Installation of a gas boiler in a private house requirements

For heating a private house, the best option, of course, is a gas boiler. This heating unit has a high efficiency and allows you to quite smoothly and flexibly adjust the intensity of heating of residential premises, sometimes even without the use of additional thermostatic devices. Today, gas is considered the most profitable fuel in terms of efficiency, so the cost of such a boiler will quickly pay for its purchase and installation costs.

If you plan to install a gas boiler in a private house, the requirements for the room and the heater itself must be clarified in advance. Having received general information, you can be sure that you have to collect a lot of different documents and go around several instances. Therefore, it is worth preparing not only theoretically and technically, but even psychologically for these rather unpleasant, but, alas, necessary events.

Basic regulatory documentation for boiler installation

All these data can be found in SNiP (Building Norms and Rules) 31-02-2001, “Gas supply of a country house. Requirements and rules for the installation of gas equipment.

In addition to this document, you need to view additional ones containing information on the arrangement of boiler rooms and the rules for installing a boiler. They can also be found in among the "Building Norms and Rules":

- SNiP 41-01-2003 "Heating, ventilation and air conditioning".

- SNiP 21-01-97 "Fire safety of buildings and structures".

- SNiP 2.04.01-85 "Internal water supply and sewerage of buildings".

To equip a boiler room in a private house, you should study SNiP 2.04.08-87.

How is a boiler room equipped in a private house?

In your own house, a separate room is usually allocated for heating equipment. What requirements should the boiler room meet? - detailed information about this is set out in a separate publication of our portal.

Coordination of the installation of a gas boiler

In order to install a gas boiler in a private house or apartment, it will not be enough to study the SNiP documents. First you need to obtain technical conditions that will become the basis for organizing further work on connecting equipment to gas pipelines.

To do this, the landlord submits an application to the local gas supply service, which indicates the estimated gas consumption required for use in a particular building for heating and for other needs. This parameter is calculated approximately on the basis of SNiP 31-02, clause 9.1.3, which shows the average daily gas volume for a single-family house:

– gas stove (cooking) – 0.5 m³/day;

- hot water supply, that is, the use of a flowing gas water heater (column) - 0.5 m³ / day;

- heating using a domestic gas unit with a connected water circuit (for central Russia) - from 7 to 12 m³ / day.

In the local organization that controls the gas supply and installation of boiler equipment, the request is considered by specialists. For the applicant, a document is drawn up with technical conditions or with a reasoned refusal. The review process may take from one week to a month, depending on the efficiency of the work of this controlling service.

If the request is satisfied, then the technical conditions are issued, which must be fully implemented during the installation of gas equipment. This document will simultaneously be a permission to carry out the relevant work.

It is necessary to know for sure that the installation of gas equipment without obtaining technical conditions is illegal. In addition, uncoordinated independent installation of the boiler is very unsafe, especially in cases where such work will be carried out in a multi-storey building. Sad examples of this, alas, are plentiful.

Installation project development

When the technical conditions are received, you can proceed to the preparation of the installation project.

The project is developed taking into account all the requirements specified in the technical specifications. This also includes a scheme for laying gas communications: for a private house - along the site to the entrance to the residential building, indicating this point in the drawing, and for an apartment - from the entrance to the gas supply pipe to the point of connection to the autonomous system heating boiler.

The development of the project should be carried out only by specialists-designers who have a license to carry out work of this type. As a rule, an organization dealing with gas supply in a particular region (settlement) has a design department, where all such surveys, calculations and their graphic design are carried out.

Project approval

Further, the finished project is sent for approval to the department of the organization that controls the gas supply to the house where the gas boiler will be installed. The period of coordination of the submitted documents depends on the complexity of the project scheme, and can take from one week to three months.

The following documents with the characteristics of the boiler equipment must be attached to the project for the installation of the boiler and the supply of the gas pipeline submitted for approval:

- Technical passport of the gas boiler.

- Instructions for its operation.

- Certificates of compliance with technical and sanitary requirements.

- Expertise data on the compliance of this unit with all safety requirements.

These documents are issued to the buyer by the seller together with the boiler, and they are issued by the manufacturer of boiler equipment.

If the project has not been approved, then in addition to a reasoned refusal, the applicant is given a list of the actions that must be taken to obtain a positive conclusion.

