Foundation for a fireplace stove. Foundation dimensions: under the fireplace, under the house Do-it-yourself foundation for the fireplace

Fireplaces and stoves made of brick are very significant structures with an impressive height. They are usually assembled from a large number of fairly small components.

It should be remembered that the distance between the foundations of the wall and the fireplace should not exceed more than 5 cm.

Under the complex design, impressive size and heavy weight of such structures, the construction of the foundation is required according to special strict standards. The foundation for a fireplace in your home must withstand the load intended for it and comply with all necessary building codes.

This base is designed to support the entire fireplace or stove system so that structural distortions do not occur.

The entire heating mechanism must be placed in strict proportion to the vertical axis type. If the foundation for the fireplace is of poor quality, then it can cause cracks and other surface damage. Such shortcomings reduce the effectiveness of the entire heating system. They can quite often disable it, making it impossible to heat their own home.

Feature of the fireplace foundation

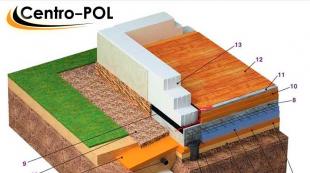

Scheme of the device of the fireplace.

The foundation for a fireplace can be made of waterproof brick, building stone and concrete. Between the bases of the dwelling and the furnace, it is necessary to make a gap of 52-57 mm and fill it with compacted sand. It is strictly forbidden to bandage these foundations, since they give a variety of sediment, causing the possibility of cracks. The width of the base for a fireplace or stove should be 12-17 cm larger than the structure itself.

Building a foundation for these heating systems with your own hands is practically no different from making the foundation for any other object. In this regard, the simultaneous construction of a house and the creation of a brick fireplace are considered optimal. This will save many owners from unnecessary material costs associated with opening ceilings and floors. The foundation on which the walls of the building are located carries a slightly different load than the foundation for a stove or fireplace. For this reason, it is undesirable to make the entire base one-piece, since they have unequal dimensions and shrinkage. A prerequisite is the presence of a sand-covered gap between the foundations of at least 4 cm.

The surface and the fireplace should be at least 6 cm larger than the size of the fireplace table, and its depth should not be less than 1.5 m. Due to the pressure of the base, sandy soils compact and subside, and it also quickly sags. The quality of clay soil layers directly depends on the level of humidity. Wet soil cannot bear the load placed on it. For this reason, it is not necessary to place the foundation for a stove or fireplace on wet clay.

Back to index

Do-it-yourself technology for building a fireplace foundation

In the process of creating a foundation for a stove or fireplace in the house, you will need the following materials:

- concrete mixture (water, sand, crushed stone, cement);

- sand;

- brick;

- cement mortar;

- rubble stone;

- gravel.

You should also prepare the following tools:

- concrete mixer;

- tape measure, cord and clothespins;

- formwork;

- hammer;

- Bulgarian;

- shovel;

- level;

- welding machine;

- screwdriver

Before building a foundation for a stove or fireplace with your own hands, you need to dig a foundation pit, the parameters of which can exceed the dimensions of the base by 12-17 cm. Its depth should be approximately 75-110 cm for a two-story house and 65 cm for a one-story house. In non-rocky soils, a straightening sand pad should be placed at the very bottom of the pit. In heaving soils, it is made gravel-sand - 60% gravel and 40% sand.

Scheme of the device foundation for the fireplace.

The height of this pillow must correspond to a similar parameter of the foundation of the building itself. It must be placed with continuous moistening and in layers. Before you organize the pillow, you must smooth and compact the bottom soil of the excavation. It is necessary to perform tamping manually or automatically. With the help of the level, it is necessary to control the horizontalness of the base.

All puddles that have formed at the bottom of the pit after the rains should be scooped out. If the soil has become fluid-plastic, it is cut to the value of the initial state. If the walls of the excavation made remain vertical and groundwater does not enter it, then the foundation for the furnace can be made of both rubble concrete and brick. Here it is necessary to calculate which method is more economical, taking into account such important factors as, for example, the dimensions of the structure, the cost of materials and their transportation.

