least minimize its consequences, automatic fire extinguishing installations (AUP) are used at various facilities. They are able to independently detect and extinguish a fire without human intervention. It often happens that the operator learns about the fire after it is extinguished.

Automatic fire extinguishing systems differ from each other in several ways. Although they are designed to serve one purpose, their device is sometimes fundamentally different from each other. The table below shows the most common classification methods for automatic fire extinguishing installations:

|

AUP classification |

|||

|

By type of extinguishing agent |

By design |

Extinguishing Method |

By way of commissioning |

|

Sprinkler |

By volume |

Manual start |

|

|

Deluge |

By area |

Auto start |

|

|

Powder |

Aggregate |

Locally to the fire |

Remote start |

|

Modular |

Combined method |

||

|

Aerosol |

|||

The most popular, reliable and simple automatic fire extinguishing system is the sprinkler. These installations, due to their effectiveness, are used in almost any facility, including of particular importance. According to statistics, more than 90% of fires in the world are extinguished by just such systems.

Sprinkler units operate according to the following principle. Pipes filled with water or an aqueous solution that is under pressure are mounted throughout the room. At certain intervals, locks are installed in the pipes, which serve as thermal sensors. In most cases, they are designed for temperatures around 70 ° C.

When a fire occurs, the sprinkler that is located closest to the source of fire is triggered. For example, if pipes are laid under the ceiling, and a fire starts on the floor, then the thermal lock will collapse in 2-3 minutes. All pipes of the system covering the room are connected to a common highway in which automation equipment is located. The line, in turn, is connected to a pump, which creates pressure in the entire automatic fire extinguishing installation.

Under normal conditions, the system is pressurized, with all safety valves closed. When a fire starts, the thermal lock starts to heat up. The design of the lock is a glass flask filled with a special substance, and a stopper-valve.

When heated, the substance in the flask expands and upon reaching a known temperature (which is determined by the brand of the castle and the type of substance) destroys the glass shell. The plug-valve is pushed out of the pipeline, and water immediately begins to flow into the fire.

Automatic sprinkler fire extinguishing installations are good in that in a fire only those locks near which there is fire are destroyed. This significantly saves water consumption and allows you to protect other materials from it that the fire has not reached.

Although the water in the system is under pressure, its supply will soon run out, since after opening even one or two locks, a significant amount of extinguishing agent falls on the fire. To ensure that the fire is extinguished, pressure sensors are installed in the pipelines. They record its decrease, which inevitably occurs after the destruction of the thermal lock, and sends the corresponding signal to the control unit.

The unit starts up the main pump or turns on the backup pump if the first one fails. Pump operating time, as a rule, is from half an hour to an hour. One thermal lock can cover an area of \u200b\u200b9 to 16 m².

Despite the general principle of operation of thermal locks, sprinkler systems can differ from each other in many parameters. For example, they can be coated with a special composition that protects them from corrosion, or made of refractory material. The dimensions of the sprinklers are of great importance, as well as the scope of their application - the systems for offices and warehouses are very different from each other. Modern sprinkler systems are compact and almost do not attract attention with their appearance.

For objects that do not have heating, the use of water in automatic fire extinguishing installations loses its meaning because of its possible freezing. In these cases, compressed air is supplied to the sprinklers, which presses on the shutter of the protective valve. Water is higher up the pipes and is fenced off from the “air plug” by a special valve. The main fluid reservoir is located in a heated room. In addition, the system further includes a compressor for maintaining air pressure. Otherwise, the principle of operation of such a sprinkler system is identical to a system operating only on water.

Speaking about the advantages of sprinkler fire extinguishing systems, it is worth mentioning their disadvantages. Imagine that a fire occurred in a warehouse of petroleum products or other flammable liquids. In this case, the fire will spread quickly enough, without waiting for each thermal lock to work.

How to protect materials? To do this, use deluge automatic fire extinguishing installations, which are also called flooding. The principle of their work is to use special fire sensors located throughout the room. The valves of the system do not open as a result of heat damage, like sprinklers, but upon the command of the control unit.

Having received information from the sensors about the start of the fire, the controller opens all the valves, regardless of which zone of the object the fire started. The room is completely flooded with water or a special solution, not allowing the flame to spread to neighboring objects.

