Filters for heating systems. Which ones are needed? Dirt trap for the heating system Filter for the heating radiator of a gas boiler

Filters for heating systems ensure the quality of the coolant inside the circuit.

This prevents the formation of rust on steel structural elements, which extends its service life.

They are divided into coarse filters, fine filters and magnetic devices.

What are filters for home heating systems?

Such devices have another name - mud collectors. Externally, they represent a pipeline expansion unit with a change in the direction of fluid flow and with a special mesh.

She prevents further movement of suspended particles through the pipeline. The devices are installed in such a way that maintenance is easy.

Types of devices

According to the degree of cleaning of mud collectors classified into several types.

Rough cleaning. What is a sediment filter?

The coarse cleaning device is an angular mesh filter with mesh up to 300 µm-micron. The device is also equipped with a drain in which dirt accumulates. This product is designed to clean coolant from large and small fractions.

Design

Depending on the design there are several types coarse mud collectors:

- By connection method devices with a pipe. There are flanged, welded and threaded devices.

- By location on the structure. This is a horizontal and vertical device.

The mudguard is made of brass, steel and plastic. The first option will withstand elevated temperatures. A steel device wears out quickly. A plastic product can only withstand relatively low temperatures up to +90 degrees Celsius.

One of the types of coarse mud filter is settling filter. This is an improved design equipped with a flask. It is located at the bottom of the device. When a large amount of dirt accumulates on the mesh, it falls down under gravity. Thanks to this, such debris accumulates in the flask and does not end up in the radiators.

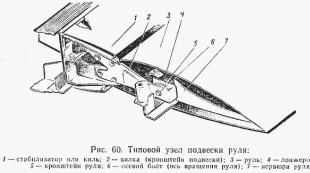

Photo 1. Coarse settling filter for heating systems. Contaminants from the pipes fall into a special flask.

The design is also being improved separator. Air accumulates in it and enters the circuit. When its level reaches the limit, a valve opens on top of the device. After this, the air leaves the system, which prevents the formation of air locks.

Operating principle

There is a mesh inside the filter. This the element blocks the inlet, along which the coolant moves. During the passage of liquid through the mud filter, medium and large sized fractions are cut off. After this they move to the outlet. Thanks to this, relatively clean coolant flows to the radiators.

Advantages

Improved designs have the following advantages:

- Thanks to the flask, there is no need to remove the device to assess its degree of fullness. The assessment is carried out visually.

- A tap is fixed at the bottom of the device. Dirty water is drained through it.

- The filter removes air from the system, which prevents rust from occurring. This extends the life of the circuit.

Installation location and features

The installation location of the device depends on what heating system is it used for? For autonomous circuits, it is mounted at branch points, on the return before connecting to the boiler and on bypasses.

Normal operation of the device guarantees correct installation. Before installing any device, the circuit is cleaned of dirt and rust.

There are special symbols on the mud pan that indicate the movement of liquid through the pipes.

The product is installed only in accordance with this guide.

If the mechanism is not fixed correctly, hydraulic resistance will arise inside the structure.

Attention! The mudguard provides the circular pump with protection against debris from penetrating the blades. If you refuse to use it or install it incorrectly, then the likelihood of engine and impeller failure will increase.

You might also be interested in:

Fine purification for water

Fine mud filter is additional filter, designed to remove small fractions.

Design

There are several designs of such a device:

- with metal mesh up to 5 microns-microns;

- with a cartridge made of fabric folded in several layers;

- with polymer porous filler;

- with mineral sorbent backfill.

Operating principle

The operating principle of such filters: water passes through the cassette and small fractions settle on its surface.

After this, the coolant moves through the pipeline without contamination. A fine mud filter cannot cope with large fractions, so it is not used as an independent filter. It's just the last stage of the cleaning system heating circuit.

Advantages

The main advantage of the filter is that it cleans the coolant from small particles of dirt. This increases the service life of the circuit, since the risk of corrosion is reduced.

Where and how is it installed?

Such a mud man installed on horizontal pipes. It is located between the taps to block the flow of water during maintenance.

Important! If the heating system does not use water, but antifreeze, then a fine filter cannot be installed, since such liquid does not pass through this device well.

The mud trap for fine cleaning is mounted on the pipe in the direction of water flow. There is no other way to install the filter.

Fine cleaning devices reduce the risk of an emergency.