If the project is approved, it is certified accordingly, which means that it is already possible to carry out practical work on the installation of gas heating equipment.

Basic requirements for the boiler room

A separate room must be provided for the installation of gas equipment with a capacity of 30 kW or more. It must comply with all existing standards and regulations. Quite often, they try to choose one of the rooms in the basement or basement for the boiler room, but you need to know that such a gas boiler installation is only allowed for single-family private residential buildings.

A boiler of any capacity can be installed in a private house, since it is usually placed in a room attached to the house, thus making it possible to heat not only living quarters, but also utility rooms.

General requirements

The main requirements for the boiler room are as follows:

- The area of the room for the installation of one boiler must be at least 4 m². At the same time, the total number of boilers in one room can never be more than two.

- The ceiling height of the room is not less than 2200÷2500 mm.

- The window, which is obligatory in the boiler room for natural light, must be sized for every 10 m³ of room volume 0.3 m² of window area, but in any case not less than 0.5 m².

- The width of the door opening must be at least 800 mm.

- The distance between the front door and the boiler cannot be less than 1000 mm, but it is better if this interval is 1300÷1500 mm.

- In order to be able to carry out maintenance and repair work, the necessary free space must be provided in front of the boiler, which must be at least 1300 mm.

- The boiler must be installed steadily and in a strictly horizontal position - this will minimize possible vibrations and noises.

- The floor in the boiler room must be made of non-combustible material and be perfectly flat.

- The walls must also be made of non-combustible materials, and the surfaces near the boiler walls can be additionally insulated with heat-resistant materials.

- Cold water must be supplied to the boiler room. In the floor of the room, it is necessary to equip a system for draining the coolant into the sewer.

- Electrical sockets must have a ground loop, as some elements of the boiler, such as an ignition or a pump, are connected to the power supply.

- It is necessary to provide access to the chimney - in particular - to the inspection window - to control the patency of the channel and the possibility of cleaning.

Ventilation and chimney systems

Ventilation and exhaust systems for gas combustion products in the boiler room must be installed in compliance with the rules for installing gas equipment, since a malfunction or inefficient operation of these systems can either lead to equipment inoperability, or, even worse, to an emergency and even explosive situation.

The following requirements are imposed on ventilation and chimney by regulatory documents:

- Ventilation and chimney ducts must be separated.

- For fresh air to enter the boiler room, supply ventilation must be provided. The entrance window is made at the bottom of the outer wall or front door. The size of the ventilation window should be not less than 1/30 of the total area of the room, but not less than 80 mm² per 1 kW of power of the installed gas unit - for air supply from the street, and not less than 300 mm² per 1 kW if air supply is from another room.

- Ventilation ducts must always be open, as air must circulate constantly.

- The boiler is recommended to be installed as close as possible to the chimney.

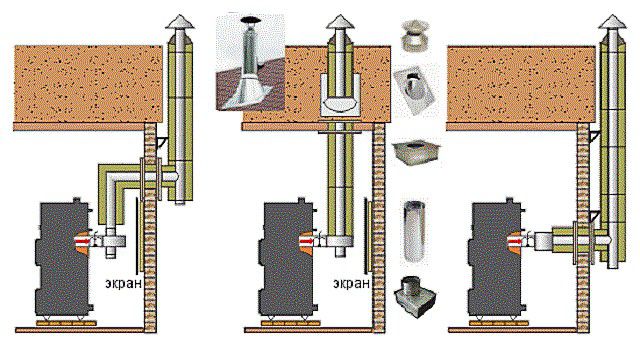

- A chimney arranged in a wall must have two inlets:

- the main one, for the installation of a chimney pipe;

- revision, located below the first not less than 250 mm - this channel is intended for technological cleaning.

- The exhaust outlet of the chimney must not have a section smaller than the outlet pipe of the boiler itself.

- The chimney should not have more than three bends or turns.

- The chimney is made of stainless or carbon steel sheet. The use of asbestos-concrete pipes or other pipes made of laminated materials is allowed only at a distance of at least 500 mm from the boiler chimney.

- In order for the operation of the boiler to be safe and the heating system itself to be efficient, favorable conditions must be created to maintain normal draft. Therefore, it is very important to calculate both the total height of the chimney and its location above the roof surface so that the head does not fall into the zone of the so-called wind backwater.

