Development of a fire protection system for buildings for various purposes. Fire protection systems. Automatic fire alarm and fire extinguishing installations. Norms and design rules

We bring to your attention the answers to the questions in accordance with GOST R 53325-2009 and the Code of Practice (SP 5.13130.2009), which are given by the specialists of the Federal State Institution VNIIPO EMERCOM of Russia Vladimir Leonidovich Zdor, deputy head of the Research Center for Fire and Rescue Equipment, and Andrei Arkadyevich Kosachev, deputy Head of the Research Center for Fire Prevention and Fire Emergency Prevention.

QUESTIONS AND ANSWERS

GOST R 53325-2009

section 4.2.5.5. “... If it is possible to externally switch the technical characteristics of fire detectors, the following requirements must be met: - each value of the established technical characteristic must correspond to a certain marking on the fire detector, or this value should be available for monitoring with the control panel;

“After installing the fire detector, there should be no direct access to the means of adjustment.”

Question: If a non-conventional smoke detector has 3 sensitivity levels programmable from an external remote control, in what form should this be reflected on the detector marking?

Answer: Marking of the detector, if it is possible to adjust its sensitivity, is applied at the location of the adjustment body. If the detector is controlled from an external control panel, then information on the set value must be obtained either from the control panel or from service equipment (the same external control panel).

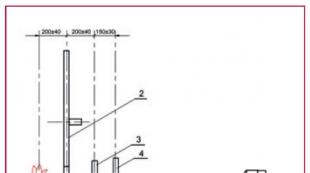

clause 4.9.1.5. "... The components of the IPDL (the receiver and transmitter of the two-component IPDL and the transceiver of the one-component IPDL) must have adjustment devices that allow you to change the angle of inclination of the axis of the optical beam and the diaphragm of the directivity of the IPDL in the vertical and horizontal planes."

Question: Most likely, was it referring to the “IPDL radiation pattern”?

Answer: Of course, there is a typo in the text. You should read the "radiation pattern".

clause 4.9.3. "Methods of certification testing of smoke detectors optical-electronic linear." 4.9.3.1.

“... Determination of the threshold of operation of the IPDL and the interruption of the optical beam IPDL is as follows. Using a set of optical attenuators that are installed as close to the receiver as possible to minimize the effects of scattering in the attenuators, the detector threshold is determined, sequentially increasing the attenuation of the optical beam. If after installation of the attenuator for a period of not more than 10 s the IPDL generates a “Fire” signal, then the detector threshold value is fixed. Determine once the threshold value of each detector.

IPDL put on standby. A light-tight partition for a time (1.0 ± 0.1 s) covers the optical beam. Control the preservation of the IPDL standby mode. Then, an optical beam is blocked by an optical barrier for a time of 2.0 2,5 2.5 s. Control the issuance of IPDL signal "Failure".

IPDLs are considered to have passed the test if the measured response thresholds satisfy the requirements specified in 4.9.1.1, the ratio of the maximum and minimum response thresholds does not exceed 1.6, IPDL retained the standby mode when the optical beam was blocked for a time (1.0 ± 0.1) s and issued the notice “Failure” when the optical beam was blocked for a period of time (2.0 ± 0.1) s ”.

Question: Why is the requirement “more than 2 s” specified in clause 4.9.1.10 of this document, and here is the range (2.0 ± 0.1) s?

Answer: There was a mistake in the layout of the document. The time value indicated in paragraph 3 of paragraph ((2.0 ± 0.1) s) should be read as in paragraph 2 ((2.0 ± 2.5) s).

paragraph 4.10.1.2. “... In terms of sensitivity, aspiration detectors should be divided into three classes: - class A - high sensitivity (less than 0.035 dB / m);

- class B - increased sensitivity (in the range from 0.035 to 0.088 dB / m);

- class C - standard sensitivity (more than 0.088 dB / m ").

Question: Should we correctly understand that in this paragraph we mean the sensitivity of the detector processing unit itself, and not the sensitivity from the verst?

Answer: The sensitivity of the suction detector cannot be considered separately: the sensitivity of the hole and the sensitivity of the processing unit, since this detector is a single technical means. It should be noted that smoky air can enter the processing unit from more than one hole.

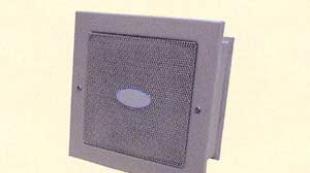

clause 6.2.5.2. "... Fire alarms should not have external volume controls."

Question: What are the reasons for this requirement?

Answer: The volume level created by voice annunciators is regulated by the requirements of clause 6.2.1.9. The presence of the volume control, available for unauthorized access, nullifies the fulfillment of the requirements of this paragraph.

clause 7.1.14. "... A control panel, interacting with fire detectors via a radio channel, must receive and process the transmitted value of the controlled fire factor, analyze the dynamics of this factor and decide on a fire or a malfunction of the detector."

Question: Does this mean that all radio channel fire detectors must be analog?

Answer: The requirement applies to the control panel, and not to the announcers.

SP 5.13130.20099

paragraph 13.2. "Requirements for the organization of control zones fire alarm».

paragraph 13.2.1. “... One fire alarm loop with fire detectors (one pipe for air sampling in the case of an aspiration detector) that do not have an address, it is allowed to equip a control zone, including:

- - premises located on no more than two interconnected floors, with a total area of \u200b\u200b300 m2 or less;

- up to ten isolated and adjacent rooms with a total area of \u200b\u200bnot more than 1600 m2, located on one floor of the building, while the isolated rooms should have access to a common corridor, hall, lobby, etc .;

- up to twenty isolated and adjacent rooms with a total area of \u200b\u200bnot more than 1600 m2 located on one floor of the building, while the isolated rooms must have access to a common corridor, hall, lobby, etc., if there is an external light signaling about the operation of fire detectors above Entrance to each controlled room;

- Conventional fire alarm loops should integrate the premises in accordance with their division into protection zones. In addition, the fire alarm loops must unite the premises in such a way that the time for establishing the place of a fire by the on-duty personnel during semi-automatic control does not exceed 1/5 of the time after which safe evacuation of people and extinguishing of the fire can be realized. If the specified time exceeds the given value, the control should be automatic.

The maximum number of non-addressable fire detectors powered by an alarm loop should ensure the registration of all notifications provided for in the applicable control panel. ”

Question: The maximum number of rooms controlled by one pipe of the suction detector?

Answer: With one aspiration detector, you can protect as many rooms located in accordance with clause 13.2.1 as with one addressless wire loop alarm with fire point detectors, taking into account the area protected by one aspiration detector.

clause 13.9.4. “... When installing the pipes of aspiration smoke detectors in rooms with a width of less than 3 m, or under a raised floor, or over a raised ceiling and in other spaces with a height of less than 1.7 m, the distances between the air intake pipes and the wall specified in table 13.6 may be increased by 1, 5 times. "

Question: Does this item also allow a 1.5-fold increase in the distance between the air inlets in the pipes?

Answer: The location of the air sampling openings, as well as their size, in the suction detector is determined by technical specifications these detectors, taking into account the aerodynamics of the air flow in the pipes and near the air intake openings. As a rule, information about this is calculated using a mathematical apparatus developed by the manufacturer of the suction detector.

GOST R 53325-2009 and SP 5.13130.2009: contradictions

1. The immunity of technical equipment to electromagnetic interference.

To eliminate equipment failures, including false alarms fire protection, regarding electromagnetic compatibility, in our country there is a rather serious regulatory framework. On the other hand, in the Code of Rules of the Joint Venture 5.13130.2009, its developers remained at their old positions: paragraph 13.14.2. “... Fire alarm control panels, fire control devices and other equipment operating in installations and systems fire automatics"must be resistant to electromagnetic interference with a degree of rigidity not lower than the second according to GOST R 53325".

Question: Do the detectors relate to the above “other equipment”?