Magnetic models of mud collectors

A magnetic filter for a heating system is a device made of two magnets with polar poles that are placed opposite each other. This device cleans the coolant not from pollution, but from metals.

Photo 2. Magnetic filter for cleaning heating systems from metals. Installed on a pipe.

Design

By design there are two types magnetic filters:

- Removable model. This device consists of two plates that are fixed on the pipe. The advantages of the device are that it is quickly replaced and easy to install.

- Non-removable mudguard. It is a pipe made from ferromagnetic alloys.

Operating principle

Opposite poles of a magnet attract metals present in the coolant. Once within the filter's coverage area, they settle on its surface.

Advantages

Advantages of a magnetic filter:

- the device slowly becomes dirty, so it is not cleaned for several years;

- prevents the formation of scale on pipes and radiators;

- increases the service life of the heating circuit by freeing the coolant from metals.

Installation rules

Device mounted only in front of the circulation pump. A place with the same cross-section of pipe and sump is selected.

Most modern homes use gas for heating. Some receive heat through a central heating system, others prefer to independently control the process of heating their own home, so they choose. Boilers that run on gas are also used for this.

Gas is popular because of its economy and efficiency as a heat source for or. It is also preferred due to its inability to negatively affect the equipment, that is, the boiler itself. But sometimes situations arise with a malfunction of the system or individual parts. To reduce the risk of breakdown to a minimum, additional equipment is used in boilers, for example, boiler filters or burners (also gas).

To fully understand why additional components are required, you should familiarize yourself with the general operating principle.

In a central heating system, as a rule, pipes that are made of high quality steel are used to supply gas to the house. In an individual heating system, owners prefer to replace steel pipes with special hoses. In terms of their properties, they are in no way inferior to pipes, but are much more practical (they are easy to hide, unlike pipes, which will spoil the appearance of the wall in the kitchen).

After passing through the pipes, the gas enters the burners. This is where it ignites. Technologists distinguish two types of ignition: open and closed fire.

To obtain an open fire, there are several common and proven methods. All of them can be used in heating boilers.

- A way to start a fire with your own hands. Fortunately, this method is used extremely rarely in the modern world, because it has long been outdated, giving way to newer and more practical ones.

- Using piezo ignition. A pilot light that is lit will easily ignite from the slightest spark.

- Using electronic ignition. It is this method of ignition that has become the most popular as a result of technological progress. At the same time, it is also the most effective way to light a boiler. This method has only one drawback: its operation is impossible without electrical energy.

Now it becomes clear that a modern boiler is a complex device, which in its structure has three components: gas, water and electronic.

Several factors can disrupt the operation of the boiler:

- the gas supplied through the pipes is of poor quality;

- the water that is pumped into the system is very hard;

- Currents wander in the gas pipeline due to instability of the voltage in the network.

To avoid damage caused by these factors, it is necessary to use protective devices.

To protect against voltage surges, it is recommended to install stabilizers designed specifically for boilers.

Filter – protective device for boilers

And to protect the heat exchanger from exposure to hard water, you will need to install a filter. This will prolong the operation of the boiler and protect it from harmful influences.

The water contains metal salts. They make the water hard and promote scale deposits. The scale that covers the surface of the heat exchanger acts as thermal insulation. It impairs the heat transfer process. Thus, the heat transfer of the heating elements deteriorates, which accordingly leads to overheating and breakdown of the heat exchanger.

Before the device breaks down, scale accumulation has other consequences:

- Significant overconsumption of electricity and gas begins. To operate, the boiler uses more and more of them, but this does not increase operating efficiency.

- Water nodes significantly reduce their throughput.

- Water heaters with automatic valves reach a pre-emergency state. There is an incomplete opening or, conversely, closing of the valve that is responsible for the water supply.

The filter is always installed at the point of water supply to the boiler. Before water enters the system, it will pass through the filter gaskets, which will retain the components included in it. All filter gaskets have a mesh structure. This will allow you to retain even small components. Due to their high ability to purify water, such filters are called fine filters.

Specifics of magnetic filter operation

To protect the internal components of the boiler from mechanical scale, it is recommended to use another filter. It is installed after the fine filter. We are talking about a magnetic filter. More precisely, this device is used for magnetic treatment of water.

It is recommended that the flask included in the filter be washed periodically. Otherwise, it will fill up and the filter may fail. Dirt will accumulate in the flask. It needs to be removed. It will be enough to wash off the dirt with a stream of water. You can rinse it right away in the sewer, if the filter design allows, or you should place a vessel and carry out the procedure of washing the cone over it.