If the foundation for the furnace is placed with an inclination, as well as subsidence and movement of the soil, additional forces may arise that contribute to the destruction of the foundation. This base must be raised to a level that will be 15-16 cm below the floor. Strictly in a horizontal position, you need to very carefully straighten the surface with a cement composition. The upper part of the base on which the fireplace is installed can only be processed after the above mixture has completely solidified.

The surface is laid out on a cement mortar with two rows of bricks. Between them are laid 2 layers of material for waterproofing. The best option is the end of the foundation strictly at the level of the finished floor. The base of the fireplace is installed on it, which means the part of the system located below the firebox.

Back to index

Concrete, concrete and pile foundation for a stove or fireplace

Scheme of the construction of a concrete foundation for a furnace.

To build a base for a fireplace or an oven made of rubble concrete, first of all, formwork should be made. Its internal planes are sheathed with glassine, roofing material, roofing felt or coated with bitumen so that cement milk from concrete does not go into the sand. After that, the formwork must be placed on the prepared base and put the first layer of large stones into it. The space between them is filled with rubble. This laid layer must be well impregnated with cement mortar.

Next, you need to make a mixture of cement and sand, which is very thoroughly mixed. To obtain the composition of the consistency of thick sour cream, water should be constantly added to the solution. It is necessary to fill in 1 row of the located buta at a time. Every other day it is optimal to form the second and third layer of the mixture. Experts recommend doing the job in one go without interruption.

The concrete foundation for a stove or fireplace is made from a solution of sand, Portland cement and gravel. This building mixture is poured into a pit with a reinforcing mesh. As a rule, concrete is poured in 2 steps. The reinforcement after the first portion should be covered with a concrete layer and compacted. Next, pour the rest of the foundation. The concrete sets completely in about 2 days. It should be protected from direct sunlight in the summer, for example, by covering it with a layer of roofing material. To increase the strength of the concrete foundation, it is recommended to water it frequently.

In summer, formwork can be removed after 6-8 days, and in a cold period of time - after 9-14 days. If the foundation plane after that will have flaws in the form of small pores and shells, then it is necessary to carry out its additional waterproofing. It is enough to carry out plastering with a composition of clean fine sand and cement, if there is no groundwater in the soil. Next, you need to fill the pit with non-porous soil.

With the deep foundation method for the furnace, 4 support piles can be used, which are connected from above with a special reinforced concrete screed. They can be made from asbestos-cement pipes, which are reinforced inside with iron rods and filled with concrete mortar. For a mass pressure of approximately 7 t, the total bearing area must be calculated. The main section and size of each pile with a soil bearing capacity of 1.5 kg / cm² should be equal to 1600 cm².

When building a foundation for a stove or fireplace with your own hands of any kind, be sure to level its upper platform. It must be checked for horizontality and smoothed. The maximum level should be 7-8 cm lower than the floor. To waterproof the chimney masonry for any foundation, 2 layers of roofing material with a bituminous coating are used.

Since ancient times, people love to be around the fire. Having learned how to build a dwelling, he brought a fire into it.

They warm themselves near the fire, rest, cook food on it. In the modern world, a fire replaces a fireplace.

Today, the device of fireplaces in country houses is especially popular. Since a standard fireplace has a mass of about one ton, a foundation must be made under it. What should be the dimensions of the foundation under the fireplace? We will talk about this in this article.

Fireplaces themselves are a composition of an internal functioning device and an external decorative frame. A functioning device consists of a chimney passing into a chimney and a firebox. A brick, marble fireplace is a picturesque element of any interior.

Where to place the fireplace?

Before you start laying a fireplace, you need to determine the place of its laying, and then complete the foundation. This is best done at the design or construction stage. In this case, you can build it into the wall. When designing a fireplace location, consider objective factors, namely: fire safety and work efficiency:

You should not place a fireplace in the corridor, near the stairs or the door, because drafts are highly undesirable for it. Its portal should be directed to the central part of the room in order to organize a place of rest;

- Since the air circulation is greatly increased when the fireplace is located opposite the windows, the fireplace should not be positioned so that the radiation surface is opposite the windows;

- Interior items: cabinets, carpets, tables should be at least 1 meter away from the fireplace;

- It is recommended to install fireplaces in rooms with an area of at least 11 m2. The room must have either an opening window or an opening. In this case, sufficient oxygen will be supplied, which is necessary for normal combustion.