To protect material assets and at the same time to effectively extinguish the fire, special installations are used that combine the features of sprinkler and deluge fire extinguishing systems. They are also called pre-action systems, and represent one deluge valve on a common fire extinguishing line, and classic “on-site” sprinkler valves. In addition, thermal sensors are installed in the room, tuned to a value lower than the temperature of the destruction of thermal locks.

In the normal state, the system is not filled with water, unlike sprinkler systems in their pure form. In the event of a fire, first of all, the sensor of the deluge system is activated, since its temperature is lower than that of sprinklers.

This sensor opens the deluge valve in the common line, as a result of which water enters the system, but does not pass further than the sprinklers. If during this time the fire is not detected, or it does not have time to be extinguished by primary means, the temperature will continue to rise, and the destruction of sprinklers will begin. If the fire is extinguished in advance, extinguishing with large volumes of water will not be required, and this will save property.

To avoid possible water consumption and damage to property, additional protective elements can be added to the deluge valve system for which different operating conditions are set. The number and type of protective elements are determined by the safety requirements at each specific facility. Thanks to such equipment, you can get a reliable fire extinguishing system with flexible settings.

For example, pre-action installations are often used in libraries, storages or museums, where water can completely destroy existing values. Also, in these systems, equipment is additionally installed to create finely atomized water, which cools the fire in the same way as ordinary water, but otherwise acts as a non-combustible gas and does not harm paper or paintings. The extinguishing process is controlled by temperature sensors, which, when it is reduced to a predetermined value, completely shut off the water supply.

If the fire is not completely extinguished, and the temperature begins to rise again, the automation will restart the pumps. Such systems, already more advanced, work without human intervention and are called cyclic. They are especially valuable in that they can be used to protect repositories of harmful and toxic substances, where a constant human presence is undesirable or excluded. Water or foam is used as extinguishing agent in such systems.

Ordinary sprinkler or deluge systems can also use foam. This requires special equipment for the formation of foam: a reservoir for foam concentrate, a dispenser for mixing the concentrate with water, as well as valves, electric drives and a control and automation system.

A more advanced automatic fire extinguishing installation is a system using finely dispersed water. Water has such a name because it is supplied under high pressure through very narrow nozzles. Thus, water enters the combustion zone in the form of tiny droplets and more effectively displaces oxygen.

Water can also be mixed with non-combustible gas, making the quenching process even faster. The equipment for such systems is more complicated than for conventional sprinkler or deluge systems, however, these costs are offset by a smaller tank volume and low water consumption. In addition, the high rate of extinction significantly reduces material damage from fire and water.

Finally, automatic gas fire extinguishing installations use non-combustible gases as nitrogen, carbon dioxide, some inert gases, etc. Similar systems are used where the use of water can cause even greater damage than the fact of a fire. The disadvantage of such systems is the strict requirements for the evacuation of personnel, since gases block the access of oxygen not only to fire, but also to people. A variety of gas plants are powder systems that use a mixture of dry non-combustible materials instead of gas. Most often they are used to extinguish closed electrical installations, the use of water in which can lead to a short circuit

.

.

The legislation of the Russian Federation obliges the owners of facilities to equip them with automatic fire extinguishing means, the options for which are determined by the purpose of the building and the potential damage that may be caused by a fire.

For some rooms, the rules are limited by the requirement to install fire shields with the simplest means of protection, however, for many objects, especially in industry, automatic fire extinguishing installations are required. Unfortunately, they are not always established, as required by regulatory enactments.

Some property owners do not have the means to do this; others buy cheaper and less reliable installations. Worst of all, and this is common enough when the owners knowingly do not use protection, believing that the fire will not affect them.

Despite the fact that the introduction of automatic fire extinguishing installations in critical facilities has long been enshrined in law, there are still designers and property owners who stubbornly do not want to spend money on this. They expect that the fire will bypass them, however, as often happens, it comes to those who did not take care of their safety in advance.

That is why the development of a fire extinguishing system must be approached from the opposite side, considering that a fire will occur. And it will not just happen, but will be as strong as possible in order to destroy all buildings and values. Based on this, the optimal composition of the fire system should be chosen. Typically, developers are guided by the following criteria:

- Safety for people;

- Security for property;

- Extinguishing rate;

- The complexity of installation and maintenance;

- Environmental Safety;

- Price.