Passing the mesh and magnetic filters, the water will be highly purified, which will protect the boiler from scale deposits on its constituent components. The scale will not disappear miraculously. It’s just that instead of large deposits, scale will turn into sediment in the form of small crystals as a result of passing through the filter. In this form, the sediment will be easily removed from the system without causing any harm to it.

Also, a magnetic filter can also provide preliminary protection of the heat exchanger. When treating water with magnetic radiation, not only does scale disintegrate, but also the internal surfaces of the pipes and exchanger are covered with a protective layer in the form of an oxide film. This film will become a protective mechanism for the pipes before the corrosion process, which is also detrimental to heating boiler devices.

The above filters are considered as components of a heating boiler, but the filter can also be installed as a separate device. Such devices were also carefully designed so that their work brought no less effective results.

To neutralize the effects of hard water and eliminate the consequences of its effects, water treatment is used by stabilizing its components. For this purpose, special means are used, which are called complexons.

Most household filters are filled with ion exchange resin. In technical language, such a filler is called anion exchanger. This resin is treated with complexions before being introduced into the filter. All substances used to process resin are completely harmless and have no negative impact on human health.

By using an anion exchanger to fill the filter, you can evenly process the water that enters the heating element. This also ensures the stability of the filter. The result of such work will be the absence of scale on all elements of the heat exchanger.

Using a filter with this operating scheme, you can achieve the following results:

- plaque and scale will not form on the surface of the heat exchanger, since the operation of the filter will interfere with this;

- if deposits have already appeared, then complexions will help get rid of them;

- thus, heat transfer will improve (after all, the operating conditions of the coolant have also improved);

- this affects the reduction of electricity consumption;

- Accordingly, the service life of heating equipment will increase;

- acts as additional protection against the formation of rust stains inside pipes;

- There is also no need to pre-soften the water.

Benefits of boiler filters

- Extends the life of the boiler.

- Completely harmless to humans.

- Does not have a negative impact on the environment.

- Allows you to save 10-20% of electricity.

- Does not require the use of additional filters or protection against scale and hard water.

- The reliability of protection provided by the filter remains equally high throughout its entire service life.

- Significantly reduces the amount of heavy materials that are part of tap water.

- Chlorine and hydrogen sulfide, which are also components of water, significantly reduce their activity as a result of filtration.

The result of these advantages will be complete protection of all heating elements of the boiler from the formation of scale or the appearance of various other deposits. Rubber seals are also protected. They wear out less if they are not exposed to hard water. Of course, the equipment (boiler, boiler) will last much longer and more efficiently.

This is what a filter element looks like, designed for installation in heating systems where hot water is used as a coolant. This is an important element in the heating system, as it ensures its uninterrupted and trouble-free operation.

It is designed to trap small particles of debris and water impurities, preventing them from entering the pump or boiler, as this can lead to consequences such as failure, the need for repairs, etc.

Today on the market there are samples of straight and oblique filters that are mounted directly into the main pipe. Both options are equipped with a mesh inside with very small cells (800 microns), which retains even the smallest particles of debris in the coolant

Design features

From the name itself it is clear that a filter for a heating system is an element that is responsible for the cleanliness of the incoming coolant.

According to the principle of their design, they are divided into the following types:

- Coal;

- Mechanical;

- Electronic.

Carbon is designed to remove unpleasant odors, mechanical is capable of trapping small particles up to 0.3 microns in size, electronic – up to 0.01 microns. That is, all types of small particles of debris are removed, which can accumulate in the boiler and cause failure of the heating equipment.

It can be:

- sand particles;

- tiny particles of rust;

- lime deposits;

- dust containing various components;

- gaseous impurities, etc.

Installation and maintenance features

It is quite possible to install the filter with your own hands, but there are several important points that you should familiarize yourself with even before installation work. This will allow you to do everything correctly, even if you are not a professional in this field.

Important! A heating filter is installed only in front of the pump in the home heating system! Installation in another place is simply pointless, since coolant with particles of dirt and sediment will still get into the pump and boiler.

Heating filters can have different circumference diameters (15-100 mm), the choice depends on the diameter of the pipes in the place where installation is to be done. It must be installed in a vertical position, on special brackets.