What should be the foundation of the fireplace?

A medium-sized fireplace usually has a mass of 800 kg to 1 ton. The foundation under the fireplace must be strong enough so that cracks do not form on the fireplace.

The foundation must be made of moisture-resistant iron brick, concrete or rubble stone. It should be laid to a depth below the freezing depth of the soil. The foundation for the fireplace is carried out separately from the foundation of the house. They should not be tied up, because they can shrink differently and cracks form in the fireplace.

In order to prevent erosion and corrosion of the masonry in the fireplace, horizontal waterproofing should be provided in the foundation. Roofing material can be used as a waterproofing material.

The size of the fireplace foundation should be larger than the fireplace itself by 12 ... 15 cm in cross section. The pipe should be placed as close as possible to the center of the base, since it is she who bears the main load. This arrangement will avoid load asymmetry and uneven shrinkage of the foundation.

In the event that the base of the fireplace is located near the main foundation, it is necessary to make a sand backfill, the thickness of which is not less than 50 mm. It should be ensured that the pipe does not get into the rafters and ceiling beams.

The depth of the foundation of the fireplace depends on many factors. It is affected by:

- Type of soil (degree of its strength or heaving);

- freezing depth;

- Ground water level.

To start the foundation, you should dig a pit, the dimensions of which are 15 cm larger than the size of the foundation for the fireplace. The depth of the foundation must be at least 60 cm or according to the level adopted in the area for the construction of foundations. At the bottom of the pit we lay a layer of up to 15 cm of crushed stone and ram it.

Consider how to make a foundation of rubble concrete. We manufacture formwork of the required height and appropriate dimensions. The inner wall of the formwork must be waterproofed with glassine, felts or roofing material.

The formwork is placed on the base, then the bottom layer of large stones is laid. Then they are covered with crushed stone and spilled with cement mortar 1:3 (cement-sand ratio). To prepare the solution, mix cement and sand, and then dilute the mixture with water to the consistency of thick sour cream.

The top of the concrete is leveled, smoothed, checked for level and maintained for 7 days. After a week, you can continue laying the fireplace.

How to lay the foundation of a house?

The foundation for a house of size 6 9 is made in the same way as the foundation for a fireplace.

The construction of the strip foundation begins with the markup. Columns are buried along the perimeter at a distance of 1 meter from the edge of the future pit. Marks should be 20 cm above the floor level of the house. The intersection of the axes means the outer boundaries of the foundation.

Having marked a 6x9 rectangle, you should check its diagonals. They must be equal.

Before digging a trench throughout the building area, the vegetation layer is removed from the surface of the earth. If the soil in the area is subsiding, then it should be compacted to prevent deformation of the structure.

If you plan to make a strip foundation, then it can be made of rubble concrete (its device was described earlier) or from monolithic concrete.

From a wooden board up to 5 cm thick, formwork should be built. The formwork must be strictly vertical. It is necessary to mount vertical and horizontal fittings in it. Assemble into a frame with an installation step of 10 to 25 cm. The frame is laid to the entire height of the foundation.

Concrete is poured in layers of 20 cm. It is imperative to tamp each layer with wooden rammers. After a week, you can remove the wooden formwork and coat the outer layer with bituminous mastic. The sinuses of the strip foundation are filled with sand, which is carefully compacted and spilled with water.

In order for the house to be strong and durable, you need to correctly calculate the foundation. This takes into account the entire load: constant from the house itself and temporary - from the snow cover. An accurate calculation can be made only taking into account the soil of the area.

First, we calculate the approximate weight of the house. To do this, we take the average values of walls, ceilings and roofs. For example, 1 m 2 of a wall made of timber and logs weighs about 100 kg, brick walls up to 270 kg. One sq. a meter of attic flooring along beams with insulation has a weight of about 200 kg, and reinforced concrete - 500 kg.