After that, the study of the features of a particular object begins. Consider the choice of an automatic fire extinguishing installation for such a building, where a lot of paper documents or similar values \u200b\u200bare stored - a museum, library or archive.

Implementation of a fire extinguishing system in libraries and similar facilities

Modern technology involves the storage of information on special media. Thousands of pages of information easily fit on a small memory card that weighs less than one gram. However, there is a lot of information that is forcedly stored on paper. These can be various archival documents that should be stored for several years, but they are in no hurry to translate them into electronic form.

It can be money in a bank, or books in a library. Finally, many paper media are no less historical value than the information they contain. Imagine the original work of Shakespeare or Pushkin, reflecting the spirit of those times, and the importance of fire protection will increase at times. Also in this category can be attributed paintings and in general most of the values \u200b\u200bstored in museums.

All this makes libraries, banks, archives, museums and similar objects the premises where the installation of automatic fire extinguishing systems is strictly required. In addition to the actual fight against fire, they are subject to stringent requirements for the speed of operation and type of extinguishing agent.

The speed should be minimal after detecting a fire, and the extinguishing agent should not damage the storage media. This is especially true of repositories of historical documents, since even a slight change in temperature or humidity in them can lead to destruction of paper.

Thus, the listed factors form two basic requirements for automatic fire extinguishing installations at facilities of this type:

- The extinguishing agent must extinguish the fire extremely quickly and prevent its spread;

- The extinguishing agent must not damage material values.

From these requirements, it is clear that water - such a popular means of fighting fire - is not suitable for use on objects of this kind. The reason is clear: under the influence of water, the paper softens, as well as the ink on it spreads and spreads. As a result of this, not only information can be lost, but also the medium itself, which is completely unacceptable for storing values. In addition, water can trigger complex chemical processes in which destructive substances can penetrate deep into even paper untouched by fire and water, which in the future will also lead to their loss.

Foams or powders are more attractive extinguishing agents, but even upon closer examination they are excluded from the list of extinguishing candidates. The fact is that they all fight fire through a chemical reaction. At the same time, the powder does not make out what needs to be extinguished, and equally affects both fire and other substances in the room. Another minus in favor of aerosols is the high starting temperature of these substances. Sometimes it is so high that they themselves can become sources of ignition of paper.

It is also undesirable to use systems based on aqueous salts of metals of the first group of the periodic table - sodium or potassium. They act on fire chemical methods even more actively than aerosols and powders, but on other substances, their effect is extremely strong. In addition, they cause inflammation of the eyes and skin of a person, which forces them to be abandoned when protecting libraries and repositories of valuable materials.

As a result, non-combustible gases are best suited for the role of extinguishing agent for objects of this purpose. True, this method has its opponents, who argue that gas installations do well only with open fire and poorly detect smoldering sources. Moreover, the previous legislative norms prescribed to have additional facilities at the facilities for the production of finely dispersed water to guarantee the suppression of any fire. This approach, indeed, allows you to cope with fire in all cases, however, the risk of damage to material assets is also quite large. The developers had to implement these systems in order to donate several documents in order to avoid re-ignition.

Fortunately, the new automatic gas fire extinguishing installations are free from the drawbacks of all their predecessors. Special chemical compositions allow the extinguishing agent not to remain on the surface of materials, but to penetrate into the smallest pores deep into the paper. Thus, smoldering documents are detected and eliminated at an early stage, and re-ignition does not occur. This is especially important for thick bundles of paper - for example, for bank vaults, since the fire likes to "get stuck" in the thickness of documents.

Conclusion

This article examined the basic automatic fire extinguishing installations and the principles of their operation. Also, criteria for one or another choice of fire systems were presented here. Remember that when choosing many options for fighting fire, you should first of all focus on safety. At the same time, it is important to consider both the safety of people and the safety of material values. One and the same type of installation can play a decisive role in extinguishing a fire in one case, and cause even greater material damage in another. The design of automatic fire extinguishing systems is a complex and responsible process that requires comprehensive comprehensive consideration.

A fire extinguishing installation is a group of means by which you can extinguish a fire while releasing fire extinguishing substances. Such installations are manual or automatic. Let us dwell in more detail on the second type of installations, which at the same time operate as a fire alarm, that is, they give a signal if a fire is detected.