So, for the chimney of a gas boiler, there are certain standards:

- above a flat roof that does not have a ridge, the pipe must rise at least 500 mm above the roof or above the parapet, if there is one along the perimeter of the roof;

- if the pipe exits through the roof slope at a distance from the ridge of less than 1500 mm, then its head rises above it by at least 500 mm;

- provided that the pipe exits through the pitched roof at a horizontal distance of 1500 ÷ 3000 mm from the ridge, the head must be raised to a level not lower than the top of the ridge;

- if the chimney passes through a pitched roof at a distance of more than 3000 mm from the ridge, then its outlet should be located on a conditional line drawn at an angle of 10˚ to the horizon from the top of the ridge.

The best solution is to install a sandwich chimney

In our time, the problem of creating a reliable system for the removal of combustion products is solved much easier. Fast and reliable allows you to speed up the introduction of boiler equipment into operation. More about this in a special publication of our portal.

A few words about gas boilers

Nowadays, the consumer is presented with a wide range of gas heating equipment of domestic and foreign manufacturers. it remains only to make the right choice.

Gas boilers can be divided into several types according to various criteria:

- by design;

- according to the installation method;

- by rated power,

- by type of ignition;

- according to the technology of removal of combustion products.

- According to the basic design, boilers are divided into single- and double-circuit.

- The first ones are intended to provide a heating system, and if it is necessary to use them for hot water supply, an additional device will have to be installed - an indirect heating boiler.

- Double-circuit models are designed both for heating and for providing hot water. They can work on the flow principle of heating or be equipped with a built-in boiler that heats and maintains a certain supply of heated water for domestic needs .. Therefore, this unit can be called universal.

Single-circuit boilers are often abbreviated as AOGV - a gas-fired water heating unit.

Double-circuit devices designed for heating and providing hot water are designated AKGV - a combined gas water heating unit.

- According to the method of installation and installation, gas units can be wall-mounted and floor-standing.

- Floor boilers usually differ from wall-mounted boilers in higher power. As a rule, they try to place them in boiler rooms so that they do not clutter up the premises with their dimensions.

- Wall-mounted versions of gas appliances are becoming more and more popular, as they can be installed even in an apartment. The use of such equipment is also convenient because the removal of combustion products does not require the construction of a "classic" chimney - it can be carried out directly to the street through an external wall by means of a coaxial chimney, which simultaneously provides the supply of air necessary for burning gas.

All modern gas heating boilers are equipped with automatic protection systems of one level or another of complexity, but they necessarily provide for stopping the gas supply to the burners in case of leaks, interruptions in the gas line, overheating of the coolant, and lack or insufficiency of draft in the chimney.

An important selection criterion is always the power of the boiler, that is, its ability to generate a certain amount of thermal energy per unit of time (kWh).

The selection of the required model for this parameter is carried out on the basis of calculations in which the base initial value is the area of heated premises.

Often in everyday life, this parameter is calculated by the ratio in which 1 kW is allocated for every 10 m² of area, plus, of course, up to 15 ÷ 20% of the reserve so that the boiler does not work at the limit of its capabilities.

The calculation formula looks like this:

W \u003d S × Wsp / 10

W- boiler power,

S- area of heated premises,

Wud— specific power for heating 10 m².

Moreover, the specific power may vary depending on the region of residence, for example:

- Northern region - 1.5 ÷ 2.0 kW.

- The middle zone of Russia is 1.0 ÷ 1.2 kW.

- Southern region - 0.7 ÷ 0.9 kW.

Such an approach to determining the required thermal power has a right to exist. But still it does not differ in accuracy, since it does not take into account a number of features of the house itself. If the reader has a desire to make a more accurate calculation, we recommend that he use a special calculator that contains correction factors for the specifics of a particular heated room.

To work, you will need a plan of your residential properties and the availability of some additional available information about the parameters of the premises. The calculation is carried out for each heated room separately, and then it will not be difficult to sum the obtained values \u200b\u200bin order to obtain the recommended power of the gas boiler. By the way, the calculated indicators for each room separately will also help in the correct selection of the necessary heating radiators.

If any data (for example, the position relative to the cardinal points, "wind roses", etc.) is unknown, then this field can be left blank when entering. But in this case, the calculation will be carried out taking into account the most unfavorable conditions.