(In all European countries, the standard EN 50130-4-95 applies. This standard establishes the requirements for electromagnetic compatibility for absolutely all safety systems (OPS, ACS, SOT, SOUE, ISO), including fire alarms and automation).

Question: Is the lower limit of compliance with the requirements of this standard of technical safety equipment our Russian 3rd degree of rigidity?

Answer: In the National Standard GOST R 51699-2000 “Electromagnetic compatibility. Immunity to technical interference burglar alarm. Requirements and Test Methods harmonization with the aforementioned EN 50130-4-95 was carried out, which once again proves the inappropriateness of using technical means in the current electromagnetic environment with a 2nd degree of rigidity as the main sources of failure in systems.

Question: In accordance with what recommendations, the required degree of rigidity can and should be chosen in order to fulfill the requirements of clause 17.3 of SP5.13130.2009 “Technical means of fire automatics must have parameters and versions that ensure safe and normal functioning under the influence of the environment of their placement”?

Answer: Immunity of technical equipment (TS) to electromagnetic interference (EMF).

To increase the protection of the vehicle from EMF, it is necessary to complicate it as an electric one. circuit diagram, and the design of the vehicle, which leads to their appreciation. There are objects where the level of EMF is very small. The use of vehicles with a high degree of protection against electromagnetic fields at such facilities becomes economically disadvantageous. When the designer of the vehicle chooses for a particular object, the degree of rigidity of the vehicle performance by EMC should be selected taking into account the magnitude of the electromagnetic field at the facility according to generally accepted methods.

2. Fire tests of fire detectors.

Questions:

a) Why, when transferring the requirements of GOST R 50898 “Fire detectors. Fire tests ”in appendix N GOST R 53325“ Fire fighting equipment. Technical means of fire automatics. General technical requirements. Test methods ”from the order of conducting fire tests were removed the graphs of the dependence of optical density on the concentration of combustion products and optical density of the medium on time (Fig. L1-L.12) for test fires? Lack of control over the development of test fires will allow accredited testing laboratories to make incorrect measurements, which may discredit the tests themselves?

b) Why did the placement order of verified detectors disappear from the fire test procedure?

c) In clause 13.1.1 of the Code of Rules of the Joint Venture

5.13130.2009 stipulates that: "... The choice of the type of point smoke detector is recommended in accordance with its sensitivity to various types of fumes." Moreover, in the order of conducting fire tests in Appendix N GOST R 53325, the classification of detectors by sensitivity to test fires is removed. Is it justified? There was a good selection technique.

Answer: The simplification of the process of conducting fire tests in comparison with the provisions of GOST R 50898 was made in order to reduce their cost. As practice has shown, the test results in Appendix N GOST R 53325 and GOST R 50898 have slight differences and do not significantly affect the content of the conclusions of the tests.

3. Fire detectors, installation rules.

In SP 5.13130.2009 Appendix P, a table is given with distances from the upper overlap point to the measuring element of the detector at different angles floor slope and room height. The reference to Appendix P is given in paragraph 13.3.4: “Point fire detectors should be installed under the ceiling. If it is not possible to install the detectors directly on the floor, they can be installed on cables, as well as on walls, columns and other supporting building structures. When installing point detectors on walls, they should be placed at a distance of at least 0.5 m from the corner and at a distance from the floor in accordance with Appendix P. The distance from the top floor point to the detector at the installation site and depending on the height of the room and the shape of the floor can be determined in accordance with Appendix P or at other heights, if the detection time is sufficient to perform fire protection tasks in accordance with GOST 12.1.004, which must be confirmed by calculation ... ".

Questions:

Answer: Point fire detectors should include point heat, smoke and gas fire detectors.

b) What distances from overlapping to the measuring element of the detector are recommended when installing detectors near the ridge and near the inclined ceiling in the middle of the room? In which case is it recommended to adhere to minimum distances, and in which maximum - according to Appendix P?

Answer: In places where the convective flow “flows”, for example, under the “ridge”, the distance from the floor is selected large according to Appendix P.

c) For slope angles of up to 15 angles. hail., and consequently, for horizontal floors, the minimum distances from the floor to the measuring element of the detector, recommended in Appendix P, are from 30 to 150 mm, depending on the height of the room. In this regard, is it recommended to install detectors directly on the ceiling using brackets to ensure the recommendations given in Appendix P?

d) In which document is the methodology for calculating the implementation of fire protection tasks in accordance with GOST 12.1.004 when installing detectors at different heights other than those recommended in Appendix P?

e) How should the deviation from the requirements of clause 13.5.1 of SP5 regarding the height of the IDPL installation be confirmed, and where is the methodology for carrying out the calculations indicated in the note?

Answer (g, d): The methodology for determining the time of occurrence of the limit values \u200b\u200bof dangerous fire factors that are dangerous for a person at the level of his head is given in Appendix 2 of GOST 12.1.004.

The time for fire detection by fire detectors is carried out according to the same method, taking into account the height of their location and the values \u200b\u200bof the fire hazard factors at which the detectors fire.

f) Upon a detailed review of the requirements of clause 13.3.8 of SP5, there are obvious contradictions in the contents of tables 13.1 and 13.2. So, if there are linear beams on the ceiling with a room height of up to 3 m, the distance between the detectors should not exceed 2.3 m. The presence of a cellular structure of ceiling beams at the same room height implies large distances between the detectors, although the conditions for smoke localization between the beams require in this case, the same or more stringent requirements for the distances between the PI?

Answer: If the size of the floor area formed by the beams is less than the area of \u200b\u200bprotection provided by one fire detector, use table 13.1.

At the same time, the distance between the detectors located across the beams decreases due to poor spreading of convective flow under the ceiling.

In the presence of a cellular structure, spreading is better, due to the fact that small cells fill with warm air faster than large compartments linear arrangement beams. Therefore, detectors are installed less frequently.

SP 5.13130.2009. The requirements for the installation of point smoke and heat detectors refer to paragraph 13.3.7:

paragraph 13.4.1. “... The area controlled by one point smoke detector, as well as the maximum distance between the detectors, detector and the wall, with the exception of cases specified in 13.3.7, must be determined according to table 13.3, but not exceeding the values \u200b\u200bspecified in the technical conditions and passports on detectors of specific types.

paragraph 13.6.1. The area controlled by one point heat detector, as well as the maximum distance between the detectors, detector and the wall, with the exception of cases specified in clause 13.3.7, must be determined according to table 13.5, but not exceeding the values \u200b\u200bspecified in the technical conditions and passports on detectors. "

However, in clause 13.3.7, no cases are stipulated:

paragraph 13.3.7. The distances between the detectors, as well as between the wall and the detectors, shown in tables 13.3 and 13.5, can be changed within the area shown in tables 13.3 and 13.5.

Question: Does it follow that when arranging the detectors, only the average area protected by the fire detector can be taken into account, not observing the maximum permissible distances between the detectors and from the detector to the wall?

Answer: When arranging point fire detectors, the area protected by one detector can be taken into account, taking into account the nature of the spreading of convective flow under the ceiling.

paragraph 13.3.10 "... When installing point smoke detectors in rooms with a width of less than 3 m or under a raised floor or over a raised ceiling and in other spaces with a height of less than 1.7 m, the distances between the detectors indicated in Table 13.3 may be increased by 1.5 times."

Questions:

a) Why is it said that it is allowed to increase only the distance between the detectors, but does not mention the possibility of increasing the distance from the detector to the wall?

Answer: Since, due to the restriction of convective flow spreading by wall structures and overlapping, the flow is directed along a limited space, the distance between point detectors is increased only along a narrow space.

b) How does the requirement of clause 13.3.10 relate to the content of clause 13.3.7, where in all cases it is allowed to provide only the average area protected by the fire detector, not observing the maximum permissible distances between the detectors and from the detector to the wall?

Answer: For narrow spaces of no more than 3 m in size, smoke spreading is still difficult.