- Before installation, you should thoroughly clean the heating system pipeline from rust, scale, metal particles and other types of contaminants;

- When choosing filters for a heating system, you must remember that it must correspond to the conditions of the working environment where it will be used (medium, temperature, pressure);

- For installation, it is recommended to choose a place that is as accessible as possible for inspection and maintenance in the future (not forgetting the technical requirements for the place of its installation - on the “return”, in front of the pump!);

- It is important that the diameter of the hole exactly matches the diameter of the pipes at the installation site. This will ensure reliable installation and eliminate the occurrence of mechanical stresses in the future (distortions, stretching, bending, etc.)

Maintenance and cleaning

Cleaning the device is simple:

- from precipitation by reverse flow of water;

- mesh cleaning(the lid is unscrewed, the mesh is pulled out, cleared of accumulated debris and put back in its place).

The mesh is easily removed; there is no need to completely dismantle it. This makes it easy to tackle the cleaning task yourself.

Advice: cleaning must be carried out at least once every six months. Only in this case can we talk about the effectiveness of using the filter element.

Why is it worth installing a filter on your heating system?

Many users may quite logically be interested in the question of whether it is necessary to install filters for heating systems? It is worth noting that even without organizing cleaning, the equipment can function normally, another question is how long?

First of all, such an installation is necessary to ensure reliable and uninterrupted operation of heating equipment, eliminating emergency situations and failures.

The price of heating filters is not so high; its timely purchase and installation will cost much less than later repair or replacement of heating elements. Not to mention the fact that an accident in the heating system will lead to such unpleasant consequences as cold and discomfort in the house (after all, it is during the cold season that the thermal regime must be maintained).

The advantages of the installation include:

- reliable protection of the system from blockages;

- it is not necessary to change the water (coolant) so often;

- the service life of heating equipment is extended;

- cost savings;

- confidence in the reliability and uninterrupted operation of the system.

Conclusion

It is enough to watch the video, which describes the installation technology, to understand that there is nothing complicated here.

Practicality and a reasonable approach will ensure rational and justified savings of money, time, nerves and effort for the owner!

Each of us has a heating system at home. It is impossible to imagine any modern home without heating devices that provide full temperature conditions at any time of the year.

However, you need to remember that it is not enough to simply install a pipeline, connect the boiler to it and put it into operation. It is also necessary to take care of the quality of the water inside the pipes. A filter for the heating system copes well with these tasks.

What is a heating filter, why is it needed and what is it like? Let's figure it out now.

Why is it needed?

Let's imagine the design of the pipelines of an ordinary private house. Its heating system in 95% of cases consists of pipes and radiators that transport hot water.

Heating a house using pipes and water is an extremely convenient and effective way. However, many people forget that, just like when working with pipe systems for water supply, heating pipes and the heaters themselves also need to be protected from working with low-quality media.

Unfortunately, we cannot guarantee the quality of the water in the pipes, even if we get the bulk of the water from a well drilled ourselves.

Tap water often contains coarse and small particles of dirt, sand, small fractions of waste, chlorine, etc. Let's not forget about small organic waste or various metal elements.

The same applies, although to a lesser extent, to the quality of water from a well. It also happens that a well was not drilled in the best area. For example, the soil on your site has too much iron. In this case, the water will gradually become saturated with small iron elements, which negatively affect the insides of the pipes in the heating system.

But this is only a superficial analysis of several reasons why you may need a water purification filter.

1.1 What happens if you don’t install a filter?

Many people will ask, why do you actually need a heating filter? What's the use of it? This is not a water supply system, the water from which we constantly use for personal needs, hygiene, food, etc.

These questions are very reasonable. We will try to answer them. The main thing you need to understand is the importance of the heating system as a structure. Few people pay attention to it, especially if there are no breakdowns inside the house. However, believe me, if the heating system of a private house fails, you will notice it immediately.

There are several vulnerable points in heating pipelines:

- Heating circuit pipes;

- Circulation pump design;

Heating pipes are no different from water supply pipes. Except perhaps for a slightly reinforced structure, because their task is to constantly transport hot water.

They also suffer from poor-quality or dirty media, rust, and become clogged with waste. Considering the need for uninterrupted pumping of large masses of hot water, the rate of sedimentation even increases.

Sooner or later, the space inside will become so clogged that the passage of liquid through it will simply become impossible. The pressure inside the system will increase, which can lead to the most unpleasant consequences (take into account the influence of hot water) up to a breakthrough or failure of heating devices.

The same applies to radiators. Although the radiator cavity still suffers less from precipitation.