Extinguishing a fire with improvised means or forces of a fire brigade has long been no longer an actual method of fighting fire at large facilities. As the main means of protection against fire, they use automatic fire extinguishing installations, which differ from each other in the device, dimensions and type of extinguishing agent.

Therefore, to select a fire extinguishing installation, several factors must be taken into account. Such a system should monitor the situation at the facility, notify people about the start of a fire and begin to extinguish it independently. These requirements are true for residential premises, and for offices, warehouses or industrial enterprises.

One of their popular fire extinguishing systems is the installation of installations that incorporate GSM-range signaling. This means that the equipment not only controls the fire situation and starts to extinguish the fire in automatic mode, but also informs the person about it by calling or sending SMS to a regular mobile phone.

After receiving a signal from the sensors about a fire, the system can be activated in two ways:

- Automatic, in which fire valves open and the pump starts when a signal is received from the controller in the system control unit;

- Manual, in which the start of fire-fighting equipment is performed by the controls on the operator panel or directly in the control panel at the facility.

As for the supply of extinguishing agent, in this case, two options for a fire extinguishing system are also distinguished:

- Supply of extinguishing agent directly to the fire zone;

- Spraying the extinguishing agent throughout the area or volume of the room where a fire is detected.

Extinguishing agents

Extinguishing agents are the basis of any fire extinguishing installation. Depending on the purpose of the object and the type of materials to be protected, the substances may be different. Consider the most common of them.

- Water. Water is the most proven and popular means of fighting fire. It is usually used in sprinkler systems, that is, in those where it is supplied only to the source of ignition. This method is very effective (more than 90% of fire extinguishing installations worldwide), although it requires large volumes of water and, accordingly, additional equipment for its storage and pumping. Water is used to extinguish materials that are easily exposed to fire. At the same time, water affects not only fire, but also other materials and valuables in the room. Therefore, its use in libraries, museums and other similar buildings is impractical, and sometimes completely prohibited.

Another disadvantage of water extinguishing systems is their low efficiency - only about a third of the consumed water is actually involved in the extinguishing process. To avoid unnecessary costs, it is necessary to install a fire extinguishing system with fine spray water technology.

This method combines the functions of ordinary water, which effectively cools the burning surface, and non-combustible gas, which blocks the access of oxygen to the combustion zone. In this case, water saving is up to 30%, and the rate of fire localization and extinguishing is higher than when using classical methods.

- Powders and foams. These substances do not require such a large flow as water, therefore they are used everywhere in residential and administrative buildings, in factories, warehouses, in premises for electrical installations and at many other objects. Often their installation is a mandatory requirement, enshrined in law.

Extinguishing powders and foams quickly absorb a large amount of heat, quickly cooling a burning surface. In addition, they form a thin film that prevents the access of oxygen to the fire. The disadvantage of fire extinguishing installations using these materials is their short shelf life.

- Non-combustible gases. Non-combustible gas fire extinguishing systems supplied by our company have undeniable advantages. These substances (carbon dioxide, nitrogen and others) do not affect materials and property, since their influence is limited to the displacement of oxygen from the combustion zone. In addition, they do not freeze at low temperatures and easily erode after a fire. They also have a disadvantage, and it must be taken into account. It consists in the need for rapid evacuation of people before extinguishing, as oxygen "overlaps" not only with fire, but also with people.

Let's try to separate such settings into different groups, and we will understand the pros and cons of each group. How automatic fire extinguishing systems are classified is indicated in the following diagram.

|

What substance does a fire extinguish |

Design |

Fire extinguishing method |

Method for starting installations |

|||||||||

|

Sprinkler |

By volume |

Manual start |

||||||||||

|

Deluge |

By area |

Automatic start |

||||||||||

|

Modular |

Locally |

Combined Start Method |

||||||||||

|

Powder |

Aggregate |

|||||||||||

|

Aerosol spray |

||||||||||||

We will deal with each type of extinguishing agent in more detail.

Fire extinguishing installation using water and foam

Such fire extinguishing systems are sprinkler and deluge, it depends on that. what sprinklers are used in them. Drenchers are ordinary irrigators that have a directed action.