One sq. a meter of sheet steel roofing has a weight of 30 kg, and a slate roofing weight of 50 kg / m 2

Let's say you are building a two-story 6x6 house, then the outer walls will have a length of 24 meters, and together with the inner one - 30 meters. The basement floor area is 36 m2, and the roof area is 49 m2 with projections of 50 cm on each side.

We take into account the average snow cover that occurs in the area. For example, for the south of Russia it is 50 kg / m 2. And in the middle lane - 100 kg / m 2.

That is, the load on the foundation will be about 55 tons for a brick house, for a reinforced concrete house - 97 tons, and for a frame house - 22 tons. Under a brick and reinforced concrete house, a deeply buried strip foundation will have to be laid.

To determine the load on the ground, you need to add the weight of the foundation to this value. In the case of a monolithic reinforced concrete foundation 30 meters long and 40 cm wide, the weight of the foundation will be 54,700 kg. Support area 120000 cm 2 .

To calculate the load on the foundation, we divide the weight of the building by the supporting area. We get the load for a brick house - 0.92 kg / cm 2. Since any dry soil has a bearing capacity of 2 kg / cm 2, it means that the soil will withstand the load from the structure.

A complete and accurate calculation of the size of the foundation of a house can be performed by specialists involved in the design of houses.

The fireplace is quite an old, but still relevant piece of furniture. Once it was used as a device for space heating and cooking, but recently it can also combine decorative functions.

The fireplace has a considerable weight, so it needs a separate base. The foundation for the structure can be made using various technologies, but installation in a wooden house has special rules and requirements.

A fireplace that performs only decorative functions does not need a separate foundation. A mandatory foundation requires only a full-fledged design, the hearth of which will be used on a regular basis.

Requirements for installing a fireplace

The first thing to pay attention to when installing a fireplace in a wooden house is fire safety:

1. Do not install a fireplace in front of window and door openings. The flow of fresh air can cause a fire or an uncontrolled increase in fire.

2. The fireplace design should be in the largest room. Installation in a small room threatens with oxygen deficiency for households, as the fire will actively "suck" it out of the air.

3. You can not install the fireplace directly on the floor or logs. In addition to the fire hazard of wooden floors, there is a possibility of their deformation caused by the pressure of a heavy fireplace structure.

4. The combustibility of wood requires the installation of a structure located separately from the wall or the laying of a brick sheet.

Varieties of foundations

Foundation construction methods depend on when the fireplace was installed. The simplest and most convenient is the construction at the same time as the construction of the house.

The system of the hearth, firebox and chimney has a decent weight, so the shrinkage of the foundation under the fireplace will be greater than the subsidence of the entire log house. In this regard, it is not necessary to equip the firebox earlier than a year after the completion of the installation.

If the construction of the foundation will take place several years after the construction of the dwelling, then the installation can take place in two ways: simple, but not too reliable, or complex, but safer.

The first method consists in choosing the location of the structure and fixing the reinforced concrete or iron partition on the ledges of the main foundation.

According to the second method, it is necessary to remove the floor and equip a small but full-fledged foundation, which should not come into contact with the base of the building. The new facility involves digging a trench, laying rebar and pouring concrete.

Features of the formation of the foundation

Before starting work, make sure that the foundations of the fireplace and the main building will be located at a distance of at least 5 cm from each other. The resulting gap is filled with ASG or other loose mass, thereby ensuring the independence of the two bases.

Pit

The depth of the foundation depends on the level of freezing of the earth, but should be at least 50-60 cm. The perimeter of the pit must be dug 10-15 cm more than the final structure.

For independent production of a trench for the foundation in a finished wooden house, you will have to make a lot of effort, since the soil layer under the building can be significantly compacted.

A layer of sand and gravel (each 5 cm) is poured into the dug hole, rammed and covered with a reinforced mesh and pieces of reinforcement.

Foundation

When choosing a specific type of base for a fireplace, it is necessary to focus on the characteristics of the soil, the mass of the structure and the convenience of work.