Since clause 13.3.7 speaks of a possible change in distances within the protection area provided by one detector, clause 13.3.10, in addition to clause 13.3.7, speaks of the permissibility of increasing the distance by only 1.5 times for such zones .

clause 13.3.3. “... It is allowed to install one automatic fire detector in the protected room or in the allocated parts of the room if the conditions are fulfilled at the same time:

... c) identification of the faulty detector by means of a light indication and the possibility of replacing it by the duty personnel for a set time determined in accordance with Appendix 0 ... are provided. ”

Questions:

a) Does SP 5.13130.2009 allow 13.3.3 subparagraph c) the identification of a defective detector using the light indication on the control panel or on the control panel PPKP / PPU?

Answer: Clause 13.3.3 allows for any means of determining the malfunction of detectors and its location in order to replace it.

b) How should the time be determined for the detection of a malfunction and the replacement of the detector? Are there any calculation methods for this time for various types objects?

Answer: The operation of facilities without a fire safety system, where such a system is required, is not allowed.

Since the failure of this system, the following options are possible:

1) the technological process is suspended until the system is restored, taking into account clause 02 of Appendix 0;

2) the functions of the system are transferred to the responsible personnel if the personnel are able to replace the functions of the system. It depends on the dynamics of the fire, the volume of functions performed, etc.

3) a reserve is introduced. The reserve (“cold” can be entered manually (replacement) by duty personnel or automatically if there are no duplicate detectors (“hot” reserve) taking into account clause O1 of Appendix O.

The operational parameters of the system should be given in the design documentation for the system, depending on the parameters and significance of the object of protection. At the same time, the system recovery time given in the design documentation should not exceed the permissible time for the suspension of the technological process or the time for transferring functions to the duty personnel.

paragraph 14.3. “... For the formation of the control team according to 14.1, in the protected room or protected zone must be at least:

- three fire detectors when they are included in the cables of two-threshold devices or in three independent radial loops of single-threshold devices;

- four fire detectors when they are included in two loops of single-threshold devices, two detectors in each loop;

- two fire detectors that meet the requirements of clause 13.3.3 (a, b, c), switched on according to the logic circuit “I”, subject to the timely replacement of a faulty detector;

- two fire detectors, switched on according to the logic OR, if the detectors provide increased reliability of the fire signal. "

Questions:

a) How to determine the timeliness of replacing a faulty detector? What time should be considered necessary and sufficient to replace the detector? Does this mean Appendix O in this case?

Answer: The allowable time for introducing a reserve manually is determined on the basis of the normative level of people's safety in case of fire, the accepted level of material losses in case of fire, as well as the likelihood of a fire at an object of this type. This time interval is limited by the condition that the probability of exposure to hazardous fire factors on people during a fire does not exceed the standard. For estimates of this time, the methodology of Appendix 2 of GOST 12.1.004 can be used. Estimates of material losses - according to the methodology of Appendix 4 GOST 12.1.004.

b) What should be understood by the increased reliability of a fire signal? Does this mean taking into account the recommendations set out in Appendix P? Or something different?

Answer: In the near future, requirements for mandatory parameters of technical equipment for fire automatics will be introduced, as well as methods for checking them during tests, one of which is the reliability of the fire signal.

The technical means using the methods given in Appendix R, when tested for factors other than fire, have a higher reliability of the fire signal compared to conventional detectors, which are turned on according to the logic circuit “I” to increase the reliability.

4. Alert

SP 5.13130.2009 p. 13.3.3. It is allowed to install one automatic fire detector in the protected room or in the allocated parts of the room if the conditions are fulfilled at the same time:

... d) when a fire detector is triggered, a signal is not generated to control fire extinguishing installations or fire warning systems of the 5th type by, as well as other systems whose false functioning can lead to unacceptable material losses or reduce the level of people's safety.

SP 5.13130.2009 p. 14.2. The formation of control signals for warning systems 1, 2, and 3 of type smoke exhaust, engineering equipment controlled by a fire alarm system, and other equipment whose false operation cannot lead to unacceptable material losses or reduce the level of people's safety is allowed when one fire detector, taking into account the recommendations set out in Appendix R. The number of fire detectors in the room is determined in accordance with section 13.

Questions:

Regarding the 4th type of alert, a contradiction is observed. In accordance with clause 13.3.3 g) it is allowed to install ONE detector in the room (naturally, when the remaining conditions of clause 13.3.3 are fulfilled) when generating a control signal for a 4th type alert. In accordance with Section 14, the formation of control signals for a 4th type alert should be made when at least 2 detectors are triggered, which means that their number in the room must be determined in accordance with paragraph 14.3. Which of the conditions should be considered decisive in terms of the number of detectors installed in the room and in terms of the formation of control signals on the 4th type SOUE?

Answer: Sec. 13.3.3, paras. d) does not exclude the installation of one fire detector while fulfilling conditions a), b), c) to generate control signals for fire warning systems and evacuation control (SOUE) type 4 if this does not reduce the level of safety people and unacceptable material losses in case of fire. In this case, fire detectors should protect the entire area of \u200b\u200bthe control zone, be monitored, and the possibility of timely replacement of faulty detectors should be provided.

Improving the reliability of the fire detection system is provided in this case manually.

Insufficient reliability of a fire signal when using one conventional detector can lead to an increase in false alarms. If the level of false alarms does not lead to a decrease in the level of people's safety and unacceptable material losses, such an option for generating a control signal of the 4th type SOUE can be accepted.

In clause 14.2, it is allowed to generate a signal for starting a fuel-and-energy system of 1-3 types from one fire detector with increased reliability of a fire signal without switching on a reserve, i.e. with reduced reliability, also in the event that this does not lead to a decrease in the level of safety of people and unacceptable material losses in the event of a detector failure.

The options for generating the control signal for the SOUE given in clause 13.3.3 and clause 14.2 suggest the rationale for ensuring the level of safety of people and material losses in case of fire when using these options.

Options for generating control signals given in clause 14.1. and 14.3 do not suggest such justifications.

In accordance with paragraph A3 of Appendix A, the design organization independently chooses protection options depending on the technological, structural, space-planning features and parameters of the objects of protection.

Art. 84 p. 7. ... It was determined that the fire warning system should function for the time necessary for evacuation.

Questions:

a) Should sirens, as elements of a warning system, also be resistant to the effects of temperatures characteristic of a developing fire? The same question can be posed in relation to power supplies, as well as control devices.

Answer: The requirement applies to all components of the SOUE depending on where they are located.

b) If the requirements of the article of the law apply only to the communication lines of warning systems, which in this case must be carried out by a fire-resistant cable, should the switching elements, switchboards, etc. be fire-resistant?

Answer: The stability of the technical means of SOUE to the effects of fire factors is ensured by their execution, as well as their placement in structures, premises, areas of premises.

c) If we consider that the fire resistance requirements do not apply to sirens located in the room in which the fire occurs, because people are evacuated from this room first of all, should the conditions for stability of communication lines with sirens installed in different rooms be provided , at destruction of emergency room sirens?

Answer: The stability of the electrical connecting lines must be ensured unconditionally.

d) Which normative documents Is the methodology for assessing the fire resistance of the warning system elements regulated (NPB 248, GOST 53316 or others)?

Answer: Methods for assessing the stability (resistance) from the effects of fire factors are given in NPB 248, GOST R 53316, as well as in Appendix 2 of GOST 12.1.004 (to assess the time to reach the maximum temperature at the location).

e) In which paragraph of the joint venture are the requirements for the duration of the uninterrupted operation of the SOUE? If in clause 4.3 of SP6, a significant amount of previously manufactured and certified equipment does not meet these requirements (increase in alarm time by 3 times compared with the requirements of NPB 77).

Answer: The requirement of clause 4.3 of SP 6.13130.2009 relates to power sources. At the same time, it is possible to limit the provision of power in an alarm mode to 1.3 times of the task.

f) Is it possible to use the control and reception devices with the function of monitoring the control circuits of external sirens as control devices for the control system at the facilities? I mean the control panel that meets the requirements of clause 7.2.2.1 (a-e) of GOST R 53325-2009 presented to the control panel ("Granit-16", "Grand Master", etc.).