A sprinkler differs from a drencher in that it contains a glass flask that prevents the extinguishing agent from escaping. It also contains a special alcohol impurity. If the flask heats up and reaches a certain temperature, it begins to break down, since the alcohol mixture in it expands, and thereby water or foam gets free access and goes outside.

In addition, sprinkler equipment is classified based on what the distribution pipelines are filled with, as well as those that are responsible for power. So they are water-filled, air and water-air.

Air and water-air systems are used when it is considered possible that the temperature will drop in the area where the pipelines are laid, and also so that ice would not form on their inside.

The difference between foam fire extinguishing and water fire is that it has a foaming agent that is connected to the piping system. Foaming agents are of the following types:

- In the form of metering pumps that supply a foaming agent to the hole in the pipeline;

- In the form of automatic dispensers, which contain a Venturi tube and a plunger reducer (if the flow of water resources increases, then the pressure in the tube increases, and the reducer begins to supply an additional amount of foam);

- In the form of ejector-type foamers;

- In the form of metering tanks that take advantage of the pressure drop that the venturi creates.

As its advantage, it can be noted that water fire extinguishing is safe for humans, and its fire extinguishing substance is available in unlimited quantities, unless of course the system is connected to an external water supply network.

At the same time, some restrictions must be taken into account: fire extinguishing installations must be supplied with water according to the first category of reliability. This means that there must be two different sources from which water must flow to the pumping stations. If it is impossible to organize such an input, then it is necessary to provide a storage facility where the extinguishing agent will be contained, and in this case water.

The main disadvantage of the water and foam system is that the equipment and structures are quite bulky, in addition, it is necessary to carry out welding work during the installation of pipes. In addition, it is necessary to design and install a booster pump station if the necessary pressure is not available at the equipment inlet.

But still, it is hardly possible to find an alternative to this method of extinguishing fires if the system needs to be installed on a large object, such as, for example, a multifunctional center, a hypermarket, or in a building where a large number of visitors are constantly present.

It is worth talking about this form especially. It has all the advantages of water fire extinguishing, but some of the disadvantages are absent. So, if a normal sprinkler sprinkler is triggered, then droplets with a diameter of up to two millimeters and with a fairly significant mass are formed.

This leads to the fact that drops quickly fall down and only one third of them somehow contributes to extinguishing the fire. Waters why so much water is spent. If the fire is extinguished using finely atomized water, then the droplets have a diameter of not more than one tenth of a millimeter. They fall quite slowly, which leads to the formation of the so-called “water fog”. Most of the water resources are spent on cooling structures and extinguishing a fire.

This leads to the fact that water is consumed three times less, which will allow not to install expensive pumping equipment, reduce the diameter of the supply and distribution piping. Such a system will also help prevent the unpleasant consequences that occur if a large amount of water is used. Such consequences may be corrosion, damaged equipment or material values.

The fire extinguishing system in which the finely atomized water is used can be modular and centralized (aggregate).

If the equipment needs to be installed in a small separate room, then it is better to use a modular system, which consists of a vessel containing fire extinguishing agent), a cylinder in which the working gas is located, to form a gas-liquid mixture and a distribution pipe that has nozzles sprinklers.

Such equipment is installed in rooms with an area of \u200b\u200bmore than a thousand square meters. Aggregate units consist of separate sections, which in turn consist of several modules. They do not have starting cylinders containing working gas. The modules receive it from switchgears through standard carbon dioxide fire fighting batteries.

The advantage of such a system lies in the fact that it is not connected to power sources, since this installation operates on the basis of the hydraulic principle.

The disadvantages include the fact that it may cost less than similar gas plants, but still its cost is much more than the price of a powder system. In addition, if you use finely dispersed water over a large area, then this will not be an economical means.

Designing such installations is also not so easy, it causes certain difficulties. Since there is no full regulatory regulatory documentation, the technical conditions are developed for any facility and agreed with representatives of the Ministry of Emergency Situations.

A similar system is installed when the powder, water or foam used in other systems can harm equipment located on the territory of the fire.

Such systems have the advantage that they completely lack side effects on the property located there, unless of course the ventilation system is correctly designed.

Extinguishing agent is removed from the fire area very soon. Gas extinguishing is based on the following principle: the oxygen concentration decreases, since non-combustible gas begins to flow into this area. If this gas is liquefied, then leaving the cylinders it leads to a decrease in temperature. A gas fire extinguishing system differs from others in that it does not freeze, nor is it afraid of heat. It can work properly at minus forty and plus fifty.