Concrete or refractory brick

The foundation itself can be made of refractory bricks or rubble concrete. The concrete option requires the manufacture of formwork with waterproofing, into which large and small stones are then placed and poured with concrete mortar.

brick monolith

Another version of the foundation for the fireplace is a brick monolith. Its manufacture requires significant financial investments and construction skills. Brickwork is best done with a solution of lime and water (1: 3) with the addition of the right amount of sand. All buried parts of the foundation must be protected from liquids. This can be done using oily clay, diluted to the density of sour cream and applied to the base.

Plate

The slab base under the fireplace is recommended for complex soils with high groundwater, as well as for massive structures. During its manufacture, it is necessary to lay a reinforcing mesh in the pit and fill it with a solution consisting of 1 share of cement and 4 shares of gravel. Then close the concrete with roofing material and wait until it dries completely.

Any foundation for a fireplace in a wooden house should be 50-60 cm above the ground and 6-7 cm below the floor level.

piles

The pile foundation contains 4 supports and consists of asbestos or reinforced concrete pipes. When calculating their cross section, it is necessary to take into account the mass of the fireplace structure. Its average value (together with the chimney) is 4-4.5 tons, so the diameter of each pile should be approximately 15 cm.

Conclusion

Features of creating a foundation for a fireplace in a wooden house depend on the weight of the hearth and the characteristics of the soil. An incorrectly chosen foundation threatens to repair or even restore the entire structure, which will require considerable cash costs. A high-quality and durable foundation can only be obtained if all technological standards and requirements are met.

The use of a fireplace in the interior of the premises has come to us since time immemorial, but has not lost its relevance even now. It is most common in country mansions.

The fireplace is a rather bulky structure, therefore it requires a reliable and strong foundation. Its weight can exceed one ton, respectively, an increase in size will entail an increase in mass. And this, in turn, implies that the fireplace must be installed on a solid foundation, so that it can be safely operated for many decades.

If you follow certain rules and observe fire safety when using a fireplace, you can perfectly warm up the house and get aesthetic pleasure from contemplating the flames. However, for this, the fireplace must be made in accordance with all regulations, and it is also necessary to use certain and clearly defined types of fuel, which must be correctly put into the furnace.

It is forbidden to light the fireplace with garbage and waste. For these purposes, only special fuel is used, otherwise the chimney may become clogged and other negative consequences may occur. In addition, reliable, safe operation of the fireplace for many years is possible only if there is a powerful foundation.

Manufacturing specifics

The base can be built from various materials. However, it is important to maintain a gap of 50-55 mm between the building of the house and the fireplace. Compacted sand should be filled into the gap.

The base can be built from various materials. However, it is important to maintain a gap of 50-55 mm between the building of the house and the fireplace. Compacted sand should be filled into the gap.

The need for an additional foundation is based on different loads. It would be optimal to provide for the construction of a foundation for a fireplace even before starting to build a house.

In addition, if in a wooden house, then it is required to carefully observe building codes, since this creates a fire situation and can lead to a fire.

Creation rules

Work begins with digging a pit, the dimensions of which will be 10-15 cm larger than the size of the foundation. The depth of the pit varies between 60 centimeters for a one-story building and 70-100 cm for a two-story building.

At its bottom there should be no irregularities. Bookmarking should be carried out in layers: for these purposes, small crushed stone or stone is used. The solution is poured by 20-25 cm. The distance between large stones should be 3-5 cm.

Note: the technology provides for the presence of strictly vertical walls at the foundation with an upper horizontal platform.

The upper part of the base can be made:

The upper part of the base can be made:

- level with the floor;

- near the floor;

- go down 15 cm lower with the aim of subsequently leveling it and making the first layer of brickwork.

Masonry is performed in two rows with two layers of waterproofing. If everything was done correctly, the level of the finished foundation with the subfloor should match and be at the same height.

The use of rubble concrete

For the construction of the base of the fireplace with your own hands, rubble concrete is perfect.

For the construction of the base of the fireplace with your own hands, rubble concrete is perfect.

For these purposes, formwork should be made, which is sheathed from the inside with roofing material, roofing felt or bergamine, or treated with bitumen. Filling is performed in several layers.

The first layer is made up of large stones up to 15 cm. Gaps are left between them, into which crushed stone is poured. The top layer is made from a mortar in a ratio of cement to sand 1: 3. Next, a solution is prepared from which the base will be, prepared in a 1: 1 ratio of water with cement. The pouring of rubble concrete is carried out in rows, it is desirable to do one row per day.

concrete foundation

Portland cement, gravel and sand are used to create it.