Answer: Control panels combining control functions should be classified and certified as combining functions.

Source: "Security Algorithm" No. 5 2009

Questions on the application of SP 5.13130.2009

Question: Should the provisions of clause 13.3.3 of SP 5.13130.2009 be applied to targeted fire detectors?

Answer:

The provisions of clause 13.3.3 are as follows:

“It is allowed to install one automatic fire detector in the protected room or in the allocated parts of the room if the conditions are fulfilled simultaneously:

c) the detection of a defective detector and the possibility of replacing it within a specified time determined in accordance with Appendix O are provided;

Addressable detectors are called addressable because of the ability to determine their location at their address, determined by the address of the control panel. One of the main provisions determining the applicability of clause 13.3.3 is the provision of clauses. b) Addressable detectors must have automatic performance monitoring. In accordance with the provisions of clause 17.4, Note - “Technical means with automatic control of operability are recognized as technical means that have control of components that constitute at least 80% of the failure rate of the technical means.” “Technical means whose reliability in the range of external influences cannot be determined must have automatic health monitoring. If it is impossible to identify a faulty fire detector in the address system, it does not correspond to the provisions of paragraphs. b) In addition, the provision of clause 13.3.3 can be applied only if the provision of clauses in). Estimation of the time required to replace a failed detector with a function of operability monitoring for objects with an established fire probability when installing one detector in accordance with the provisions of clause 13.3.3 of SP 5.13130.2009 is carried out on the basis of the following assumptions in the given sequence.

Answer:

According to SP5.13130.2009, Appendix A, Table 2A, Note 3, GOST R IEC 60332-3-22 is indicated, which describes the method for calculating the combustible mass of cables. You can also see the named methodology in the electronic journal “I am an electrician”. In the journal, the calculation procedure is given with detailed explanations. The amount of combustible mass for different types of cables can be found on the website of the Kolchuginsky cable plant (www.elcable.ru), in the reference section on the reference technical information page. I ask you not to forget that behind the suspended ceilings, in addition to cables, a large number of other communications have been laid, and they can also burn under certain conditions.

Question: In what cases should the APS ceiling space be equipped?

Answer:

The need for equipment of the APS ceiling space is determined in accordance with the provision of clause A4 of Appendix A of SP 5.13130.2009.

Question: Which fire detection system should be preferred for early fire detection?

Answer:

When applying technical means should be guided by the principle of reasonable sufficiency. Technical means must fulfill the objectives of the goal at their lowest price. Early fire detection is primarily associated with the type of fire detector and its location. When choosing a detector type, the prevailing fire factor should be determined. In the absence of experience, you can use the calculation methods for calculating the time of occurrence of the limit values \u200b\u200bof hazardous fire factors (blocking time). The fire factor, the time of occurrence of which is minimally predominant. The same methodology determines the time of fire detection by various technical means. When solving the first target task - ensuring safe evacuation of people, determine the required maximum time for fire detection as the difference between the blocking time and the evacuation time. The resulting time, reduced by at least 20%, is the criterion for choosing the technical means of fire detection. At the same time, the time taken to generate the fire signal by the control panel taking into account its algorithm for processing signals from fire detectors is also taken into account.

Question: In what cases should fire information be transmitted to console 01, incl. over the air?

Answer:

The fire alarm is not used for itself, but for the implementation of the objectives: unconditional protection of human life and health and the protection of material values. In the case when fire departments perform fire extinguishing functions, a fire signal must be transmitted unconditionally and in time, taking into account the location of this unit and its equipment. The choice of transmission method, taking into account local characteristics, rests with the design organization. It should always be remembered that the cost of equipment is an insignificant part of the funds compared with the losses from the fire.

Question: Should only high fire resistance cables be used in fire protection systems?

Answer:

When using cables, one should be guided, as always, by the principle of reasonable sufficiency. Moreover, any decisions require their justification. SP 5.13130.2009 and the new edition of SP 6.13130.2009 require the use of cables that ensure their durability for the duration of tasks in accordance with the purpose of the systems in which they are used. If the contractor is not able to justify the use of the cable, then cables with maximum fire resistance can be used, which is a more expensive solution. As a method for substantiating the use of cables, a method for calculating the time of occurrence of the limit values \u200b\u200bof fire factors dangerous to humans can be used. Instead of temperature limits for a person, temperature limits are set for the cables of a certain type. The time of the onset of the limit value at the height of the cable suspension is determined. The time from the moment of exposure to failure of the cable can be taken equal to zero.

Question:

What can be applied the method of calculating the operating time of a cable of the “ng-LS” type of fire alarm connecting lines that would comply with Article 103 No. 123-FZ of July 22, 2008, will the use of the “ng-LS” cable and the time calculations be sufficient for detecting fire factors by detectors and transmitting an alarm signal to other fire protection systems, including warning.

Answer:

To calculate the operating time of the cable, you can apply the method of calculating the critical duration of the fire at the maximum temperature at the height of the cable according to the method for determining the calculated values \u200b\u200bof fire risk in buildings, structures and structures of various classes of functional fire hazard, order of the Ministry of Emergencies of the Russian Federation No. 382 of June 30, 2009. When choosing a cable type in accordance with the requirements of Art. 103 of Federal Law No. 123-ФЗ dated 06/22/2008, it is necessary to ensure not only the preservation of the operability of wires and cables in a fire for the time necessary to perform tasks by the components of these systems, taking into account the specific location, but also the wires and cables must ensure operability equipment not only in the fire zone, but also in other zones and floors in the event of a fire or high temperatures along the paths of laying the cable line.

Question:

What does clause 13.3.7 of SP 5.13130.2009 mean “Distances between detectors, as well as between a wall and detectors can be changed within the area given in tables 13.3 and 13.5”?

Answer:

The protection areas for heat, smoke and gas point detectors are set in tables 13.3 and 13.5. The convective flow that occurs when a fire occurs in the absence of environmental influences and structures has the shape of a cone. The design features of the room can affect the shape of the convective flow, as well as its spreading under the ceiling. In this case, the values \u200b\u200bof the released heat, smoke and gas are also preserved for the altered form of the spreading flow. In this regard, in paragraph 13.3.10 of SP 5.13130.2009, direct instructions are given to increase the distances between detectors in narrow rooms and ceiling spaces.

Question: How many heat detectors should be installed in the entrance halls of apartments?

Answer:

The amended version of Appendix A of JV 5.13130.2009 does not provide for the installation of thermal fire detectors. The choice of the type of detector is carried out during design, taking into account the characteristics of the protected object. One of the best solutions is to install smoke detectors. In this case, one should proceed from the condition of the earliest formation of a fire signal. The number of detectors is determined in accordance with the provisions of clause 13.3.3, clause 14.1, 14.2, 14.3 of SP 5.13130.2009.

Question: Should the “Exit” indicator always be on or only on in case of fire?

Answer:

The provision of clause 5.2 of SP 3.13130.2009 quite definitely answers the question: "Light annunciators" Exit "... must be switched on for the time people are in them."

Question: How many fire detectors should be installed indoors?