The disadvantage of such systems is that the extinguishing gases used can be toxic, which means that before using them, people who are in a dangerous area must be evacuated beforehand, and the facility itself must be equipped with self-defense equipment (self-rescue kits, gas masks).

In addition, such a system must necessarily have equipment that would prevent the system from turning on if the doors are open. Along with this, it is necessary to provide special openings that will be used to relieve excess pressure in the protected area when a gas extinguishing agent is supplied. And the main drawback is its overpriced. To protect a small area you need to have a large amount of gas that is stored in cylinders or an isothermal tank.

Basically, gas fire extinguishing is used to secure a relatively small room with a high degree of tightness, which contains expensive high-tech equipment or other property that can be damaged by other extinguishing agents.

Depending on how the extinguishing agent is stored, powder extinguishing is modular and centralized. Modular powder fire extinguishing has become widespread. This is due to its certain undeniable advantages. Such a system consists of vessels having a different shape, which contain fire extinguishing powder and gas generating elements. This makes it possible to install such a system in almost any room. They can be installed in an enclosed space - a cable structure, behind a pseudo-structure, in a cabinet containing equipment, as well as in other similar places.

If the gas-generating mixture is heated to a critical temperature at which the system is triggered, then a propellant begins to be released intensively in the module. This leads to the disclosure of the shell of the modules, or there is a flow of powder using a nozzle. The module works in the same way if an electrical signal is supplied, if the system has an electric start. Standing out, the powder leads to the formation of a dusty air mixture. This mixture gradually drops, and thereby oxygen stops flowing into the fire area, and this leads to its blocking.

Another advantage of such a system is that it allows you to put out almost all types of fires, even if it concerns high-voltage electrical equipment.

This does not apply only to those materials that can burn in an oxygen-free environment. Another advantage is the price of powder fire extinguishing systems. They stand below all other installations.

Now turn to the disadvantages of powder plants. First of all, they are dangerous to humans, because if a large amount of powder gets into the respiratory system, then this can lead to suffocation. And also, if the modules work, then maybe because of the powder cloud nothing will be visible. That is why such installations are rarely used in a public place, or in a room where many people are constantly present. If the powder is in the modules for a long time, then it starts to deteriorate, which is why their shelf life is limited. In addition, if the installation is triggered, then after extinguishing the fire, it may be difficult to remove the fine powder.

Such a system is based on the use of fine powder. When some solid chemical compounds are burned, then an aerosol is formed, that is, when these substances are burned, this leads to the formation of a jet, which includes a hot mixture of gases and trace elements.

Filling all the free space, they contribute to the extinction of the flame. That is why such installations are not used in the room where explosive substances are located. If aerosol fire extinguishing is triggered, then the temperature rises, the pressure in the gas medium and the visibility sharply decreases. That is why people urgently need to leave the premises before the generator turns on.

However, it should be noted that the effect of aerosol on the human body is not harmful, while it has great fire extinguishing ability.

How various types of fire extinguishing systems are applied

|

Extinguishing agent form |

How is a fire extinguished |

Where can I apply the installation |

Where you can not apply the installation |

|

Water |

Superficial, volumetric (if fire extinguishing using finely dispersed water is used) |

To eliminate class A and B fires. Install in warehouses, supermarkets, hotels, rooms where combustible natural and synthetic resins, plastic and so on are produced. |

In rooms where substances are stored that release heat, combustible or toxic gas during interaction with water. This applies to certain metals and organometallic compounds, carbides and hydrides of metals, hot coal and iron. And also, sprinkler and deluge systems are not used to extinguish high-voltage electrical equipment. |

|

Foam |

Volumetric, surface and local |

Most often used in the petrochemical industry to extinguish a fire in which flammable and combustible liquids burn. There are also other areas of application: a tank of fuel or oil products, which are located both in the building and outside, in hangars, in warehouses where solvents, alcohols are stored, in the holds of ships and so on. |