The design of the circulation pump suffers in a similar way. Unlike pipes, the chamber and inlets of the circulation pump are almost not subject to the negative influence of sediment, but large particles of debris and metal elements can create problems for them.

Over time, the condition of a circulation pump operated in a poor-quality environment will greatly deteriorate to the point of complete failure. This is why many plumbers recommend installing mud filters or coarse filters in front of the inlet chamber of any pump, especially a circulation pump.

However, clogged pipes, radiators or failure of the circulation pump are not such a big problem. In any case, it can be solved by simply replacing individual components or cleaning them.

What cannot be dealt with so quickly is a boiler breakdown. It does not matter whether you use an electric or gas heater, in any case it must be limited from working with contaminated liquid.

Without complete cleaning, the water in the heating chamber and tank will gradually clog the insides of the boiler. This will lead to a deterioration in its functional characteristics, frequent overheating, and in particularly advanced cases – to breakdowns.

2 Where to install?

Let's figure out where and how the heating filter should be installed. Installing the filter depends on what device we are going to install.

The coarse filter is used the least, but you can’t do without it. Mud collectors, as they are popularly called, must be installed so that they sift out large waste from all the liquid that enters the heating system.

It is advisable to install a coarse filter at the inlet of the system or at the inlet to the pump structure. If the pipeline is large, with a huge number of radiators, then it is recommended to install mudguards at all forks, especially between floors.

Fine filters perform more specific tasks and more of them are needed per pipeline as a percentage. They work best in tandem with mud collectors, but only if they are installed after the first ones.

A magnetic filter, which performs rather specific tasks of removing metal particles from the flow, should be mounted at the entrances to the system, and also for safety, in front of the heater inlet pipe.

2.1 Types and differences

When choosing a filter for a boiler, you need to pay attention to its types. We have already partially noted several of the most popular types of filters.

There are filters:

- Rough cleaning;

- Fine cleaning;

- Magnetic.

Let's look at each option separately. Let's start with samples for rough cleaning, since not a single heating circuit of any private home can do without them.

Coarse filters or mud filters are simple fittings that filter out excess particles from the flow inside the circuit.

Screening is carried out by a mesh element. The filter itself is a coupling with an oblique design. Inside the coupling there is a mesh filter, and also, if you have a modern model, a small outlet for waste accumulation.

The mesh element does not interfere with the movement of the flow in any way and does not slow it down in any way. Its task is to remove large foreign particles, that’s all.

The fitting for fine cleaning is usually installed after the mud trap. A mesh or membrane filter with small pores is already installed on it. The average pore diameter is 100 µm.

Thus, the device manages to filter out most of the waste that can then turn into sludge. These include various magnesium salts, particles of chlorine, rust, etc.

It has been proven that the presence of coarse and fine filters has a positive effect on the condition of pipes and radiators in heating systems.

It remains to consider the magnetic sample. The magnetic filter is somewhat different from those we discussed above. In it, the main work, as is probably clear from the name, is carried out by a magnetic mechanism.

The magnetic sample performs a simple and very useful task - it removes all remaining particles of iron and rust. Moreover, it does this thanks to two or four magnets located inside the coupling.

The benefits that a magnetic cleaning device brings to the heating circuit and boiler can hardly be overestimated.

2.2 Using coarse cleaning filters for heating (video)

2.3 Installation and maintenance

We will give some tips on how best to use a combination of cleaning devices to maximize the service life of heating systems in a private home.

From our point of view, it would be correct to use all types of filters. Don't skimp. The cost of a filter is slightly more than the cost of a regular fitting, but repairing or cleaning pipes will cost you much more.

We recommend installing a coarse filter at the system entrances. If the flow is small and goes through a single pipe, then one sample is enough. Otherwise, it would be correct to install one filter in the liquid pumping station directly next to the pump, and the second at the inlet to the heating circuit.

Magnetic filters are mounted directly in front of the entrance to the heating circuit pipes and additionally on the inlet pipe to the heater.

The cleaning elements must be cleaned from time to time, and if they are too clogged, they must be completely replaced.

It is advisable to remove the parts once a season, preferably in the summer, wash them under running water and change the cassettes if necessary.

Monitor the condition of the membranes and meshes inside the couplings. Loss of ductility and excessive convexity indicate excessive wear of the membrane. In this case, it needs to be changed.