Answer:

The provisions of SP 5.13130.2009, as amended, fully answer the question posed:

"13.3.3 In the protected room or in the allocated parts of the room, it is allowed to install one automatic fire detector if the conditions are fulfilled at the same time:

a) the area of \u200b\u200bthe room is not more than the area protected by the fire detector indicated in the technical documentation for it, and not more than the average area indicated in tables 13.3-13.6;

b) automatic monitoring of the operability of the fire detector under the influence of environmental factors is provided, confirming the fulfillment of its functions, and a notification of serviceability (malfunction) is generated on the control panel;

c) the detection of a defective detector and the possibility of replacing it within a specified time determined in accordance with Appendix O are provided;

d) when the fire detector is triggered, no signal is generated to control fire extinguishing installations or fire warning systems of the 5th type according to SP 3.13130, as well as other systems whose false functioning can lead to unacceptable material losses or reduce the level of people's safety. ”

"14.1 The generation of signals for automatic control of warning systems, fire extinguishing systems, smoke protection equipment, general ventilation, air conditioning, facility engineering equipment, and other actuators of the systems involved in ensuring fire safety should be carried out from two fire detectors connected via logical circuit "And", for the time in accordance with section 17, taking into account the inertia of these systems. In this case, the arrangement of the detectors should be carried out at a distance of no more than half of the standard, determined by tables 13.3 - 13.6, respectively. ”

“14.2 Formation of control signals for warning systems of type 1, 2, 3, 4 according to SP 3.13130.2009, smoke protection equipment, general ventilation and air conditioning, engineering equipment of the facility involved in ensuring the fire safety of the facility, as well as the formation of commands to turn off the power it is allowed to carry out consumers interlocked with fire automatics systems when one fire detector is triggered that satisfies the recommendations set out in Appendix P, provided that the false alarm atyvanie controlled systems may not lead to unacceptable financial losses or a reduction in the level of human security. In this case, at least two detectors are installed in the room (part of the room), connected according to the OR logic. In the case of the use of detectors that satisfy, in addition, the requirements of clause 13.3.3 b), c), one fire detector may be installed in the room (part of the room). ”

“14.3 For the formation of the control team according to 14.1, in the protected room or protected area there must be at least: three fire detectors when they are included in the cables of two-threshold devices or in three independent radial loops of single-threshold devices; four fire detectors when they are included in two loops of single-threshold devices, two detectors in each loop; two fire detectors meeting the requirement 13.3.3 (b, c). ”

When choosing equipment and its operation algorithms, it is necessary to take measures to minimize the likelihood of false positives of these systems. At the same time, a false positive should not lead to a decrease in the safety of people and the loss of material values.

Question: What systems other than fire systems are referred to as "others"?

Answer:

It is known that in addition to fire systems, which include a warning system and fire evacuation control, fire extinguishing system, smoke protection system, a fire signal can be transmitted to control engineering, technological means, which can also be used to ensure fire safety. The sequence control algorithm for all technical means should be developed in the project.

Question: For what purposes are the fire detectors turned on according to the logical circuits “I” and “Or”?

Answer:

When fire detectors are switched on according to the “I” logic scheme, the aim is to increase the reliability of the fire signal. In this case, it is possible to use one detector instead of two full-time ones that implement the reliability enhancement function. Such detectors include detectors called “diagnostic”, “multicriteria”, “parametric”. When fire detectors are switched on according to the Ili logic (duplication), the aim is to increase reliability. In this case, it is possible to use detectors having reliability no less than two duplicated standard ones. When calculating the justification, the hazard level of the facility is taken into account, and if there are justifications for performing the functions of the main purpose, the composition of the fire protection system is evaluated and the requirements for reliability parameters are determined.

Question: Please clarify clause 13.3.11 of SP 5.13130.2009 regarding: is it possible to connect an external optical signaling system (VOOS) to each fire detector installed behind a suspended ceiling, even if there are two or three detectors in the loop and this loop protects one small area 20 m2, a room 4-5 meters high.

Answer:

The requirements of clause 13.3.11 of SP 5.13130.2009 are aimed at providing the ability to quickly detect the location of the triggered detector in the event of a fire or a false alarm. When designing, a variant of the detection method is determined, which should be indicated in the design documentation.

If in your case it is not difficult to determine the location of the triggered detector, then the remote optical indication may not be set.

Question:

I ask you to give an explanation about the remote start of the smoke exhaust system, Art. 85 No. 123-ФЗ " Technical regulations fire safety requirements. ” Is it necessary to install additional start-up elements (buttons) next to the fire alarm IPR for remote manual start of the supply and exhaust smoke ventilation systems of a building to fulfill paragraph 8 of Art. 85 No. 123-FZ? Or IPR connected to a fire alarm can be considered a trigger element, according to paragraph 8 of Art. 85.

Answer:

Signals for switching on smoke protection equipment should be generated by automatic fire alarm devices when automatic and manual fire detectors are triggered.

When implementing the smoke protection control algorithm on the basis of addressable equipment, the loop of which includes addressable manual fire detectors and address executive devices, installation of remote manual start devices at evacuation exits by design may not be provided. In this case, it is enough to install these devices in the room of the duty staff.

If it is necessary to ensure separate switching on of smoke protection equipment from other fire automatics systems, such devices can be installed at evacuation exits and in the premises of duty personnel.

To be continued…

1 area of \u200b\u200buse2. Normative references

3. Terms and definitions

4. General

5. Water and foam fire extinguishing installations

6. Extinguishing fire extinguishing foam

7. Robotic fire complex

8. Settings gas fire

9. Modular type powder fire extinguishing installations

10. Aerosol fire extinguishing installations

11. Autonomous fire extinguishing installations

12. Fire extinguishing equipment control equipment

13. Fire alarm systems

14. The relationship of fire alarm systems with other systems and engineering equipment facilities

15. Power supply for fire alarm systems and fire extinguishing installations

16. Protective grounding and grounding. Safety requirements

17. General provisions taken into account when choosing technical means of fire automatics

Appendix A. List of buildings, structures, premises and equipment to be protected by automatic fire extinguishing installations and automatic fire alarms

Appendix B. Groups of premises (production and technological processes) according to the degree of danger of fire development depending on their functional purpose and fire load of combustible materials

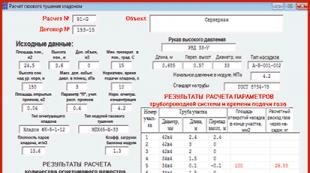

Appendix B. Methodology for calculating AUP parameters for surface fire extinguishing with water and low-foam foam

Appendix D. Methodology for calculating the parameters of fire extinguishing installations with high-foam

Appendix D. Initial data for calculating the mass of gas extinguishing agents

Appendix E. Method for calculating the mass of gas extinguishing agent for gas extinguishing installations during extinguishing by volumetric method

Appendix G. Methods of hydraulic calculation of carbon dioxide fire extinguishing low pressure

Appendix Z. Methodology for calculating the opening area for relieving excess pressure in rooms protected by gas fire extinguishing installations

Appendix I. General Provisions for the Design of Modular Type Powder Fire Extinguishing Installations

Appendix K. Calculation Method automatic installations aerosol fire extinguishing

Appendix L. Methodology for calculating excess pressure when applying a fire extinguishing aerosol to a room

Appendix M. Choosing the types of fire detectors depending on the purpose of the protected premises and the type of fire load

Appendix N. Installation locations of manual fire detectors depending on the purpose of buildings and premises

Appendix A. Determining the set time for detecting and resolving a malfunction

Appendix P. Distances from the upper overlap point to the measuring element of the detector

Appendix R. Fire Alarm Reliability Methods

Bibliography

SET OF RULES

FIRE PROTECTION SYSTEMS

AUTOMATIC FIRE ALARM AND FIRE FIGHTING INSTALLATIONS

NORMS AND DESIGN RULES

SYSTEMS OF FIRE PROTECTION.

AUTOMATIC FIRE-EXTINGUISHING AND ALARM SYSTEMS.

DESIGNING AND REGULATIONS RULES

SP 5.13130.2009

(as amended by Change No. 1, approved by Order of the Ministry of Emergencies of the Russian Federation dated 01.06.2011 No. 274)

Foreword

The goals and principles of standardization in Russian Federation established by the Federal Law of December 27, 2002 N 184-ФЗ “On Technical Regulation”, and the rules for applying the codes of rules - Decree of the Government of the Russian Federation “On the procedure for developing and approving the codes of rules” of November 19, 2008 N 858.

Rule Set Information

- Developed by FSI VNIIPO EMERCOM of Russia.