This installation should not be used if substances are ignited which, when interacting with the foam, toxins are released. |

|

Gas |

Volumetric fire extinguishing method |

To eliminate fires of varying degrees of danger if high-voltage electrical equipment ignites. Their main advantage is that they can be said to not cause damage to the object that they protect. As a rule, they are installed in a computer center, in libraries, archives, museums, money vaults, some warehouses and so on. |

|

|

Powder |

Apply when a flammable liquid is spilled or gas leaks from equipment that is located outdoors. In addition, they are used in oil and pumping facilities, aircraft hangars, and so on. Effectively extinguish a fire in electrical installations where there is high voltage. |

It should not be used if a room is burnt out, in which there are materials that tend to burn even in an oxygen-free environment, which spontaneously ignite or smolder in a substance (a warehouse with sawdust, cotton, grass flour, foam rubber ...), or metals such as sodium, potassium, magnesium, titanium ... |

|

|

Aerosol spray |

Volumetric local and surface |

To eliminate fires of the first and second degree of complexity. Typically, such a system is used if electrical equipment and other energy facilities are ignited, and also to protect vehicles, oil farms, transport compartments of ships and so on. |

Do not completely extinguish a fire if fibrous, porous and other combustible materials that are capable of spontaneous combustion and smolder in a layer burn; technical substances, as well as mixtures thereof, polymeric materials that are able to smolder and burn in an oxygen-free environment; metal hydrides; metal powders |

And finally, it should be noted that in accordance with the regulations, in each specific object, the licensed design organization decides which fire extinguishing system to install, how to extinguish a fire, and what kind of fire extinguishing agent to use. In this case, fire hazard and chemical properties of substances that are produced, stored and applied are taken into account. It is also necessary to take into account what features the protected equipment and building structures have.

And yet, you do not need to make the final choice of fire extinguishing systems, without taking into account how much the installation of fire equipment will cost. It is also necessary to take into account how compatible engineering systems of rooms and fire safety systems are. And of course, you don’t need to bypass the calculations of how much maintenance and routine maintenance will cost, which often cost more than installing the entire system.

Control devices and equipment that are part of fire extinguishing installations must have a certificate of conformity, meet the requirements of standards and regulatory and technical documents in force in the Russian Federation, and not have manufacturing or other defects.

Fire extinguishing installations should be operated in automatic mode.

The decision to transfer the automatic fire extinguishing installation to the manual start mode should be agreed with the local fire supervision authorities on the ground.

It is allowed to switch from automatic control to manual start only during scheduled preventive or other works that are not related to the need to shut down the entire installation.

In the latter case, the facility manager is required to take measures for additional fire protection to compensate for the temporary absence of automatic fire fighting.

Elements and components of fire extinguishing installations should be painted in colors that meet the requirements of GOST:

-fire locking devices, manual start devices, start buttons- in red;

-pipelines filled with water in standby mode- in green;

-pipelines filled with air in standby mode- in blue;

-pipelines filled with water or air- in green and blue colors with alternating colored fields 2 meters wide;

- pipelines filled with carbon dioxide or nitrogen - in yellow, freon - in brown.

Fire extinguishing installations during commissioning after repair, partial or complete replacement of equipment must undergo 72-hour standby monitoring.

The premises of the pumping station, automatic water feeder and control units must have working emergency lighting, be constantly closed.

The keys to these rooms must be located at the service (one set) and operational (duty) (second set) personnel.

In the premises protected by the automatic fire extinguishing installation, instructions should be posted on the actions of the personnel working in them in case of switching on the warning equipment, as well as in the case of an incorrect start or false (accidental) operation of the installation.

It is forbidden to turn off the automatic lock of the supply and exhaust ventilation and technological equipment.

Cylinders and containers of fire extinguishing installations when exceeding the weight loss or lowering the pressure in them more than 10% are subject to recharge or recharge.

Water and foam fire extinguishing systems

In places where there is a risk of mechanical damage, sprinklers should be protected with reliable fences that do not affect the map of irrigation and heat flux distribution.

Wires and cables laid to the sprinklers with remote electrical start-up must meet the requirements of the PUE.

Within each distribution pipeline (one section), sprinklers with outlet openings of the same diameter should be installed.

Sprinklers should be kept clean at all times.

During the repair work in the protected premises, sprinklers should be protected from plaster, paint and whitewash.

After the repair of the premises is completed, the protective devices must be removed.