Portland cement, gravel and sand are used to create it.

The first pit is dug, a reinforcing mesh with dimensions of 10-15 cm is laid in it. Next, a solution is made in a ratio of 1: 4 and poured into the pit.

Filling should be carried out in two stages, two days later. Formwork can be removed after a week. If there are defects on the surface, then additional waterproofing must be done. For these purposes, various solutions of cement and fine sand are used.

With the use of piles

If a deep foundation is required, a four-post pile structure should be used.

If a deep foundation is required, a four-post pile structure should be used.

The fireplace is installed on piles, which are interconnected by a concrete screed.

For the manufacture of piles, asbestos-cement pipes or reinforced concrete are used. In the first case, they are additionally reinforced using steel rods. The total weight of a brick fireplace, taking into account the stove, will be approximately 5-6 tons. This is important to keep in mind when calculating and planning.

After the base has been prepared, a fireplace should be erected, which includes a base, an ash pan and an air duct.

Foundation types

The following types of foundation for a fireplace are mainly used:

The following types of foundation for a fireplace are mainly used:

- Solid foundation. The material here can be: gravel, small stone, brick rubble. Leave a gap of two bricks between the supports. Such a foundation is used in the construction of a fireplace in a wooden house.

- The columnar foundation is used in the construction of classic and modern fireplaces. It can be mounted close to the wall, which creates a special stability. Such a foundation can be made in corner rooms, despite the size.

How to tie to the floor

Connecting the foundation of the fireplace to the floor, if you follow certain rules, will not be difficult.

Connecting the foundation of the fireplace to the floor, if you follow certain rules, will not be difficult.

First of all, you need to decide what material the foundation will be made of, then decide on the location, then carry out mathematical calculations and start laying the foundation. If the traditional type of concrete is chosen as the foundation construction, then temporary formwork is performed and the building mixture is poured.

During the day, solidification occurs, the base becomes solid and gains strength, which means that it will be possible to use such a fireplace for a long time.

It is important to know: For safety reasons, flammable objects should not be placed near the fireplace. It is best to place them at least a meter away from the fireplace, which will protect your home from fire.

Watch the video, which explains the main features of the fireplace foundation device:

Very often, potential buyers of fireplaces ask themselves: is it necessary to do in the house for this hearth? foundation. There are a great many models of fireplaces, among which there are light and heavy hearths. For fireplaces, whose weight is 350-500 kg, it is not worth creating a foundation, not only that, such fireplaces can be installed even on the second floors of the building and subsequent ones, because such a weight does not carry a significant load on the floors. Another thing is when the fireplace weighs about a ton. In this case, it is imperative to create a very strong separate base so that the fireplace lasts as long as possible and does not start to sink into the ground.

Digging a pit

The construction of the foundation begins with the digging of a foundation pit, the dimensions of which should be 10-15 cm larger than the foundation being laid. For a one-story house, the depth of the pit should be about 60 cm, for a two-story house, 70-100 cm, or correspond to the value adopted during the construction of the foundation of the building.

If the soil is non-porous, then a leveling pad of sand is made at the bottom of the pit. With heaving soil, the pillow is made from a mixture of sand (40%) and gravel (60%). The anti-rock cushion is placed in layers with constant moisture, tamping with a manual or automatic rammer with checking the horizontalness of the base using a level. The height of such a pillow should be similar to the height of the foundation of the building itself.

Before making a pillow, the bottom soil of the pit should be leveled and compacted. The pillow is laid on non-moist soil, and if it suddenly rains and puddles form during the work, they are scooped out, and the layer of earth, which has become fluid and plastic, is cut off to its original state. Usually the height of the cut does not exceed a few centimeters.