- Submitted by the Technical Committee for Standardization TC 274 "Fire Safety".

- Approved and enforced by Order of the Ministry of Emergencies of Russia of March 25, 2009 N 175.

- Registered by the Federal Agency for Technical Regulation and Metrology.

- Introduced for the first time.

Information on amendments to this set of rules is published in the annually published information index “National Standards”, and the text of changes and amendments is published in the monthly published information signs “National Standards”. In case of revision (replacement) or cancellation of this set of rules, the corresponding notification will be published in the monthly published information index "National Standards". Relevant information, notification and texts are also posted in the public information system - on the official website of the developer (FGU VNIIPO EMERCOM of Russia) on the Internet.

- Application area

1.1. This set of rules is developed in accordance with Articles 42, 45, 46, 54, 83, 84, 91, 103, 104, 111 - 116 of the Federal Law of July 22, 2008 N 123-ФЗ "Technical Regulation on Fire Safety Requirements", It is a normative document on fire safety in the field of standardization of voluntary use and establishes the norms and rules for the design of automatic fire extinguishing and alarm systems.

1.2. This set of rules applies to the design of automatic fire extinguishing and fire alarm systems for buildings and structures for various purposes, including those being built in areas with special climatic and environmental conditions. The need for the use of fire extinguishing systems and fire alarms is determined in accordance with Appendix A, standards, codes of practice and other documents approved in the prescribed manner.

1.3. This set of rules does not apply to the design of automatic fire extinguishing systems and fire alarms:

Buildings and structures designed according to special standards;

Technological installations located outside buildings;

Warehouse buildings with mobile shelving;

Warehouse buildings for storage of products in aerosol packaging;

Warehouse buildings with a cargo storage height of more than 5.5 m.

1.4. This set of rules does not apply to the design of fire extinguishing systems for extinguishing class D fires (in accordance with GOST 27331), as well as chemically active substances and materials, including:

Reacting with an extinguishing agent with an explosion (organoaluminum compounds, alkali metals);

Decomposable by interaction with a fire extinguishing agent with the release of combustible gases (organolithium compounds, lead azide, aluminum, zinc, magnesium hydrides);

Interacting with a fire extinguishing agent with a strong exothermic effect (sulfuric acid, titanium chloride, termite);

Self-igniting substances (sodium hydrosulfite, etc.).

1.5. This set of rules can be used in the development of special specifications for the design of automatic fire extinguishing and alarm systems.

- Normative references

In this set of rules, normative references to the following standards are used: GOST R 50588-93. Foaming agents for extinguishing fires. General technical requirements and test methods

GOST R 50680-94. Automatic fire extinguishing installations. General technical requirements. Test methods

GOST R 50800-95. Automatic foam fire extinguishing installations. General technical requirements. Test methods

GOST R 50969-96. Automatic gas fire extinguishing installations. General technical requirements. Test methods

GOST R 51043-2002. Automatic water and foam fire extinguishing installations. Sprinklers. General technical requirements. Test methods

GOST R 51046-97. Fire fighting equipment. Fire extinguishing aerosol generators. Types and main parameters

GOST R 51049-2008. Fire fighting equipment. Pressure head fire hoses. General technical requirements. Test methods

GOST R 51052-2002. Automatic water and foam fire extinguishing installations. Control nodes. General technical requirements. Test methods

GOST R 51057-2001. Fire fighting equipment. Portable fire extinguishers. General technical requirements. Test methods

GOST 51091-97. Automatic powder fire extinguishing installations. Types and main parameters

GOST R 51115-97. Fire fighting equipment. Fire monitors combined. General technical requirements. Test methods

GOST R 51737-2001. Automatic water and foam fire extinguishing installations. Disconnectable pipe couplings. General technical requirements. Test methods

GOST R 51844-2009. Fire fighting equipment. Cabinets are fire. General technical requirements. Test methods

GOST R 53278-2009. Fire fighting equipment. Shutoff fire valves. General technical requirements. Test methods

GOST R 53279-2009. Connecting heads for fire equipment. Types, main parameters and sizes

GOST R 53280.3. Automatic fire extinguishing installations. Extinguishing agents. Part

- Gas extinguishing agents. Test methods

GOST R 53280.4-2009. Automatic fire extinguishing installations. Extinguishing agents. Part 4. General purpose fire extinguishing powders. General technical requirements. Test methods

GOST R 53281-2009. Automatic gas fire extinguishing installations. Modules and batteries. General technical requirements. Test methods

GOST R 53284-2009. Fire fighting equipment. Fire extinguishing aerosol generators. General technical requirements. Test methods

GOST R 53315-2009. Cable products. Fire safety requirements. Test methods

GOST R 53325-2009. Fire fighting equipment. Technical means of fire automatics. General technical requirements. Test methods

GOST R 53331-2009. Fire fighting equipment. Trunks fire manual. General technical requirements. Test methods

GOST R 53329-2009. Robotic water and foam fire extinguishing installations. General technical requirements. Test methods

GOST 2.601-95. ESKD. Operational documents

GOST 9.032-74. ESZKS. Varnish-and-paint coatings. Groups, specifications and designations

GOST 12.0.001-82. SSBT. Key Points

GOST 12.0.004-90. SSBT. Organization of safety training. General provisions GOST 12.1.004-91. Fire safety. General requirements

GOST 12.1.005-88. SSBT. General hygiene requirements for working air

GOST 12.1.019-79. SSBT. Electrical safety. General requirements and nomenclature of types of protection

GOST 12.1.030-81. SSBT. Electrical safety. Protective grounding, grounding GOST 12.1.033-81. SSBT. Fire safety. Terms and definitions GOST 12.1.044-89. SSBT. Fire and explosion hazard of substances and materials. Nomenclature of indicators and methods for their determination

GOST 12.2.003-91. SSBT. Industrial equipment. General safety requirements.

GOST 12.2.007.0-75. SSBT. Electrotechnical products. General safety requirements GOST 12.2.047-86. SSBT. Fire fighting equipment. Terms and Definitions

GOST 12.2.072-98. Industrial robots. Robotic technological complexes. Safety Requirements and Test Methods

GOST 12.3.046-91. SSBT. Automatic fire extinguishing installations. General technical requirements

GOST 12.4.009-83. SSBT. Fire fighting equipment to protect objects. Main types, accommodation and service

GOST R 12.4.026-2001. SSBT. Colors are signal, safety signs and signal marking. Purpose and rules of use. General specifications and specifications. Test methods

GOST 3262-75. Steel and gas water pipes. Specifications GOST 8732-78. Seamless hot-deformed steel pipes. Range of GOST 8734-75. Cold-deformed seamless steel pipes. Range of GOST 10704-91. Electric-welded steel pipes. Range of GOST 14202-69. Pipelines of industrial enterprises. Identification coloring, warning signs and marking plates

GOST 14254-96. Degrees of protection provided by shells

GOST 15150-69. Machines, devices and other technical products. Versions for different climatic regions. Categories, operating conditions, storage and transportation regarding the impact of climatic environmental factors

GOST 21130-75. Electrotechnical products. Grounding clamps and grounding signs. Construction and dimensions

GOST 23511-79. Industrial radio interference from electrical devices used in residential buildings or connected to their electrical networks. Standards and measurement methods GOST 27331-87. Fire fighting equipment. Fire classification

GOST 28130-89. Fire fighting equipment. Fire extinguishers, fire extinguishing and fire alarm systems. Graphic Conventions

GOST 28338-89 *. Pipe connections and fittings. Conditional passages (nominal sizes). Ranks

Note - When using this set of rules, it is advisable to check the validity of reference standards, sets of rules and classifiers in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annually published information index "National Standards", which is published according to as of January 1 of the current year, and according to the corresponding monthly published information indexes published in the current year. If the reference standard is replaced (changed), then when using this set of rules, one should be guided by the replacement (changed) standard. If the reference standard is canceled without replacement, the provision in which the reference to it is given applies to the extent not affecting this reference.