The supply of irrigators at the facility (enterprise) should be at least 10% for each type of irrigators installed among distribution pipelines, for their timely replacement during operation.

Forbidden:

-Install instead of opened or faulty sprinklers, install plugs and plugs, as well as install sprinklers with a different (except for the design and estimate documentation) melting point of the lock;

- store materials at a distance of less than 0.6 meters from the sprinklers.

Pipelines in rooms with a chemically active or aggressive environment must be protected with acid-resistant paint.

Forbidden:

- the use of pipelines of fire extinguishing installations for suspension or fastening of any equipment; -connection of production equipment or sanitary equipment to the supply pipelines of the fire extinguishing installation;

-installation of valves and flange connections on the feed and distribution pipelines;

-use of internal fire hydrants installed on the splinker network for purposes other than extinguishing a fire; - the use of compressors is not for its intended purpose.

Each control unit must have a functional strapping diagram, and in each direction a plate indicating operating pressures, the names of the protected premises, the type and number of sprinklers in each section of the system, the position (state) of the shut-off elements in standby mode.

Tanks for storing an untouchable water supply for fire fighting must be equipped with devices that exclude water consumption for other needs.

At the enterprise for foam fire extinguishing installations, a 100% reserve stock of the foaming agent should be provided.

The room of the pumping station should be provided with telephone communication with the control room.

At the entrance to the premises of the pumping station, the sign “Fire extinguishing station” should be hung up, and a light board with a similar inscription should constantly function.

In the room of the pumping station, clearly and neatly executed piping schemes of the pumping station and a schematic diagram of the fire fighting installation should be hung out.

All indicating measuring instruments must have inscriptions on operating pressures and the permissible limits of their measurements.

At the control room (facility) must be around the clock duty personnel in an amount of at least 2 people.

The control room should be provided with direct telephone communication with the premises of the pumping station, main water supply, urban telephone communication, working electric lights (at least 3 pieces), as well as personal protective equipment.

A light and sound alarm should be provided in the control room about the operation of fire extinguishing installations, as well as about any malfunctions that arose in the system

In the control room should be posted instructions on the actions of the duty personnel upon receipt of signals about the operation of the installation.

Gas extinguishing installations

The requirements for the maintenance of nozzles and sprinklers, as well as pipelines of gas fire extinguishing installations, are similar to the requirements for water and foam fire extinguishing installations.

The gas fire extinguishing installation station during its operation in standby mode must be provided with a 100% reserve of extinguishing agent.

Each switchgear must have a sign indicating the name and location of the protected premises.

The premises of the fire extinguishing station must have first aid kits located in specially equipped cabinets, as well as insulating personal protective equipment (insulating gas masks).

The premises of the fire extinguishing station should be provided with direct telephone communication with the control room. At the entrance to the premises of the fire extinguishing station should be hung a sign and a permanently functioning sign “Fire extinguishing station”.

The premises of the fire extinguishing station should have clear and neatly executed piping schemes and a schematic diagram of the installation.

Air ducts must be provided with pressurized valves that close automatically when the fire extinguishing system is triggered, to prevent the extinguishing agent from entering the rooms adjacent to the protected one.

For persons working in a protected room, instructions should be developed on the procedure for their actions and evacuation upon receipt of a warning signal about the operation of the fire extinguishing installation.

The operation and maintenance of volumetric aerosol fire extinguishing systems of the CAT type should be carried out in accordance with the requirements of NPB 21-94, other applicable scientific and technical standards.

Premises for which volumetric fire extinguishing installations are provided should have hermetically sealed doors.

Manual start devices for volumetric fire extinguishing installations (except for local ones) are located outside the protected premises at the evacuation exits with free access to them.

Manual start devices for fire extinguishing installations, as well as manual fire detectors for fire alarm systems, must be protected against damage, unauthorized activation and sealed.

The requirements for control rooms are similar to the requirements for control rooms of water and foam fire extinguishing installations.

All indicating devices must have inscriptions on operating pressures, as well as on the operating position of valves, gate valves, etc.

Powder fire extinguishing installations (UPT)

The technical means of UPT must comply with design decisions, technical documentation of manufacturers and mark certificates of conformity.

The starter must have one of the following types of start-up depending on the type of system:

-pneumatic;

cable (manual);

-electric;

-combined.