Roof to wall junction - installation

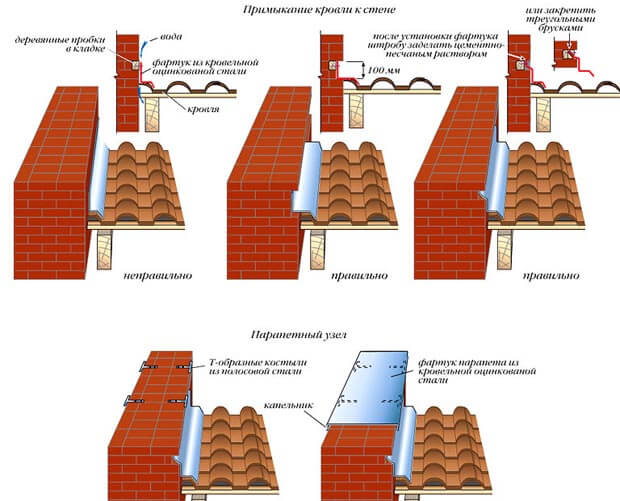

As you know, those areas of the roof where the coating is in direct contact with the wall are most susceptible to the negative effects of moisture. Therefore, it is in the place where the junction of the roof to the wall is located that the sealing of the joint and its protection must be performed at the highest possible level.

It is customary to distinguish two main types of junctions - top and side, and the device of each of them requires the use of butt strips PS-1 and PS-2.

The need for roof connections

It is very important that all elements of the structure, one way or another adjacent to the roof (ventilation and chimney pipes, canopies, walls, sheds, etc.), are arranged according to a specially planned plan. As you know, these places are most susceptible to the active accumulation of any moisture.

Inconvenience is also often caused by debris, branches and foliage of trees that accumulate in those places where the wind blows most strongly. In winter, the junction of the roof to the wall under the influence of snow experiences the strongest loads.

After the installation of the roof truss system is completed, it is only necessary to equip the roof with the necessary coating.

Metal tile flooring must be laid with a small gap near the walls. This is done in order to provide the entire structure with normal ventilation, while doing the right thing. After that, in the wall canvas, by means of chasing, you need to create a groove having a depth of about 2.5 centimeters. At the same time, the butt plate is equipped with a special seal, and then it is tightly fixed in the groove and fastened with dowels. Then the place of gating is treated with a special silicone-based sealant. The junction bar is fixed on the upper points of the tiled waves using self-tapping screws or screws.

In the event that the roofing is covered with rolled material, for example, a coating of bitumen or bitumen with polymers, then the adjoining of the roof to the wall should be processed according to the following principle:

- Clamping rails are applied to the sections of the joints of the coating with the wall.

- The superimposed rails must be firmly fixed with self-tapping screws.

- Joint areas are treated with a silicone-based sealant.

- As an option - the imposition of elastic mastic along with reinforcing geotextile, and on top - the second layer of mastic. This method is called flashing. It has gained quite wide popularity due to the good end result of the work - the seams are elastic, durable and perfectly sealed. This method is relatively inexpensive, and besides, it can be carried out with one's own hands, without attracting extra labor and without spending material resources on paying specialists.

Apply the mastic to the joints with a brush or roller. This material hardens quickly, but the necessary elasticity, however, is maintained. Adhesion of mastic with almost any material passes without any problems.

Thanks to the polyurethane that is part of the material, the coating acquires additional plasticity and endures absolutely any kind of impact. The service life of such flooring can reach more than 20 years, and the quality does not suffer even at such a greater temperature range as from -40 to +75 degrees.

Joints are prepared for the flashing method in different ways depending on the materials used for the construction of roofing joints, as well as on their configuration. This is done as follows:

In total, for 1 m² of joints, on average, it is required to use about 1 kilogram of mastic. The volume of primer consumption is approximately equal to 0.3 kilograms per 1 m². It is necessary to calculate the consumption of geotextiles even before purchasing it.

Installation of junction strips, detailed video:

Roof connection to other elements of the structure

If it is necessary to seal the joints of the roofing with other surfaces of the entire structure, then the technology should be somewhat different. For example, if the roof is adjacent to the parapet, then this element must be insulated.

Wall insulation with such sealing is carried out using mineral wool. In the area where the roof is connected to the parapet, one more layer should be welded.

Thermal insulation sheets must be covered with particle-cement boards or slate, usually flat. A dense slab of mineral wool serves as the basis for creating a sloping edge, which is glued directly into the corner over hot bitumen. The very first of the layers of the roof covering should be bent onto a horizontal surface at a distance equal to 15 centimeters, and the second layer must overlap the previous one at a distance of 5 centimeters.

After that, you should proceed to the arrangement of a steel apron, the main function of which is to drain rainwater. After that, the junction of the roof to the wall will have a reliable and long-term sealing.

Due to the wavy shape of this material, it is able to repeat the shape of the coating itself, that is, the tiles, and the subsequent pouring of bitumen will finally give the joints complete tightness. Tapes of this kind can also be used on shingles. Another advantage is their rich color range, so choosing the right shade for the color of the roofing will not be difficult.

If you have any questions about how the roof should be connected to the wall and other surfaces, detailed information with photos and videos of all work can always be found on the Internet.