- Terms and Definitions

In this rulebook, the following terms with the corresponding definitions apply:

3.1. Automatic start of the fire extinguishing installation: start-up of the installation from its technical means without human intervention.

3.2. Automatic fire extinguishing installation (AUP): a fire extinguishing installation that automatically operates when the controlled threshold factor (factors) exceeds the established threshold values \u200b\u200bin the protected area.

3.3. Automatic water feeder: a water feeder that automatically provides the pressure in the pipelines necessary for the operation of control units.

3.4. Automatic fire detector: A fire detector that responds to factors associated with a fire.

3.5. Autonomous fire extinguishing installation: a fire extinguishing installation that automatically performs fire detection and extinguishing functions, regardless of external power sources and control systems.

3.6. Self-contained fire detector: a fire detector that responds to a certain level of concentration of aerosol products of combustion (pyrolysis) of substances and materials and possibly other fire factors, in the casing of which an autonomous power source and all the components necessary for fire detection and direct warning of it are structurally combined .

3.7. Aggregate fire extinguishing installation: a fire extinguishing installation in which the technical means for detecting fire, storing, releasing and transporting a fire extinguishing agent are structurally independent units mounted directly on the protected object.

3.8. Addressable fire detector: a fire detector that sends its address code along with a fire notification to the addressable control panel.

3.9. Accelerator: a device that, when the sprinkler sprinkler is activated, opens the sprinkler air signal valve with a slight change in air pressure in the supply pipe.

3.10. Gas fire extinguishing battery: a group of gas fire extinguishing modules combined by a common collector and a manual start device.

3.11. Distribution piping branch: a portion of a distribution piping row located on one side of a supply piping.

3.12. Water-filled installation: a installation in which the supply, supply and distribution pipelines are filled with water in standby mode.

Note - The unit is designed to operate in positive temperatures.

3.13. Water feeder: a device that ensures the operation of AUP with the estimated flow rate and pressure of water and (or) an aqueous solution specified in the technical documentation for a specified time.

3.14. Aerial installation: installation in which in standby mode the supply pipe is filled with water, and the supply and distribution pipelines are filled with air.

3.15. Auxiliary water supply: a water supply that automatically maintains the pressure in the pipelines necessary for the control units to operate, as well as the estimated flow rate and pressure of the water and (or) aqueous solution until the main water supply reaches operating mode.

3.16. Gas fire detector: a fire detector that responds to gases released by smoldering or burning materials.

3.17. Fire-extinguishing aerosol generator (GOA): a device for receiving a fire-extinguishing aerosol with specified parameters and supplying it to a protected room.

3.18. Hydraulic booster: a device that reduces the response time of a deluge signal valve with a hydraulic actuator.

3.19. AUP standby mode: AUP is ready for operation.

3.20. Dictating sprinkler (spray): sprinkler (spray), the highest located and (or) remote from the control unit.

3.21. Remote start-up (start-up) of the installation: start-up (start-up) of the installation manually from start-up elements installed in or near the protected premises, in the control room or at the fire station, at the protected facility or equipment.

3.22. Remote control: a control panel located in a control room, isolated or fenced room.

3.23. Differential thermal fire detector: a fire detector that generates a fire alert when the ambient temperature rises above the set threshold value.

3.24. Dispenser: a device designed to dispense a foaming agent (additives) to water in fire extinguishing installations.

3.25. Fire extinguishing system: a fire extinguishing system equipped with deluge sprinklers or foam generators.

3.26. Drencher sprinkler (spray): sprinkler (spray) with an open outlet.

3.27. Smoke ionization (radioisotope) fire detector: a fire detector, the principle of which is based on recording changes in the ionization current that result from exposure to combustion products.

3.28. Smoke optical fire detector: A fire detector that responds to combustion products that can affect the absorbing or scattering ability of radiation in the infrared, ultraviolet, or visible spectral ranges.

3.29. Smoke fire detector: a fire detector that responds to particles of solid or liquid products of combustion and (or) pyrolysis in the atmosphere.

3.30. Extinguishing agent stock: required amount of the extinguishing agent stored at the facility in order to restore the estimated amount or reserve of the extinguishing agent.

3.31. Lock-starting device: a locking device mounted on a vessel (cylinder) and ensuring the release of a fire extinguishing substance from it.

3.32. Minimum irrigation area: normative (for sprinkler AUP) or estimated (for deluge AUP) area within which the normative irrigation intensity and, accordingly, the normative or estimated consumption of extinguishing agent are provided.

3.33. Control zone of fire alarms (fire detectors): a set of areas, volumes of premises of the facility, in which fire factors will be detected by fire detectors.

3.34. Inertia of a fire extinguishing installation: the time from the moment the controlled factor of the fire reaches the threshold of the sensing element of the fire detector, sprinkler sprinkler or inducement device until the fire extinguishing agent begins to flow into the protected area.

Note - For fire extinguishing installations, in which there is a time delay for the release of the extinguishing agent in order to safely evacuate people from the protected premises and (or) to control the process equipment, this time is included in the inertia of the AUP.

3.35. Extinguishing agent supply rate: amount of extinguishing agent supplied per unit area (volume) per unit time.

3.36. Delay chamber: a device installed on the line of the pressure signaling device and designed to minimize the likelihood of false alarms caused by the opening of the sprinkler signal valve due to sharp fluctuations in the pressure of the water supply source.

3.37. Combined Fire Detector: A fire detector that responds to two or more fire factors.

3.38. Local control panel: a control panel located in the immediate vicinity of the controlled technical means of the AUP.

3.39. Linear fire detector (smoke, heat): a fire detector that responds to fire factors in an extended, linear zone.

3.40. Main pipeline: a pipeline connecting the switchgears of gas fire extinguishing installations with distribution pipelines.

3.41. Maximum differential thermal fire detector: A fire detector that combines the functions of a maximum and differential thermal fire detector.

3.42. Maximum thermal fire detector: a fire detector that generates a fire alert when the ambient temperature exceeds a set threshold value - the detector's operating temperature.

3.43. Local inclusion (start) of the installation: inclusion (start) of the installation from the starting elements installed in the premises of the pumping station or fire extinguishing station, as well as from the starting elements installed on the fire extinguishing modules.

3.44. Minimum irrigation area: the minimum area upon which the fire extinguishing agent acts when the AUP is triggered with an irrigation intensity of at least standard.

3.45.

3.46. Modular pumping unit: pumping unit, the technical means of which are mounted on a single frame.

3.47. Modular fire extinguishing installation: a fire extinguishing installation consisting of one or several modules combined by a single fire detection and actuation system capable of independently performing the fire extinguishing function and located in or near the protected premises.

3.48. Fire extinguishing module: a device in the housing of which the functions of storing and supplying a fire extinguishing agent are combined when a starting pulse is applied to the module drive.

3.49. Pulse fire extinguishing module: fire extinguishing module with a duration of supply of extinguishing agent up to 1 s.

3.50. Nozzles: a device for the release and distribution of a gas extinguishing agent or extinguishing powder.

3.51. Nominal (conditional) pressure: the highest excess working pressure at a temperature of the working medium of 20 ° C, at which a specified service life of pipe and valve connections is provided, having certain dimensions, justified by the strength analysis for the selected materials and their strength characteristics at a temperature of 20 ° C.

3.52. Nominal (conditional) passage: a parameter used for pipeline systems as a characteristic of connecting parts, for example, pipe connections, fittings and fittings.

3.53. Regulatory extinguishing agent supply rate: The extinguishing agent supply rate specified in regulatory documents.

3.54. Regulatory extinguishing concentration: extinguishing concentration established in applicable regulatory documents.

3.55. Fire extinguishing aerosol: products of combustion of an aerosol-forming composition that extinguish a fire extinguishing effect.

3.56. Extinguishing agent: a substance with physico-chemical properties that allow the creation of conditions for the cessation of combustion.