If groundwater does not enter the finished pit and the walls do not crumble, then the foundation for the fireplace can be made of rubble concrete or brick.

concrete foundation

During the construction of a fireplace concrete foundation formwork must first be made. The inner walls of the formwork surface are sheathed with roofing felt or roofing material, or coated with bitumen. This is done so that the cement milk from the concrete mixture does not go into the sand. Next, the formwork is placed on the prepared base and the first layer of stones is laid in it. Stones must be at least 15 cm in diameter. The voids between the stones are filled with rubble. From above, all this is abundantly poured with cement mortar, consisting of 1 part of cement and 3 parts of sand. Then a creamy mixture of sand and cement is prepared with the addition of water. Water and cement are taken in equal proportions. Rubble stone is poured with this mixture. The first layer of stone is poured on the first day, the second and all subsequent ones are poured with an interval of one day. It is necessary to lay each new layer of rubble stone only after the previous layer has hardened. The last layer must be leveled and covered with polyethylene. The foundation made should be 60-70 cm above the floor level. Laying a fireplace on a new foundation should begin no earlier than a week.

concrete foundation

Fireplace construction concrete foundation start with the preparation of a mixture consisting of one part of Portland cement and four parts of a sand and gravel mixture. Concrete is poured into the pit in two layers. After filling the first portion, reinforcement is laid on it, covered with a small layer of concrete and rammed. The mesh size of the reinforcing mesh should be 10-15 cm. Then the rest is poured. After about two days, the concrete completely hardens and is ready for formwork removal. In summer, formwork is stripped after 4-6 days, in winter after 8-12 days. After removing the formwork, concrete is recommended to be watered for some time to increase the quality of the concrete. Before starting work on the construction of a fireplace, it is necessary to inspect the foundation for a defect. If flaws are found in the form of small pores and shells, additional waterproofing is carried out. If there is no groundwater, then plastering or cementing is carried out, and then non-porous soil is poured into the sinuses of the pit.When laying the foundation deep, four supporting piles should be driven into the pit, which are combined from above with a reinforced concrete screed. Piles can be made of reinforced concrete or asbestos-cement pipes, which are reinforced inside with metal rods and filled with concrete. Foundation for a fireplace be sure to make high-quality, otherwise in the future you will have to increase the cost of the fireplace, which may begin to settle and, as a result, cracks may occur, the facing tiles may fall off the portal and other troubles.

Installing a fireplace on a console

If there is no option to build a fireplace or stove on the foundation, and the floors are weak, then you can mount the structure on consoles embedded in the load-bearing walls of the house. It's tricky, but not hopeless. First you need to prepare two steel beams (taurus, channel bars, pipes, rails), in general, anything of a sufficiently large cross section (from 120 mm high and more).

Two holes must be punched in the bearing wall, 100-150 mm larger than the section of the prepared beams. The beams are then inserted into the holes and concreted. An arch is laid out between the beams, which serves as the basis for the fireplace. Immediately after installing the consoles, it is not recommended to start laying the fireplace. Duration of endurance of durability of 28 days. It is not necessary to wait so long, but at least two weeks it is not worth loading the seal. Beams, of course, will not fall out of the wall, but they can squint. The depth of the foundation depends on many factors: soil, location, climatic conditions (depth of soil freezing), etc.

Soil freezing depth

In central Russia, 1 meter of depth is usually enough for a foundation for a stove inside a house. The depth of laying a foundation for a barbecue should be determined according to the zoning map SNiP 2.01.01-82 "Construction climatology and geophysics".

Calculate the depth of soil freezing

Interactive table for calculating the depth of soil freezing in the following cities: Omsk, Novosibirsk, Tobolsk, Petropavlovsk, Kurgan, Kustanai, Sverdlovsk, Chelyabinsk, Perm, Syktyvkar, Ufa, Aktyubinsk, Orenburg, Kirov, Izhevsk, Kazan, Ulyanovsk, Samara, Uralsk, Vologda , Kostroma, Penza, Saratov, Tver, Moscow, St. Petersburg, Voronezh, Volgograd, Guryev, Pskov, Smolensk, Kursk, Tallinn, Kharkov, Astrakhan, Riga, Minsk, Kiev, Rostov-on-Don, Dnepropetrovsk, Frunze, Almaty , Kaliningrad, Lvov, Nikolaev, Chisinau, Odessa, Simferopol, Sevastopol.

Soil freezing calculator!