How to cut a hole in drywall

Today, during repair work, drywall has found very widespread use. In this regard, for the installation of various elements in walls and ceilings made of gypsum plasterboard, it became necessary to use special drills - drywall crowns. What is it, how to choose and apply them?

What is this article about

What is a crown

How to cut a smooth round hole in drywall of the required diameter? To do this, use a cutter in the form of a cylinder with a cutting toothed edge on one side and a "tail" for attaching the cutter to the drill on the other. The drill is located in the center of this cylinder. This whole design is called a plasterboard crown, or a core drill. How it works: the drill enters the drywall first and sets the center of the future hole, while the nozzle is fixed in the desired position, the edge of the cutter enters the surface and makes a cut of the circle.

Types of crowns

Core drills can be divided into two types: solid and collapsible.

- Solid crowns are a drill with one metal toothed cylinder on it;

- The collapsible crown device contains a universal disc into which cylinders of different diameters can be inserted. The cylinders themselves are open-ended and come with a disc. As with solid crowns, the collapsible edge is serrated.

The cylinder diameter can be varied from 33 to 150 mm.

For making holes in drywall, crowns for both wood and metal are suitable. There are universal - bimetallic crowns that can be used to drill metal, wood, gypsum board, of course they are more expensive, but if you use them only for drywall, then we can say that they are eternal. When buying a bimetallic bit, you should pay attention to the fact that they are usually sold without a holder and a centering drill. In the assembly, this is called an adapter, which will have to be purchased separately.

Selection of cutters

Arriving at the store, it is not difficult to get confused by the abundance of crowns on offer. How not to be mistaken with the choice so that it does not break when making the first hole?

- Taking the crown in your hands, take a good look at it. If these are products of poor quality, you can visually immediately see, for example, elements, inaccurate processing, defective coating. It is worth paying attention to the tail of the crown, if it is too light, then it is made of low-quality metal and can quickly break;

- The centering drill and shank must be firmly secured, no gaps allowed. Also, if this is a collapsible crown, you need to check, each cylinder included in the kit, how easily and exactly each of them fits into the groove of the disc. Make sure that none of the cylinders is loose in the groove, because the quality of the cut will depend on this;

- The element of the crown, which carries the maximum load during drilling, is cylinders (glasses) with a serrated edge. The service life of the entire device depends on the quality of the material of this element. The saws should not be too thin or bend easily, the material should be resilient, otherwise you may not get the hole. Hardened tooth saws are better quality and more durable. Do not forget - the cutting teeth must provide a clear and even cut of the material;

- Core drills have different sizes (barrel diameter, drilling depth), if you take a set, make sure it contains the one you need.

Crown for mounting boxes

The most common need to drill round holes in drywall is to install power outlets. The invisible part of the socket, the plastic round mounting box that is mounted in the wall, is called the socket. There are socket boxes for concrete, wood and drywall.

A drywall box is a plastic cup with adjustable plastic or metal plates. Thanks to these "paws", the socket is fixed to the back of the drywall sheet. The depth of the back box can be 40, 50, 60 or 73 mm. As for the diameter, for a standard socket it is, as a rule, 68-70 mm.

If you only need to drill holes for socket mounting, you only need one crown. In this case, you should not purchase a set of collapsible crowns. It is enough to buy one special core drill, with a diameter of 68 or 70 mm (depending on the size of your socket boxes).

To date, the diameter of a core drill for plasterboard of 68 mm is the most demanded standard size.

Spotlights

Spotlights are widely used today, the so-called spots, which are a point source of light. In most cases, spots are installed in plasterboard ceilings or boxes. For installation it is necessary to cut a hole with a diameter corresponding to the diameter of the ceiling lamp. Usually, the required diameter for cutting is written on the packaging from under the lamp or in the instructions for it, but it so happens that there are no instructions, then you should measure the diameter yourself. This can also be done simply to check the specified information, so as not to accidentally make a hole of the wrong diameter, because then nothing can be fixed.

The most common spot hole diameters are 60 and 75 mm. To get a hole of the required diameter, you should use a special drill - a drywall crown. The main thing is when you choose the size of the crown for drilling a hole for a spotlight, so that the drilled diameter is less than the diameter of the spot, that is, the lamp must completely cover the gift during installation.

Organization of the drilling process

Everyone uses different crowns depending on their needs, but whichever drill you use, you can draw up general instructions for their use.

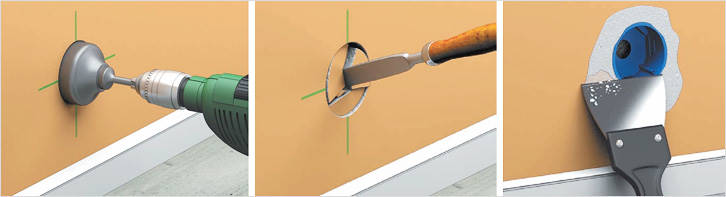

The whole process can be divided into several stages:

- determination of the location of the holes on the drywall;

- marking of surface material;

- fastening a core drill to a power tool;

- directly drilling.

At the first stage, you should decide where, how many, what diameter the holes will be. It is better if you already have the elements to be mounted (lamps, socket boxes, etc.), then it is easier to determine all the required hole diameters and thereby avoid unnecessary mistakes. Ideal if there is a visual layout diagram.

Next, the surface is marked. Measurements are made and the points of the center of the holes are applied to the surface of the drywall, where the centering drill subsequently enters. Be careful that the hole does not hit the location of the metal profile, in this case you will be forced to cut the metal as well. If, for example, you cannot see where the profile is located by the caps of the screws, and you have not been fixing drywall, then you should find out where the metal passes before drilling, perhaps you need to ask the wrap-up team in advance to put some marks. Another way to find out the location of a profile is to use a search magnet. If you plan to place several elements side by side, then when marking up you need to follow the level.

At the third stage, a crown of the required diameter is taken and installed on the power tool. It can be a drill or screwdriver. To use the punch, you need to purchase an adapter cartridge and do not forget to turn off the impact mode.

Further, after you have made the calculations and markings, you can go directly to drilling. The centering drill of the crown is placed on the center of the future hole and the power tool is switched on slowly. In this process, large tool powers are not needed. The main thing is to keep the tool straight so as not to get a beveled cut. The drilling process can be carried out both already on the fixed drywall, and not yet on the sheets being mounted, without applying strong pressure on the gypsum board.

Drywall is a fairly soft material, and having a cutter of the right size and quality, it is not difficult to make an even hole, but still, if in doubt, trust the professionals.