When it comes time to think about the heating system in your home, a lot of technical questions arise. Of course, you want to do everything correctly, thoroughly and inexpensively. But it’s not enough just to properly plan the system itself; you also need to take care of the water flowing in the veins of your home. Excessive water hardness and abrasive impurities in it can shorten the life of your system by decades. Today there are many ways to purify water. And you definitely shouldn’t skimp on them. Savings here will entail large expenses in the future, including replacement of machinery and equipment. When using water from a well or reservoir, several filters must be used to protect the coolant. There are four main and mandatory ones:

- ion exchange resin filter

- cascade mechanical cleaning filter

- universal filter mesh

The uninitiated user, of course, will have natural questions. What are heating filters for, are they useful, do you need to use them all at once and at what stage? The questions are natural and require a detailed answer. It is worth planning the installation of filters at the design stage of your home. It is necessary to allocate space for them, taking into account installation and maintenance. Provide a connection system. If the moment was missed, the filters can be installed later, but this will entail additional labor costs. Therefore, if you are still at the planning stage, it’s time to study each filter in detail.

A flush filter for heating systems is necessary for the mechanical purification of water supplied to a heating system with a working environment temperature of up to one hundred and ten degrees. The filter purifies water from suspended matter, mud and silt deposits, sand, etc. The cascade filter is more compact than other filters with similar functionality. The volume reduction was achieved thanks to the latest nested filter system. Two filter elements of different sizes are placed one inside the other, and the vertically directed water is twisted into a spiral and is effectively cleaned of mechanical impurities. The device is installed strictly vertically. Cleaning the filter elements is quite simple; there is no need to remove the mesh inserts. The body and bulb are most often nickel-plated. Filter elements made of stainless steel. The filter does not take up much space. Simple and reliable in operation.

Universal filter mesh

The simplest mesh filter for heating. It consists of a body (metal) and a cylindrical mesh located inside the flask. The housing is closed with a plug or tap, depending on the type of filter. Connection system - flange. There are washable and non-washable filters. Non-flush ones must be replaced at the end of their service life. The washers last a long time thanks to cleaning. It is necessary to stop the water circulation, dismantle the cover, remove and wash the mesh, and install it. In addition to its relatively low price, the mesh is attractive due to its simple design, easy maintenance and cheap components. This filter is installed in front of the fine cleaning system. This is the penultimate level of protection. Serves to purify water from scale or solid inclusions. Pipe fittings or pumps damaged by scale will cost tens of times more than a cheap filter. The filter does not take up much space.

Coarse filter

The filter is installed when connecting the heating system to the central water supply. It is a flask with a filter element inside. The connection can be flanged or coupling, depending on the diameter of the water supply pipes. Necessary for filtering large contaminants. Effectively retains dirt, sand, large abrasive impurities. It will reliably protect the heating system from large elements, but will let small ones through. It is also not capable of chemical cleaning or water softening. He cannot purify the water to the desired state on his own. Doesn't take up much space. The coarse filter is the first line of defense for your home's water supply.

Ion exchange resin filter

The main component of this filter for heating systems is granular resin saturated with sodium ions. Installed directly behind the coarse filter. Necessary for reducing water hardness. It is known for certain that hard water is a big problem and an immediate threat to all household appliances. The heating system is no exception.

- Softening water will significantly extend its service life,

- It will reduce scale formation or stop this process altogether.

- In addition to scale, the filter is able to combat chlorine impurities, oxidation, iron, and salts.

Such a system takes up quite a lot of space and requires frequent maintenance. When installing, make sure there is enough space not only for installation, but also for routine maintenance. Undoubtedly, such a system is necessary in every home.

In this video we talk in detail about the use of an ion exchange resin filter (watch from 14:15):

To replace the filter loading, you can call a specialist, or do it yourself. When the cleaning system stops working properly, it is necessary to dismantle the system and wash the filler using high water pressure, then load gravel or table salt. Add filler. First turn off the water supply to the heating system and drain the remaining water.

You can choose the right ion exchange resin filter only after analyzing the water. Only by passing the sample to specialists and knowing the composition can you choose a filter that suits its characteristics. Contact the professionals.

Each of the filters takes its place in the chain, complementing each other and jointly creating a single cleaning front. Provide protection for expensive equipment, increase service life and save you money on maintenance. It is recommended to use such a filtration system not only in the heating system. Water treated in this way can be drunk; it significantly extends the life of a washing machine, dishwasher, faucets and other water-related equipment. Equip your home correctly to get the maximum benefit and benefits from modern technologies.