3.57. Extinguishing concentration: the concentration of the extinguishing agent in the volume, creating an environment that does not support combustion.

3.58. Sprinkler: a device designed to extinguish, localize or block a fire by spraying water and (or) aqueous solutions.

3.59. Conditioner sprinkler: sprinkler sprinkler, which provides a signal to the control system of the automatic control unit and (or) to the control room about the activation of the thermal lock of this sprinkler.

3.60. Controlled sprinkler: sprinkler with an outlet shut-off device that opens when a control pulse is applied (electric, hydraulic, pneumatic, pyrotechnic or combined).

3.61. Main water supply: water supply, which provides the operation of a fire extinguishing installation with an estimated flow rate and pressure of water and (or) an aqueous solution for a standardized time.

3.62. Room leakage parameter: a value that numerically characterizes the leakage of the protected room and is defined as the ratio of the total area of \u200b\u200bconstantly open openings to the volume of the protected room.

3.63. Supply pipe: a pipe connecting the control unit to distribution pipelines.

3.64. Incentive system: a pipeline filled with water, an aqueous solution, compressed air, or a cable with thermal locks, designed to automatically and remotely turn on water and foam deluge fire extinguishing installations, as well as gas or powder fire extinguishing installations.

3.65. Supply pipe: a pipe connecting the source of extinguishing agent with control units.

3.66. Fire shut-off device: a device designed to supply, control and block the flow of extinguishing agent.

3.67. Fire detector (PI): a device designed to detect fire factors and generate a signal about a fire or the current value of its factors.

3.68. Fire flame detector: a device that responds to electromagnetic radiation from a flame or smoldering fire.

3.69. Fire station: a special facility facility with round-the-clock staff on duty, equipped with devices for monitoring and controlling fire automatics.

3.70. Fire alarm: a device for generating a signal about the operation of fire extinguishing installations and (or) locking devices.

3.71. A room with a mass stay of people: halls and foyers of theaters, cinemas, meeting rooms, meetings, lecture halls, restaurants, lobbies, cash rooms, industrial premises and other premises with an area of \u200b\u200b50 square meters. m or more with permanent or temporary stay of people (except emergency situations) of more than 1 people. per 1 square. m

3.72. Fire control device: a device designed to generate control signals for automatic fire extinguishing means, smoke protection, warning devices, other fire protection devices, as well as monitoring their status and communication lines with them.

3.73. Reception and control fire device (PPKP): a device designed to receive signals from fire detectors, provide power to active (current-consuming) fire detectors, issue information to light and sound annunciators of duty personnel and central monitoring panels, as well as generate a start pulse for starting a fire device management.

3.74. Fire control and control device: a device that combines the functions of a fire control and fire control device.

3.75. AUP operating mode: AUP performs its functional purpose after operation.

3.76. Sprinkler: a sprinkler designed to spray water or aqueous solutions (average droplet diameter in the spray stream is more than 150 microns).

Note: It is allowed to use the term “sprinkler” instead of the term “sprinkler”.

3.77. Switchgear: a shut-off device mounted on a pipeline and allowing the passage of a gas extinguishing agent into a specific main pipeline.

3.78. Distribution pipeline: a pipeline on which sprinklers, sprayers or nozzles are mounted.

3.79. Sprayer: a sprinkler designed to spray water or aqueous solutions (average droplet diameter in a spray stream of 150 microns or less).

3.80. Spray extinguishing agent flow: a liquid extinguishing agent flow with an arithmetic mean droplet diameter of more than 150 microns.

3.81. Fine spray extinguishing agent flow: drip extinguishing agent flow with an arithmetic mean droplet diameter of 150 microns or less.

3.82. Estimated amount of extinguishing agent: amount of extinguishing agent, determined in accordance with the requirements of regulatory documents and ready for immediate use in case of fire.

3.83. Extinguishing agent reserve: the required amount of extinguishing agent, ready for immediate use in cases of repeated ignition or failure to perform the fire extinguishing task.

3.84. Robotic fire extinguishing installation (RUE): a stationary automatic tool mounted on a fixed base, consisting of a fire barrel having several degrees of mobility and equipped with a drive system, as well as a software control device, designed to extinguish and localize a fire or cool technological equipment and construction constructions.

3.85. Robotic fire complex (RPK): a set of several robotic fire extinguishing installations combined by a common fire control and detection system.

3.86. Manual fire detector: a device designed to manually turn on a fire alarm in fire alarm and fire extinguishing systems.

3.87. Distribution piping row: a combination of two distribution piping branches located in one line on both sides of the supply piping.

3.88. Fire extinguishing installation section: an integral part of a fire extinguishing installation, which is a combination of supply and distribution pipelines, a control unit and technical equipment located above it, designed to supply a fire extinguishing substance to the protected object.

3.89. Pressure signaling device (DM): a fire alarm device designed to receive a hydraulic command pulse issued by a control unit and convert it into a logical command pulse.

3.90. Liquid flow signaling device (LNG): a fire alarm device designed to convert a certain amount of liquid flow in a pipeline into a logical command pulse.

3.91. Signal valve: normally closed shut-off device designed to issue a command pulse and start the extinguishing agent when the sprinkler or fire detector is triggered.

3.92. Fire alarm system: a set of fire alarm systems mounted at one facility and monitored from a common fire station.

3.93. Connecting lines: wired and non-wired communication lines providing a connection between fire automatics.

3.94. Sprinkler AUP with forced start: sprinkler AUP equipped with sprinkler sprinklers with controlled drive.

3.95. Light signaling: a technical tool (element) having a source of light radiation, perceived by the eye at any time of the day.

3.96. Water-filled sprinkler fire extinguishing installation: fire extinguishing sprinkler installation, all pipelines of which are filled with water (aqueous solution).

3.97. Sprinkler aerial fire extinguishing installation: a sprinkler fire extinguishing installation, the supply pipe of which is filled with water (water solution), and the pipelines located above the control unit are filled with air under pressure.

3.98. Fire sprinkler installation: an automatic fire extinguishing installation equipped with sprinkler sprinklers.

3.99. Sprinkler-deluge AUP (AUP-SD): sprinkler AUP, in which a deluge control unit and technical means of its activation are used, and the extinguishing agent is supplied to the protected zone only when the sprinkler sprinkler and technical means of activation of the control unit are triggered according to the “I” logic .

(Clause 3.99 as amended by Amendment No. 1, approved by Order of the Ministry of Emergencies of the Russian Federation dated 01.06.2011 N 274)

3.100. Sprinkler sprinkler (spray): sprinkler (spray) equipped with a thermal lock.

3.101. Fire extinguishing station: vessels and equipment of fire extinguishing installations located in a special room.

3.102. The degree of leakage of the room: expressed as a percentage of the total area of \u200b\u200bconstantly open openings to the total surface area of \u200b\u200bthe room.

3.103. Thermal lock: a thermosensitive shut-off element that opens at a certain temperature.

3.104. Thermal fire detector: a fire detector that responds to a specific temperature and / or rate of rise.

3.105. Fine spray extinguishing agent flow: a liquid extinguishing agent flow with an arithmetic mean droplet diameter of 150 microns or less.

3.106. Air sampling point (air sampling hole): a hole in a special air pipe through which air is drawn in from the protected space.

3.107. Point fire detector (smoke, heat): a fire detector that responds to fire factors in a compact area.

3.108. Specific consumption of water curtain: flow per one meter of curtain width per unit time.

3.109. Control unit: a set of technical means of water and foam AUP (pipelines, pipe fittings, shutoff and signaling devices, accelerators or moderators, devices that reduce the likelihood of false alarms, measuring instruments and other devices), which are located between the supply and supply pipelines of sprinkler and deluge water and foam fire extinguishing installations, and designed to monitor the status and verify the operability of these installations during operation, as well as for starting a fire extinguishing agent, issuing a signal for generating a command pulse for controlling fire automatics elements (fire pumps, warning systems, ventilation and technological equipment, etc.).